FAQ

TL;DR: To view IC supply current up to 1 GHz, use a low‑inductance shunt plus a 50 Ω readout; “Low inductance is key” [Elektroda, Anonymous, post #21621246] Regulatory scans span 150 kHz–1 GHz [Elektroda, Anonymous, post #21621244] Tektronix CT1/CT6 reach 1 GHz [Elektroda, Anonymous, post #21621242]

Why it matters: This helps hardware engineers diagnose EMI by revealing the real current spectrum without corrupting the circuit.

- Regulatory EMI scan band: 150 kHz–1 GHz (radiated/emissions context) [Elektroda, Anonymous, post #21621244]

- Tektronix CT1: 1 GHz, 450 mA rms, approx. $635 (off‑the‑shelf probe) [Elektroda, Anonymous, post #21621242]

- Tektronix CT2: 200 MHz, 2.5 A rms, approx. $618 [Elektroda, Anonymous, post #21621242]

- Tektronix CT6: 1 GHz, 120 mA rms, approx. $664 [Elektroda, Anonymous, post #21621242]

- Sense‑resistor readout: shunt to SMA via 50 Ω; scope input 50 Ω → 25 Ω Thevenin for compensation [Elektroda, Anonymous, post #21621248]

Quick Facts

- Target use: Engineers needing 100 MHz–1 GHz current visibility for IC power pins [Elektroda, Anonymous, #21621241; #21621244].

- Non‑invasive probes exist, but inline inductance can corrupt IC behavior at GHz speeds [Elektroda, Anonymous, post #21621246]

- Low‑impedance interconnect is critical; a 1 Ω “transmission line” can be ~50× wider than a 50 Ω line (approx.) [Elektroda, Anonymous, post #21621248]

- Compensation: Shunt inductance zero can be flattened with a pole from a shunt C and 25 Ω source [Elektroda, Anonymous, post #21621248]

- Budget: $600–$700 class current probes cover 200 MHz–1 GHz if inline probing is acceptable [Elektroda, Anonymous, post #21621242]

What’s the most reliable way to measure high‑bandwidth IC supply current (100 MHz–1 GHz)?

Use a very low‑inductance current viewing resistor placed close to the IC, then route through a 50 Ω series resistor to a 50 Ω scope or analyzer. Avoid adding probe inductance in the power path. “Low inductance is key” for valid results [Elektroda, Anonymous, #21621246; #21621248].

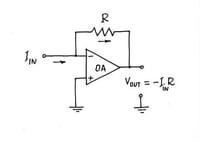

High‑side shunt vs transimpedance amplifier: which is better above 100 MHz?

A high‑current, low‑L shunt with 50 Ω readout is more practical. A high‑speed, high‑current TIA is possible but is a greater challenge to implement cleanly at these frequencies [Elektroda, Anonymous, post #21621250] Difference‑amp ICs compensated for sub‑unity gain exist, but parts found were too slow for 100 MHz+ in this context [Elektroda, Anonymous, post #21621249]

How do I build a low‑inductance current viewing resistor (CVR)?

Parallel small resistors on the PCB to make ~1 Ω, placed very close to the IC’s power pins. Connect the shunt to the IC via a very short, very low‑Z trace (the “1 Ω” line). Measure at an SMA through 50 Ω [Elektroda, Anonymous, #21621246; #21621248].

How‑To:

- Parallel 10 Ω parts to form ~1 Ω right at the IC pad [Elektroda, Anonymous, post #21621246]

- Route a very short, ultra‑wide “1 Ω” line to the pin(s) [Elektroda, Anonymous, post #21621248]

- Feed SMA via 50 Ω to a 50 Ω input [Elektroda, Anonymous, post #21621248]

How do I read the shunt voltage without loading it or adding peaking?

Connect the shunt to an SMA through a 50 Ω resistor and terminate into a 50 Ω scope. The source looks like 25 Ω Thevenin. Compensate the shunt’s inductive zero by adding a shunt capacitor at the SMA to place a complementary pole with that 25 Ω [Elektroda, Anonymous, post #21621248]

How wide is a 1 Ω transmission line on FR‑4?

