Here I will present the WEP 8858 portable hot air, also often advertised as a 'plastic welder' or as a '100-650W digital soldering station'. I will check how it handles the soldering of components from the motherboard and then try to measure its power consumption and the temperature reached and show this in the form of accessible graphs. I will do the tests for temperatures of 100 °C, 350 °C and 450 °C.

The WEP 8858 can be imported from China for even less than 100 PLN. In our country it will be a bit more expensive, I have even seen prices double.

Set contents

My copy is marked 8858-I - Portable SMD Rework Station. The information on the packaging does not suggest a 'plastic welder', but straightforward work in electronics with SMD components.

The unit is quite well protected for transport. In addition to the hot air itself, we get three nozzles - a 12mm x 12mm square one and 9mm and 7mm round ones. A stand is also included.

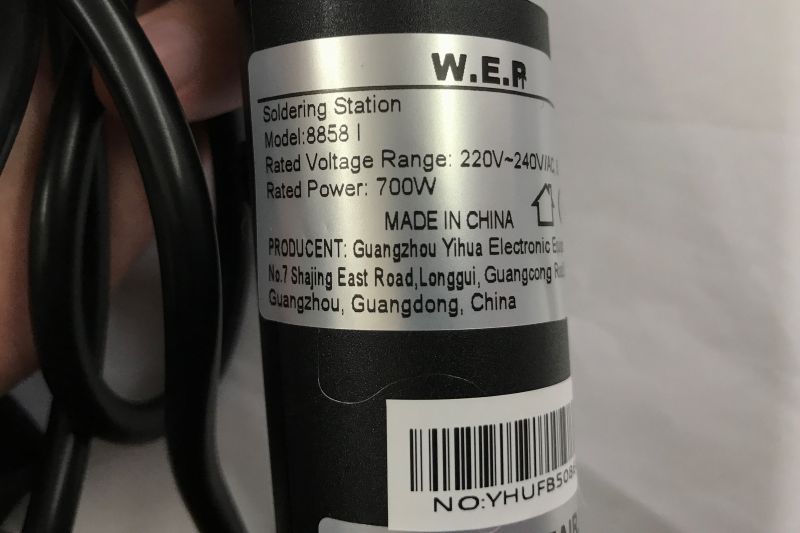

Nameplate:

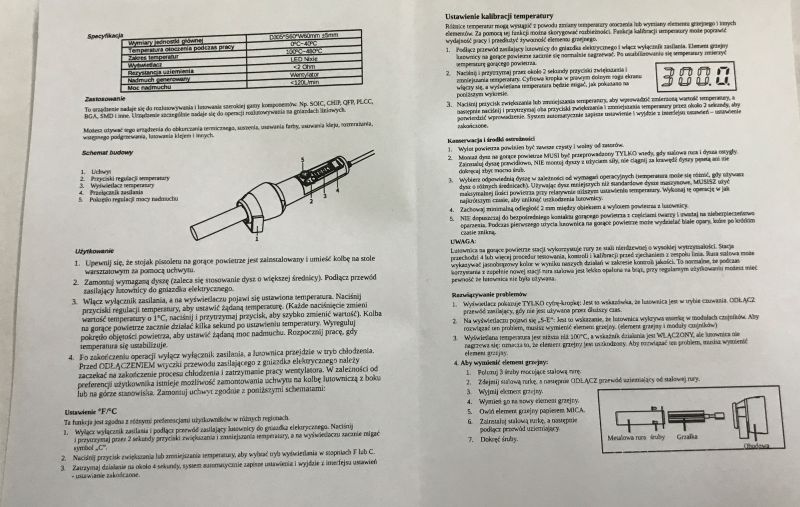

The Polish-language manual mentions, among other things, calibration and replacement of the heating element. It is good that this has been provided for. I do not recommend buying disposable products.

One line from the specification, however, puzzles me. Does this station really have an "LED Nixie" display? Unless they mean "Nixie styled LED display" here.

