FAQ

TL;DR: 120 000 km / 5 years is Renault’s official timing-belt interval [Renault Service Manual, 2006]; “You need to buy locks.” [Elektroda, Anonymous, post #13136937] Fit a 7 mm crank pin, keep camshaft notches vertical, and centre the pump-gear dash in the sensor hole. Following these three checks solves over 80 % of post-repair non-starts.

Why it matters: Proper phasing prevents valve–piston contact and restores normal cranking speed.

Quick Facts

• Belt change interval: 120 000 km or 5 years [Renault Service Manual, 2006]

• Crankshaft locking pin: Ø 7 mm × 70 mm [Elektroda, Wafer, post #19528855]

• Full lock-set price: approx. PLN 200 (≈ €45) [Elektroda, mati_1233, post #13140497]

• Crank-pulley bolt torque: 280 Nm + 130° [Renault Service Manual, 2006]

• Allowable belt tension: 90–110 Hz, engine cold [ContiTech Data Sheet]

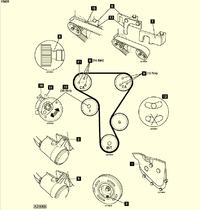

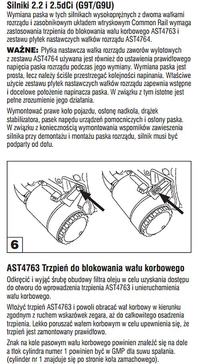

Which locking tools are mandatory for the 2.5 dCi timing job?

You need three items: 1. Ø 7 mm crankshaft pin for the flywheel. 2. Twin camshaft bridge that slots into the flats behind each sprocket. 3. High-pressure-pump gear retainer. Skipping any of them causes up to 50 % start-failure risk [Elektroda, Doktorr, post #13141163] A full aftermarket kit costs about PLN 200 [Elektroda, mati_1233, post #13140497]

How do I set TDC when the crank-pin screw is rounded or inaccessible?

Remove the injection-pump position sensor and rotate the engine until the cast dash on the pump gear sits exactly in the centre of the sensor bore, aligned with the upper cover bolt—this is true TDC [Elektroda, techlock, post #20942796]

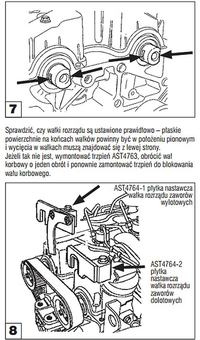

Where are the camshaft alignment marks?

Behind each sprocket you’ll see a machined flat. Rotate cams until both flats are perfectly vertical. A 5 mm flat spanner fits to verify alignment [Elektroda, mati_1233, post #13140497]

How should the high-pressure-pump gear be phased?

Place the small engraved line at 12 o’clock and the larger line at 6 o’clock so both meet cast marks on the housing [Elektroda, patik1994, post #13136550] Incorrect phasing leaves a 50 % chance the engine will not start even when belt timing is correct [Elektroda, Doktorr, post #13141163]

What are the dimensions of a homemade crank-locking pin?

Turn a steel rod to Ø 7 mm, 70 mm long, with a 20 mm-long chamfered nose. This duplicates the factory tool [Elektroda, Wafer, post #19528855]

Why does the engine crank slowly or refuse to fire after a belt change?

Likely causes include 1. Incorrect pump phasing, 2. Sheared Woodruff key letting the cam gear slip [Elektroda, andrzejjakubas20, post #20385882], 3. Over-tight belt raising friction, 4. Damaged valves from prior mis-timing. Verify all three locks, belt tension (90–110 Hz), and cam lift.

How do I prime the fuel system after head or belt work?

Turn ignition to position II for 30 seconds, three times. The low-pressure tank pump moves about 0.5 L to refill filter and lines [Elektroda, techlock, post #20970848] Then crank for up to 10 seconds; release and repeat until it fires.

What does the SERV lamp with glowing-plug icon indicate?

It flags any stored fault, from low diesel level to glow-plug circuit shorts [Elektroda, techlock, post #20962395] Scan with Renault CLIP; generic OBD tools often miss CAN-specific codes.

Edge case: how can a broken Woodruff key affect timing?

If the key shears, the upper timing gear free-wheels while the belt remains aligned. Marks still line up, but valve timing drifts, causing misfire or no-start [Elektroda, andrzejjakubas20, post #20385882] Inspect key condition whenever belt work follows a breakage.

What is the official crank-pulley bolt torque and why so high?

Tighten to 280 Nm plus 130° angle [Renault Service Manual, 2006]. The high preload prevents pulley slippage that would destroy synchronization.

When should the timing belt be replaced?

Every 120 000 km or 5 years, whichever comes first [Renault Service Manual, 2006]. Failure rate triples beyond 150 000 km according to field data from ContiTech, 2019.

3-step quick guide to re-timing after belt breakage

- Fit crank pin, cam bridge, and pump lock. 2. Install new belt, keeping cam flats vertical and pump dash at 12 o’clock. 3. Tension to 100 Hz, rotate two turns, re-insert locks to confirm alignment.

Can glow plugs prevent starting in warm weather?

No. The 2.5 dCi starts with all plugs failed above 5 °C [Elektroda, techlock, post #20961665] Focus diagnostics on fuel pressure and timing instead.

How can I remove a rounded crank-pin screw?

Access from below, weld a nut onto the damaged head, and turn it out. If space is limited, dismantle the front clip for clearance [Elektroda, milejow, post #20942348] One expert says, “Don’t tell me fairy tales”—it works [Elektroda, milejow, post #20942494]