Approximate rule: a 1 Ω stripline can be ~50× the width of a 50 Ω line. Since a 50 Ω stripline width is about 2× the dielectric spacing, the 1 Ω width is about 100× the spacing. Use EM tools (e.g., SONNET LITE) for exact geometry [Elektroda, Anonymous, post #21621248]

Why not just clip on a Tektronix CT1/CT2/CT6 current probe?

Inline current probes add too much series inductance in this specific high‑speed supply path. That disturbs the IC and corrupts the measurement. Use a low‑L CVR instead [Elektroda, Anonymous, post #21621246] If you must use off‑the‑shelf probes, note CT1/CT6 are 1 GHz and CT2 is 200 MHz, with the listed current limits and prices [Elektroda, Anonymous, post #21621242]

How do I tie current spectral content to EMI failures?

Measure current from 150 kHz to 1 GHz to match regulatory scans, then fix layout to shrink HF current loops. Add tight local decoupling, create local power/ground nets under the IC, and connect to the main planes at a single, close point with a larger second‑tier cap [Elektroda, Anonymous, #21621244; #21621245].

Can I put the shunt in the ground return instead of high‑side?

Yes. The circuit does not need to be high‑side for this diagnostic. Placing the CVR in the ground pin return is acceptable when you only need a spectrum view and can tolerate small impedance [Elektroda, Anonymous, post #21621244]

Are difference‑amplifier ICs viable at 100 MHz+?

Difference amplifiers are op‑amps compensated for <1 gain and can offer higher bandwidth. However, parts checked were too slow for this 100 MHz+ requirement. Building your own sub‑unity gain stage risks instability [Elektroda, Anonymous, post #21621249]

How do I flatten the response of a slightly inductive shunt?

Model the shunt’s inductance as a zero. Add a capacitor at the SMA to create a pole with the 25 Ω source (50 Ω series into 50 Ω input). Tune C so the pole cancels the zero over your band [Elektroda, Anonymous, post #21621248]

What shunt value should I use for high‑current devices like DRAM?

Use a lower value, e.g., ~0.1 Ω, to keep voltage drop and disturbance small while preserving bandwidth. Keep interconnects ultra‑low inductance and very short to avoid corrupting the real‑time current profile [Elektroda, Anonymous, post #21621248]

How do I feed a spectrum analyzer with this current measurement?

Convert current to voltage with the CVR, then drive the analyzer’s 50 Ω input through a 50 Ω series resistor. This preserves a controlled source and allows response shaping via a shunt capacitor if needed [Elektroda, Anonymous, #21621248; #21621244].

What layout practices reduce the emissions I’m seeing in the current spectrum?

Minimize loop area. Add tight local bypass between the IC’s local power and ground nets. Route crystal caps to the local ground, not the plane. Connect local nets to main planes at one close point with a larger cap across that junction [Elektroda, Anonymous, post #21621245]

Edge case: When will this approach fail or mislead?

If the CVR or interconnect adds too much inductance or capacitance, the IC’s operation and measured spectrum change. Also, placing a current probe like a CT‑1 directly in the supply path adds excess inductance and corrupts results [Elektroda, Anonymous, #21621246; #21621248].

Can I just sniff with a small loop to see if the board radiates?

Yes. Make a small loop antenna and scan with your spectrum analyzer to localize hot spots. This is quick for triage but does not measure supply current directly [Elektroda, Anonymous, post #21621252]

How about designing an AC clamp current meter that logs to a microcontroller?

For high‑speed IC current, do not use a current‑viewing transformer; it disturbs the path [Elektroda, Anonymous, post #21621250] For mains AC analysis, a clamp CT feeding a burden resistor and ADC is typical. Ensure proper isolation and scaling before the MCU. This is separate from the GHz IC‑supply problem [Elektroda, Anonymous, post #21621250]