Hello.

Today I'm going to show a short, emergency 3D print that might come in handy for someone - a "triangle" key for KS-17 security padlocks fitted to electrical boxes, for example. The key itself is readily available for a few zlotys, but what can you do when it's Sunday, the shops are far away and you need to open a box in an emergency? That's what you can do - you can use a 3D printer.

The situation was such that one of the padlocks wouldn't open with 'guerrilla' methods, and the other wasn't locked anyway, so I had a disassembled padlock as a model:

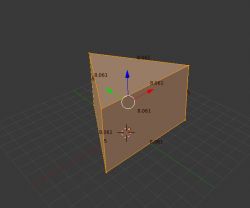

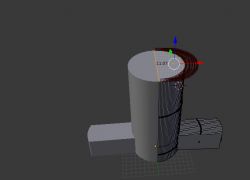

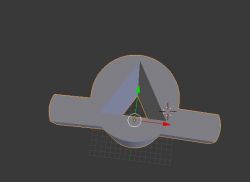

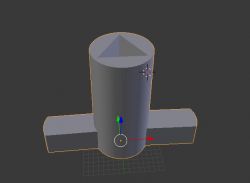

In Blender, I started with the shape of the triangle and its dimensions:

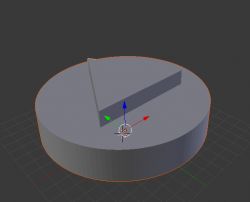

I then used it to cut a hole in the circle, boolean subtract:

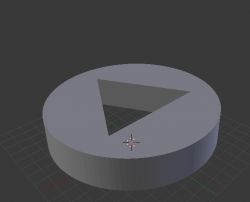

At this stage I have made a few prints for the fitting, as a trial:

Successful fitting:

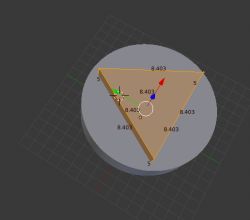

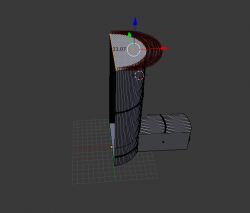

The next step was to give the project real depth:

I helped myself with the mirror tool. The triangle shape is cut out, so there are no problems with the supports and it saves a bit of material:

Finished print:

Fitment:

Weight and printing time with Cura:

Two grams and 20 minutes! That's very little indeed.

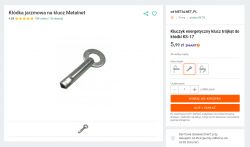

Still to be seen - identical keys on a Polish auction site:

So buying this key would cost me about £6, plus shipping costs (of £9?), and let's not forget the waiting time.

Summary

I would rather not normally print this, but an emergency situation forced me to do so and fortunately it went off without a hitch. Was it worth it? For the sake of time, yes; but even so, you have to admit that such a key itself is quite cheap, although the lack of a good stationary shop nearby also complicates things a bit, because then you have to add shipping as well. My printed key costs only as much as some two grams of filament , that is, with the price of 50 PLN per kilogram it is pennies, even if you add the electricity/maintenance of the printer, it still remains pennies.... I'm not counting design time (playtime) here.

Maybe this will be useful to someone - I've put the downloads below.

Do you have any other similar print ideas or experiences where the printer saved the situation and allowed to produce a sufficiently durable equivalent of some popular tool?

Cool? Ranking DIY Helpful post? Buy me a coffee.