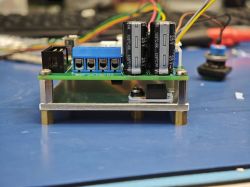

On the configuration side, for example, audio is better than Volumio. We'll see, maybe in time the priorities will change and one of the players will be on Moode.

Czy wolisz polską wersję strony elektroda?

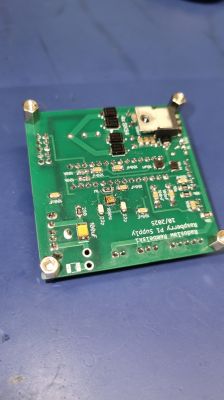

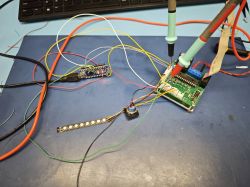

Nie, dziękuję Przekieruj mnie tamtytka wrote:I found it simpler to check 5V on the USB than to add extra functions.

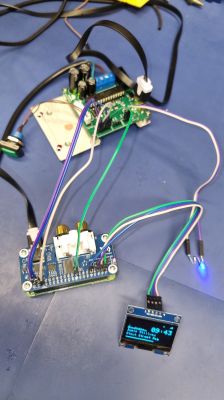

There's a 4.3" screen on what I've shown. But I have a 7" too, maybe there will be another version with it.