janjjw wrote: ....

one simple conclusion follows from what you write:

a 3D printer is just a toy with severely limited utility. The design I have drawn is a few simple solids. That's as much as I can do for now. You have proven, beyond a shadow of a doubt, that printing it makes no sense. Since the device cannot print something so simple with reasonable accuracy and in a reasonable amount of time, it is just a toy.

I have to disagree with this statement very much.

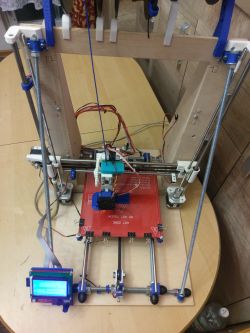

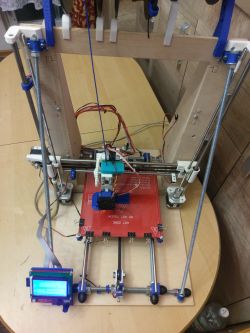

About 1/2 a year ago I built myself a "3D printer".

This forced me to familiarise myself with CAD software.

I cannot call devices of this type toys.

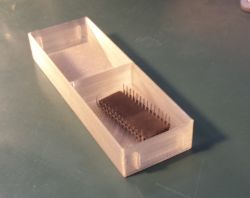

You can really "conjure up" a lot of useful things with them.

As far as cost-effectiveness is concerned.

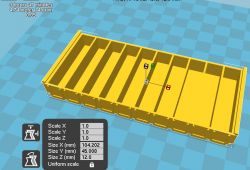

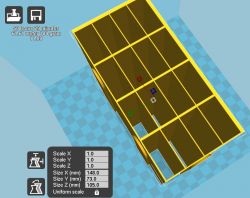

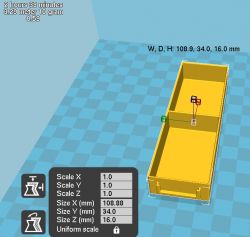

Hmm. I agree with the previous speakers. Many items, such as the parts tray presented, are expensive to make relative to the masses.

But it was (will be) made for the author of the project.

Many items, devices in the DIY section are form over substance and are expensive to make, however, is that the point ....

In conclusion, in my opinion, the 3D printer is most suitable for producing prototypes, single copies, something unique.