Rotary encoder - pulser - is an excellent input device for controlling e.g. menus in the device interface. In the following tutorial, we will describe how to use a typical pulser in conjunction with the Arduino module.

Step 1. Watch the movie

If you do not want to read the entire text below, and the English language is not a problem for you, watch the video below - it will certainly help you understand how to connect the pulser and program the Arduino so that the whole thing works together.

Step 2. Introduction

Such an encoder is an electromechanical device that translates the angular position or rotation of an axis into a digital or analog output signal. There are two types of rotary encoders:

1) Absolute - The output state of this encoder corresponds exactly to the absolute position of the axis. Thus it is an angle converter.

2) Incremental - the signals at the output of this encoder correspond to the axis movements, so the position calculated on their basis is relative. Processing these signals into data on position, rotational speed, etc. is always carried out remotely.

Step 3. What is an incremental rotary encoder

The incremental encoder gives information about changing the position and its direction (clockwise and counterclockwise rotation). In many applications this functionality is essential, however, this element does not track the absolute position. Therefore, in some encoder applications, it may be necessary to initialize the encoder by moving it to a known, fixed position.

Step 4. Construction and principle of operation

An exemplary encoder that we will use in the tutorial has all the necessary resistors that pull the I / O lines. This element has five output pins:

Clock, Data, Switch, Vcc, GND.

Construction

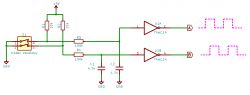

The knob we turn is internally connected to the disk inside the encoder. It will move clockwise or counterclockwise, just like the knob that the user turns. On the surface of this disk there are fields connected to the power line. The remainder of the disk is at ground potential. Above the disk there are two contacts shifted relative to each other by a certain distance - these are the outputs of the Clock and Data.

Principle of operation

When we turn the encoder, the state of the outputs will change with the position of the disk in the encoder. In such a situation, we can observe sequences of impulses on the Clock and Data outputs.

If we look at these impulses, we can see that they are out of phase by 90 degrees. If the encoder turns clockwise, the clock output pulses will be first, and if the encoder turns counter-clockwise, the first pulse will be shown at the data output.

By analyzing the state change on these two outputs, you can immediately judge which direction the encoder knob is turning. Now let's try to implement this analysis programmatically in Arduino.

Step 5. Software

Example 1: (Counter.ino)

In this example the clock pin is connected to pin 3 and the data pin is connected to pin 4. We have connected a switch to pin 5 which activates when we press the encoder.

In the above program, we first defined a series of variables and set the pins to which the encoder was connected as input pins. Finally, a serial port was launched, which we will use for communication and data transmission.

Then the main program loop is started. This is where we read the state of the encoder inputs. The current state is written to the variable state. If state! = State in any iteration, it means the encoder has turned. Then if data! = State it means the encoder turned clockwise and vice versa if the variables are equal. These encoder pulses will increment and decrement the counter accordingly.

The current counter value is then transferred via the serial interface. If the button is pressed, the counter will be reset and the new value will also be sent via the serial port.

At the end of the loop, the new state is written to the variable state and the cycle can start all over again.

Example 2: (LEDBrightness.ino)

In this case, being a modification of the first program, the counter value is used to control the brightness of the LED via PWM. The counter value is directed to the analogWrite function instead of the UART interface. You should only limit the value of the counter to a value from 0 to 255, because such values are taken by the variable controlling the PWM filling.

And that's all you need to easily handle the rotary encoder - the pulser in our device. Do you use such an element in your projects? Show off your implementations and devices, not necessarily based on Arduino modules.

Source: https://www.instructables.com/id/How-to-Use-an-Rotary-Encoder-With-Arduino/

Step 1. Watch the movie

If you do not want to read the entire text below, and the English language is not a problem for you, watch the video below - it will certainly help you understand how to connect the pulser and program the Arduino so that the whole thing works together.

Step 2. Introduction

Such an encoder is an electromechanical device that translates the angular position or rotation of an axis into a digital or analog output signal. There are two types of rotary encoders:

1) Absolute - The output state of this encoder corresponds exactly to the absolute position of the axis. Thus it is an angle converter.

2) Incremental - the signals at the output of this encoder correspond to the axis movements, so the position calculated on their basis is relative. Processing these signals into data on position, rotational speed, etc. is always carried out remotely.

Step 3. What is an incremental rotary encoder

The incremental encoder gives information about changing the position and its direction (clockwise and counterclockwise rotation). In many applications this functionality is essential, however, this element does not track the absolute position. Therefore, in some encoder applications, it may be necessary to initialize the encoder by moving it to a known, fixed position.

Step 4. Construction and principle of operation

An exemplary encoder that we will use in the tutorial has all the necessary resistors that pull the I / O lines. This element has five output pins:

Clock, Data, Switch, Vcc, GND.

Construction

The knob we turn is internally connected to the disk inside the encoder. It will move clockwise or counterclockwise, just like the knob that the user turns. On the surface of this disk there are fields connected to the power line. The remainder of the disk is at ground potential. Above the disk there are two contacts shifted relative to each other by a certain distance - these are the outputs of the Clock and Data.

Principle of operation

When we turn the encoder, the state of the outputs will change with the position of the disk in the encoder. In such a situation, we can observe sequences of impulses on the Clock and Data outputs.

If we look at these impulses, we can see that they are out of phase by 90 degrees. If the encoder turns clockwise, the clock output pulses will be first, and if the encoder turns counter-clockwise, the first pulse will be shown at the data output.

By analyzing the state change on these two outputs, you can immediately judge which direction the encoder knob is turning. Now let's try to implement this analysis programmatically in Arduino.

Step 5. Software

Example 1: (Counter.ino)

Code: C / C++

In this example the clock pin is connected to pin 3 and the data pin is connected to pin 4. We have connected a switch to pin 5 which activates when we press the encoder.

In the above program, we first defined a series of variables and set the pins to which the encoder was connected as input pins. Finally, a serial port was launched, which we will use for communication and data transmission.

Then the main program loop is started. This is where we read the state of the encoder inputs. The current state is written to the variable state. If state! = State in any iteration, it means the encoder has turned. Then if data! = State it means the encoder turned clockwise and vice versa if the variables are equal. These encoder pulses will increment and decrement the counter accordingly.

The current counter value is then transferred via the serial interface. If the button is pressed, the counter will be reset and the new value will also be sent via the serial port.

At the end of the loop, the new state is written to the variable state and the cycle can start all over again.

Example 2: (LEDBrightness.ino)

Code: C / C++

In this case, being a modification of the first program, the counter value is used to control the brightness of the LED via PWM. The counter value is directed to the analogWrite function instead of the UART interface. You should only limit the value of the counter to a value from 0 to 255, because such values are taken by the variable controlling the PWM filling.

And that's all you need to easily handle the rotary encoder - the pulser in our device. Do you use such an element in your projects? Show off your implementations and devices, not necessarily based on Arduino modules.

Source: https://www.instructables.com/id/How-to-Use-an-Rotary-Encoder-With-Arduino/

Cool? Ranking DIY