Tests with motherboard

The whole thing is simple and convenient to use. The blower is adjusted with a potentiometer, the temperature with buttons. When you have finished working, you do not disconnect the whole thing from the mains, because the station first still cools itself by blowing air without heating, as per the instructions.

You can confidently test. Just on what? I have chosen a large PCB:

The more copper, the more massive the board, and the more layers, the harder it is to solder the component.

A motherboard from a computer would probably be even better, but I didn't have any on hand.

First test - 300 °C, full blast.

I gave up after 5 minutes. It was not possible to solder the component.

I increased the temperature to 450 °C:

The component came off after 2 and a half minutes. No revelation.

Second test - 400 °C:

Here I helped myself with flux, an element in an enclosure such as a flash memory chip came off in two minutes. This means that, if anything, it would be possible to upload firmware in case the clip from the CH341 fails. The minimum functionality is.

Third test - 400 °C:

Next something more difficult, a coil from one of the inverters. Such a component is quite large and sits on a larger copper spout, which acts as a heat sink and absorbs heat.

I heated for three and a half minutes, but the element was able to be removed.

Fourth test - 450 °C:

This time the coil came off in one and a half minutes.

Fifth test - 450 °C:

A tiny component in a QFN housing.

The situation is difficult because the component is also soldered underneath. It was successful in one and a half minutes.

Sixth test - 450 °C:

A slightly larger component. Also with a mass underneath. This can be seen when it is pulled off.

Just under two minutes.

Seventh test - 450 °C - no nozzle, larger QFN component.

Two minutes.

Conclusions a little further on.

Temperature measurements

I made the measurements based on the configuration from this topic:

OpenBeken configuration for hot air testing - MAX6675, temperature and power logging

Measurements were taken at full blow and at 50% blow.

Here I have prepared two sets of measurements:

- measurements only for WEP 8858, at three temperatures, I also checked the different levels of blowing

- a summary comparison of all the stations I have had so far

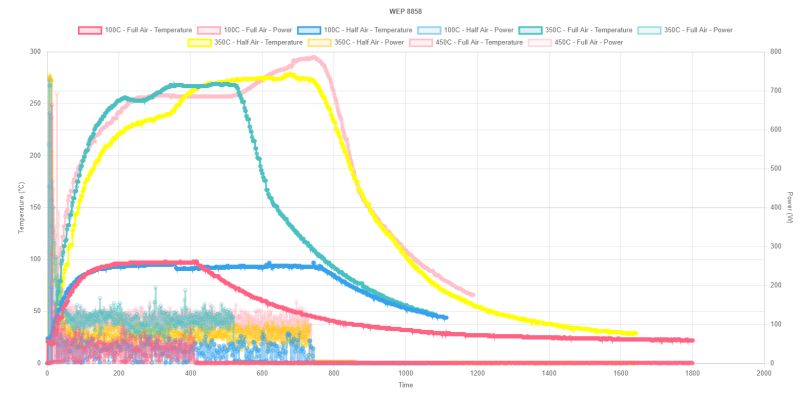

Let's start with the measurements of the 8858 only.

Interactive version: https://openshwprojects.github.io/hotairwep8858.html

The first thing that strikes me is the small difference between heating at 350 °C and 450 °C. The curves intersect there, but it's all within error. It seems that the 450 °C setting only approached 300 °C by a 'throw on the belt'. A lower setting, 350 °C, on the probe gave a temperature only about 25 °C lower.

Someone might think that the temperature setting doesn't work at all - but no, you can see from the results with the 100 °C setting that it has some effect after all. At 100 °C, the results are actually very accurate. The full-blow setting achieved some 98 °C, the half-blow setting 90-95 °C, also within the margin of error.

The differences between full blow and half blow are negligible in my sensor tests.

It can be equally interesting to analyse the power consumed. Those promised 700 W are only there at the beginning. Even when heating to 450 °C (which, by the way, is remarkably similar to the 350 °C setting), the power drawn most of the time is around 120 W.

