Probably a trivial matter, but I wonder how it should be professionally connected ..

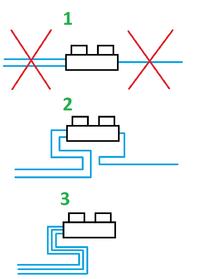

It is about pass-through sockets - on one side there are 3 power cords - on the other side there are 3 wires for the next socket. How to connect them to the socket and let the electricity go on (connect 2 wires on the screws in the socket, are there any cubes or other way ...)

So far, I have always dealt with installations that the main box was above the socket under the ceiling, from where the electricity went on and one wire for each connection was connected in the socket ..)

In such an arrangement of pass-through sockets, I would not like to lose power on the contacts (the wires are 3x2.5 - if I connect to the socket contacts, then going through the next sockets will not be a big loss - the wire contact on the screws is not too large - if any wire is loosened, it can heat up. on the contacts - it is not even known in which socket ...)

It is about pass-through sockets - on one side there are 3 power cords - on the other side there are 3 wires for the next socket. How to connect them to the socket and let the electricity go on (connect 2 wires on the screws in the socket, are there any cubes or other way ...)

So far, I have always dealt with installations that the main box was above the socket under the ceiling, from where the electricity went on and one wire for each connection was connected in the socket ..)

In such an arrangement of pass-through sockets, I would not like to lose power on the contacts (the wires are 3x2.5 - if I connect to the socket contacts, then going through the next sockets will not be a big loss - the wire contact on the screws is not too large - if any wire is loosened, it can heat up. on the contacts - it is not even known in which socket ...)