FAQ

TL;DR: Measured 12 A at 12 V (~150 W, 25 % above spec) [Elektroda, bestler, post #17239210]; "the device does the job" [Elektroda, bestler, post #17239780] Small 120 W Chinese ZVS heaters can red-heat 6 mm steel in 2 minutes, but lack power for large fast jobs.

Why it matters: Knowing limits, tweaks and safety saves burned MOSFETs and wasted workshop time.

Quick Facts

• Nominal power: 120 W, peak observed: ~150 W @12 V/12 A [Elektroda, bestler, post #17239210]

• Input: 12 V DC (stable supply ≥5 A recommended) [Elektroda, bestler, post #17239780]

• Cost: US $9 ≈ PLN 35 per module [Elektroda, bestler, post #17239210]

• Heating time: 6.5 mm screwdriver to red-hot in 120 s [Elektroda, bestler, post #17239210]

• Curie limit for steel: ~770 °C; visible red ≈ 900 °C [Wikipedia]

What maximum temperature can a 120 W ZVS heater reach?

Steel can be brought to visible red heat (~900 °C), limited by the Curie point (~770 °C) where heating slows [Wikipedia; Elektrode, vodiczka, #17240393]. Small samples reach that in 2–3 minutes; larger masses plateau lower because of heat loss [Elektroda, bestler, post #17239210]

Does the metal type change achievable temperature?

Yes. Ferromagnetic steels heat fastest until the Curie point; non-magnetic metals rely solely on eddy-current losses. Aluminium hardly heats unless placed in a crucible, while copper needs higher power density [Elektroda, CMS, post #17242838]

Is temperature adjustable on these modules?

No built-in control exists; output follows input voltage and load coupling [Elektroda, domel1, post #17239324] Add external PWM or a DC bench supply with current limit for basic regulation.

Can MOSFETs be upgraded safely?

Yes. Replacing the tiny originals with 50 A IRFR2905 improved reliability [Elektroda, bestler, post #17239210] Edge-case: BUZ11 also works but runs hotter [Elektroda, kudlatyco2, post #18671069]

Will IGBT transistors drop in?

Unlikely. IGBTs switch slower than MOSFETs; they may not handle the 100–200 kHz ZVS frequency and will overheat [Elektroda, bestler, post #17241256]

What happens when components fail?

The most common failure is MOSFET short-through causing smoke and PCB burn marks [Elektroda, bestler, post #17239210] Cheap film capacitors can also overheat; WIMA MKP10 rated for high ripple lasts longer [Elektroda, Arek_v1, post #17244104]

How much RF interference does the heater create?

Users report noticeable noise; automatic PSU relays chattered and FM reception degraded within 1 m [Elektroda, bestler, #17239210; TechEkspert, #17241205]. Shielded leads and ferrite beads help.

Do FM radios and phones still work nearby?

FM sensitivity drops, but a mobile phone kept service at 2 m in informal tests [Elektroda, bestler, post #17241505] Results vary with coil size and housing.

Can the coil be shortened to boost efficiency?

Yes—fewer turns reduce inductance, raising resonance. Match it with the capacitor bank to stay in the 100–200 kHz sweet spot for steel [Elektroda, bestler, post #17241256]

May I use a UPS transformer instead of the twin chokes?

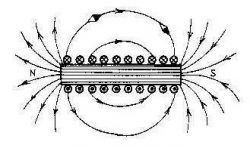

No. The two toroidal chokes must not be magnetically coupled; a transformer would saturate and kill ZVS action [Elektroda, lazor, post #17251861]

What power supply works best?

Server SMPS bricks (12 V / 60–100 A) cost little and handle surge current better than variable bench PSUs that may trip [Elektroda, robokop, post #17239849]

How fast can larger modules heat metal?

A 1000 W kit can red-heat an 8 mm Allen key in 30 s, over four times faster than the 120 W board [Elektroda, nici, post #17240223] "Higher power widens possibilities" [Elektroda, robokop, post #17239723]

3-step: Replacing burnt MOSFETs

- Desolder damaged transistors and clean pads.

- Fit low-Rds(on) TO-251/TO-220 MOSFETs rated ≥50 A, 40 V.

- Add a small heat-sink and test at 5 A before full power.

Any safety tips for workshop use?

Keep coil insulated; hot metal can spit. Use eye protection, ventilate fumes, and avoid placing bank cards or watches within 20 cm due to strong magnetic fields.