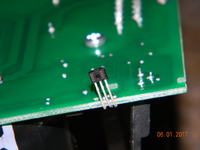

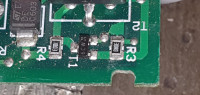

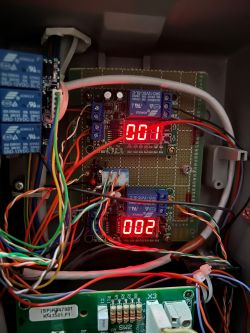

I will refresh the topic ECS930A CDM9 driver, 3 plates in the cheesecake + 2 in the engine, the drive does not move in any way after pressing the up / down button there is no reaction on the plates, after switching on the power supply on plate No. 1 two red RXD and TXD LEDs are blinking relatively steadily , adjusting the potentiometers T1 and T2 to a minimum does not help (they are responsible for the time of auto closing and lighting of the lamp), on board No. 3 after shorting contacts 12-13 to x1, two yellow LEDs from the crimp strip sensor light up, after switching SW1 on it lights up red diode, but pressing the bottom button and the crimp bar does not start the engine, I assume that the motor should have an additional switch on the rotation of the clutch lock, but I cannot remove the inverter plate. I also assumed that on board No. 2 on connector X13 should be shorted 1-3 (anyway, opening does not help) is responsible for blocking the opening. in the 4th picture everything is connected, instead of a pressure sensor I connected an ordinary switch.