Hello,

I was reading the whole conversation because I have a problem with the esc 950 too.

The motor isn't doing anything, I can try up / down with the keys or programming mode or the wireless transmitter nothing happens.

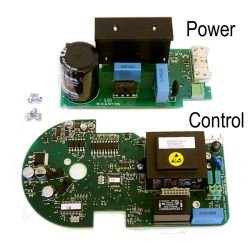

After following the troubleshooting guide I'm pretty sure that there is a problem with the 24V AC and DC power.

I have 24V AC between x1:6 and x1:7, but only 15V AC between x1:7 and x1:9. The guide says replace the manouvring card which makes no sense because the power comes from the motor....

And the second problem is that I have no 24V between x1:7 and x1:5, so the security receiver from the bottom lip has no power which results in an E04...

Has anybody an idea?

Best regards

I was reading the whole conversation because I have a problem with the esc 950 too.

The motor isn't doing anything, I can try up / down with the keys or programming mode or the wireless transmitter nothing happens.

After following the troubleshooting guide I'm pretty sure that there is a problem with the 24V AC and DC power.

I have 24V AC between x1:6 and x1:7, but only 15V AC between x1:7 and x1:9. The guide says replace the manouvring card which makes no sense because the power comes from the motor....

And the second problem is that I have no 24V between x1:7 and x1:5, so the security receiver from the bottom lip has no power which results in an E04...

Has anybody an idea?

Best regards