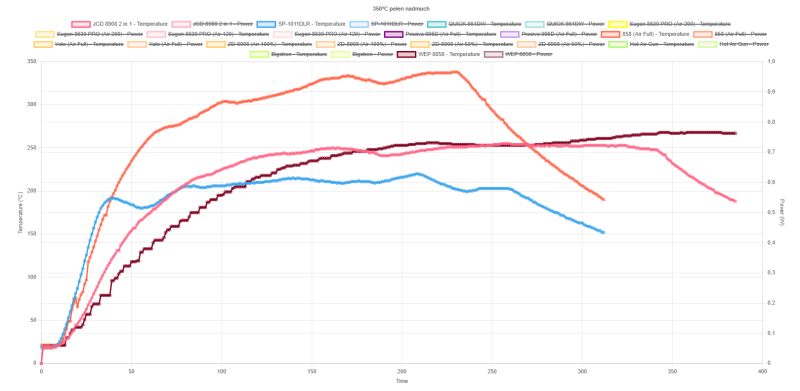

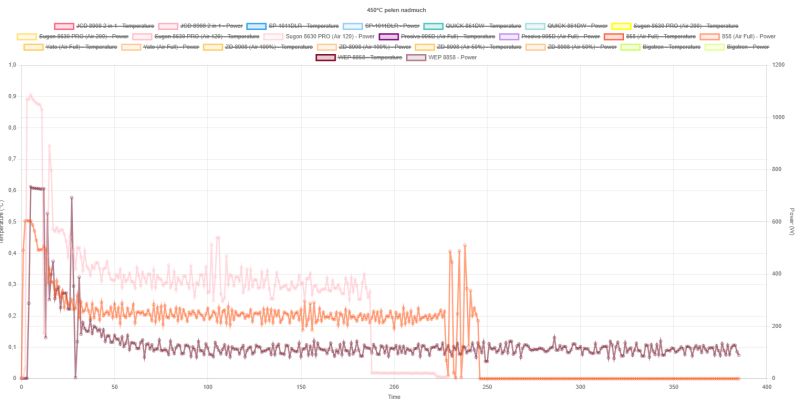

You can now also take a look at the summary graph. It is separately for the two temperatures:

https://openshwprojects.github.io/hotair/version9/450c.html

https://openshwprojects.github.io/hotair/version9/350c.html

Not a revelation, the performance of this station is similar to the weaker ones I tested, the JCD 8908, SP-1011DLR, etc. Even the budget and classic 858 trumps it.

Out of curiosity I included three interesting stations on it - the Sugon 8630 PRO (high end, very expensive), the 858 (cheap but good hot air) and the eponymous WEP 8858. You can see by the power alone that there is definitely a heating difference, as it is the power here that translates into heat:

Everyone can also draw their own conclusions from the graphs, so I provide interactive versions for reference:

https://openshwprojects.github.io/hotair/version9/450c.html

https://openshwprojects.github.io/hotair/version9/350c.html

https://openshwprojects.github.io/hotairwep8858.html

Summary

Indeed, this device is able to perform basic operations on the motherboard, you can, for example, solder a flash memory bone or a punctured transistor there, but it is a bit more difficult and slower than the other stations tested. For products from the higher end, such as the Sugon or Quick tested earlier, there is no point in comparing the 8858, but the budget hot air 858, for example, also trumps the product in this topic.

At 100 °C I have no complaints, my thermocouple then recorded 95 °C so literally within the margin of error, perfect, only surprised by the 450 °C setting which doesn't seem much warmer than 350 °C at all.

I also tried to catch the differences between the different blower settings, but my method was unlikely to be precise enough to make anything noticeable.

Do you think the seller is right to offer this gadget as a tool for SMD work, or should he stay with "plastic welder" after all?

Cool? Ranking DIY Helpful post? Buy me a coffee.