In Polish measurement equipment it is common to find filters manufactured by Silesia . The diagram on the chassis allows discussion of each part of this filter - the purpose of the choke at the input is to suppress common mode interference ( common-mode interference ), that is, interference that occurs simultaneously on the L and N wires relative to PE. Two capacitors of type Y form a low impedance path to earth for high frequency currents. The capacitor type X is intended to suppress differential interference ( differential-mode ), i.e. that which occurs between the L and N conductors. It acts as a shunt for high-frequency currents, allowing them to flow past the receiver (the rest of the device).

What are the problems with them?

These filters were built using paper capacitors. The filter housing was filled with tar and the whole thing was sealed with epoxy resin. After years, this resin often cracks and moisture gets inside. The capacitors get leakage, so several things can happen. It usually ended up that when plugged in, the filter explodes with a big bang or slowly expands, pelting the inside of the unit with tar. The repair is to remove the filter, which can be replaced with a modern factory design made with film capacitors, or it can simply be cut out, reckoning with a higher level of interference. The tar can be easily removed with either extraction petrol or WD-40.

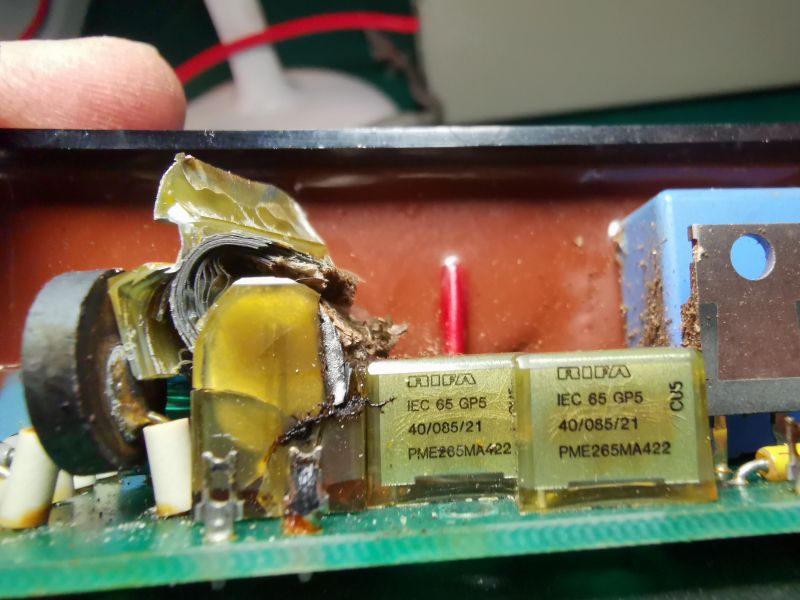

The story is very similar with RIFA capacitors.

Some say that Surstromming is the worst thing the Swedes have given the world, but my poll winner is these paper capacitors. The EEV Blog forum community often jokes that an extension of the name RIFA is " replace if found, always! " The capacitor housing is simply a layer of resin that cracks after years and leakage occurs. I have repaired quite a lot of Tektronix brand measuring equipment by simply replacing the RIFs with good quality polypropylene capacitors WIMA or Wurth Electronics .

The problem is not Tektronix's domain - in HP digital oscilloscopes from the 1990s, such capacitors sat in filters integrated into the socket and switch. Worst case - it's hard to get such a filter for anything.

Cool? Ranking DIY