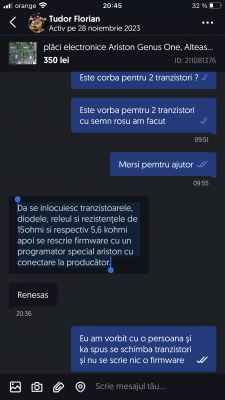

Hi guys. I have read the entire branch of this problem. I have a problem with the boiler for the second time, 1.5 years ago I replaced the board, but after a year and a half the problem appeared with a new board. I didn't want to buy the board for the second time and decided to find the reason. Ariston Russia also could not solve the problem and could only offer to replace the board with a new one, and the warranty period has already passed. Therefore, I did not want to pay for a new fee a second time.

After reading all the tips and recommendations, I did the following.

1) replaced the ceramic SMD capacitor with a disk ceramic capacitor instead of 1nF put 22nF.

2) replaced 4 SMD resistors with metal resistors with the ability to allocate 1-2 watts of heat, I left the same ratings that were on the board 1 resistor at 10 ohms, 2 resistors at 15 ohms and 1 resistor at 5.6 ohms. These 4 resistors are very hot and they should be replaced in principle, it is also not necessary to solder the SMD options - they heat the board in the places of soldering during the operation of the gas relay.

3) I glued aluminum radiators on the LM317M and two adjacent bipolar transistors BCP53-16 to the thermally conductive glue. As the gas relay turns on, these parts get very hot more than 60 degrees Celsius, and I think if they work in this mode for several years with a closed case and a boiler lid, they become unusable when heated.

4) I also soldered 3 chips processor, memory and something else, just to dispel assumptions about cold contact.

5) I also hung a ferrite filter on the wiring of the gas relay (I don't know if it helped, but it definitely didn't get worse).

The conclusion of these actions was the following: at first the board did not want to start, but it turned out that it was necessary to clean it from traces of soldering and soldering flux. Errors 5P3/5P6/501 have stopped appearing altogether. It turned out to finish the calibration of the burner by opening 2 or more hot taps at the time of calibration of the burner (in order to remove the generated heat). Previously, I often had these errors of ignition and flame extinguishing. The whole problem is in the board, no mechanical influences will lead to a solution to the problem. Try to do the same as me, I think I have found a solution to the problems with this board by removing the overheating of the chips and parts, as well as replacing the resistors and capacitor with unused and not overheating earlier. By the way, I first put the capacitor on 1nF, but this was not enough and errors still did not appear so often, but still did not completely go away. So put the capacitor on 22nF, the board works with it, and also I don't get an error with it about checking the gas relay.

After completing all the actions, I went to menu 234, then selected item 280 and reset the boiler settings to factory settings and started the automatic calibration function of the boiler.

Also, the boiler stopped making pops at the moment of ignition of the flame, previously there were very bad and loud pops.