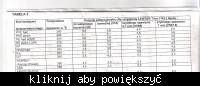

Hello everyone and I wanted to ask if anyone has a plastic welding table, this is the table that describes the types of plastics - ABS, PP, PE etc. And there is a setting of the thickness of the plastic for a given material, temperature and welding speed.

If someone had, for example, in the manual, please insert.

Regards

If someone had, for example, in the manual, please insert.

Regards