As for me - a revelation.

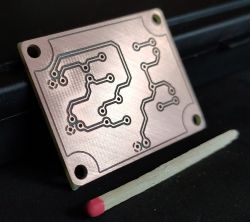

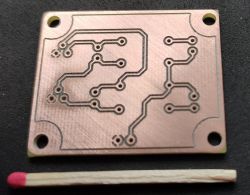

Even for highly hobby applications, such as: 3 PCBs per year. And I don't need 2-3 mils insulation. 12 mils is as much as 0.3 mm.

How would I play with various chemical methods would be:

1. Photochemically - laser printer needed, photosensitive laminate, UV exposure device, exposed laminate development, developer temperature, etching of photosensitive laminate induced, etchant temperature, cuvettes, tongs, gloves, glasses, inhalation of vapors, developer storage, etchant storage.

2. Thermal transfer - laser printer needed, iron (although it can also be transferred without iron, cold), etching of the laminate covered with toner, temperature of the etcher, cuvette, tongs, gloves, glasses, inhalation of vapors, storage of the etchant.

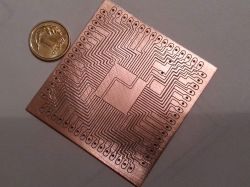

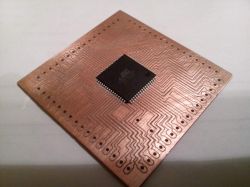

And here we have the physical removal of the copper layer from the ordinary (not any photosensitive) laminate to a depth of about 0.04 mm using CNC milling. You do not need any: laser printers, UV irradiators, cuvettes, tweezers, gloves, glasses. There is no inhalation of any chemical fumes. There is no need to store any hazardous chemical solutions.

It would be enough to:

1. Eagle from pcb-gcode.ulp.

2. Mini CNC milling machine (included in the price of a new monochrome laser printer), such as this:

https://allegro.pl/oferta/cnc3018-pro-grawerka-laserowa-sterowanie-9152266028.

3. Engraving cutter 0.2 mm, for example:

https://allegro.pl/oferta/frez-vhm-grawerski-...QoIPTN50WwNXfsE-O3RVqhCna5g5RVqhCna5g5RVqhCna.

3. 0.9 mm drill bit, for example:

https://allegro.pl/oferta/wiertlo-weglik-widia-do-plytek-pcb-0-9-mm-9505195133.

4. 0.5 mm multi-edge cutter, for example:

https://allegro.pl/oferta/frez-diamentowy-wieloostrzowy-pcb-0-5-x-3-175-x-38-9538600240.

I only design PCBs in Eagle. I fire up pcb-gcode.ulp. I put a piece of laminate on the milling machine, fire the appropriate TAP or CNC files one by one, after milling the paths, I change the 0.2 mm engraving cutter to a 0.9 mm drill, drill holes, change the drill bit to a 0.5 mm cutter, cut (mill) the plate after contour. And already. Clean job. Maybe the only nuisance is milling dust and some noise.

And I have a transfer, laser printers, toners, whether original or substitutes, chalk paper, or for thermal transfer, or slippery from colored newspapers, acetone mixed with isopropanol or in such proportion or other, iron, litter boxes, tongs, glasses, aerators, etchants, UV plateseters, developers, chemical rubbing and inhaling chemicals. A lot of nuisance, and you never know how a plate made with transfer methods will come out.