Hi! Another project for my workshop equipment is MPCNC, i.e. a CNC milling machine printed on a 3D printer, today I will share my humble opinion with you (no time for testing, session at PW  ).

).

I always wanted to be able to precisely cut elements in wood, plexiglass and aluminum. I couldn't afford ready-made milling machines, so I decided to build my own The milling machine elements were printed on the printer which he writes about here: Link

The milling machine elements were printed on the printer which he writes about here: Link

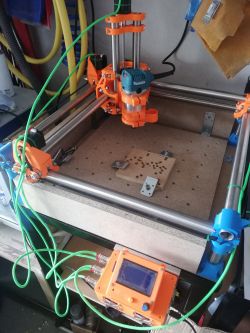

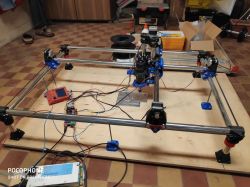

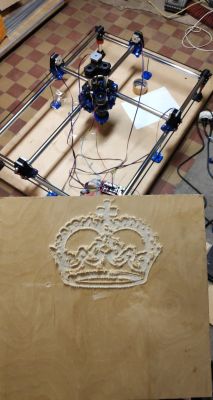

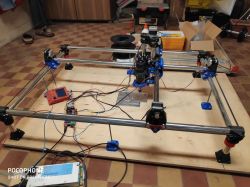

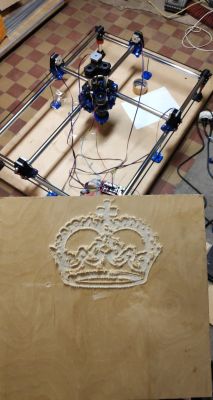

Before further reading I present the still not finished MPCNC:

THE PROJECT IS NOT MINE AND IS GENERALLY AVAILABLE AT THIS LINK: Link

Elements needed for construction:

- PLA 2kg about PLN 120

- 500W air-cooled spindle 350 PLN

- Nema 17 engines 5 pieces PLN 150

- Belts and gears about PLN 20

- Pipes (I had) the approximate cost is about PLN 50 for the pipes that I used

- Bearings, probably 608RS 60 pieces, about PLN 60

- Screws (various types) about PLN 50

- T8 trapezoidal screw about PLN 10

- Flexible coupling to nema 17 about PLN 2

- 12v 500W power supply (I have from old servers from my dad from work)

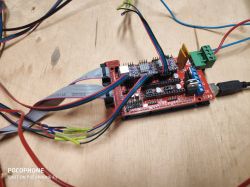

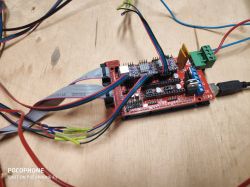

- Ramps 1.4 + Arduino Mega 2560 about PLN 60

- DRV8825 stepper motor drivers 3 pieces about PLN 10

The total cost, not counting the plywood as a table top, is about PLN 900

Before I start talking about whether it is worth mentioning a few more nice and thoughtful aspects of the machine.

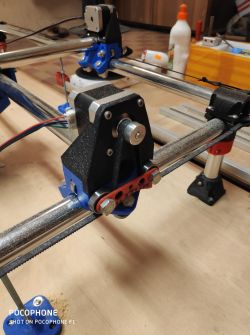

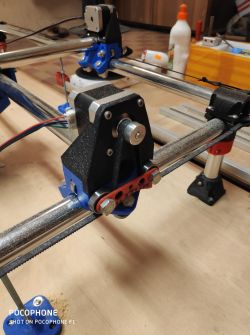

The first thing is fixing the straps on the cable ties, there is no problem with tightening them:

Second thing is nema 17 motors, no need nema 23 because of two motors on X and Y axis.

Easy to use and build for everyone, there are tons of descriptions and tutorials on the internet and some of the works that someone squeezed out of this machine are beyond belief

and some of the works that someone squeezed out of this machine are beyond belief

Due to the large number of guides on how to assemble and configure the machine, I will skip this topic, but I will only mention that there is a modified marlin on the arduino

An important aspect of the machine is that you can theoretically get an unlimited working area, it is enough to buy longer pipes (for me the working area is about 70x50cm) but everyone knows that this is not possible mainly due to the lack of stiffness, so the smaller and lower the better

but everyone knows that this is not possible mainly due to the lack of stiffness, so the smaller and lower the better

No more praising, time for machine trouble. The first main problem is the low stiffness of the original structure, you have to add some improvements here

Another problem is the pace of work, which is mainly due to the rigidity of the machine and the spindle used

Can MPCNC be recommended and is it worth investing?such money into a "toy"? At the moment, it is difficult for me to judge due to the lack of time to test the machine, at the moment it looks promising for amateur and hobby applications

The only test I was able to do was the crown engraving (done with a 6mm cutter, I had no other )

)

I was quite positively surprised that I didn't improve the machine, I just plugged everything in and let the milling go

In my spare time, I start milling aluminum, we'll see how he can handle it

The software I use is AutoCad, NX, Fusion360 and EstlCam.

If I did not write something, please let me know, I will be happy to answer questions and any comments, criticism is welcome

I always wanted to be able to precisely cut elements in wood, plexiglass and aluminum. I couldn't afford ready-made milling machines, so I decided to build my own

Before further reading I present the still not finished MPCNC:

THE PROJECT IS NOT MINE AND IS GENERALLY AVAILABLE AT THIS LINK: Link

Elements needed for construction:

- PLA 2kg about PLN 120

- 500W air-cooled spindle 350 PLN

- Nema 17 engines 5 pieces PLN 150

- Belts and gears about PLN 20

- Pipes (I had) the approximate cost is about PLN 50 for the pipes that I used

- Bearings, probably 608RS 60 pieces, about PLN 60

- Screws (various types) about PLN 50

- T8 trapezoidal screw about PLN 10

- Flexible coupling to nema 17 about PLN 2

- 12v 500W power supply (I have from old servers from my dad from work)

- Ramps 1.4 + Arduino Mega 2560 about PLN 60

- DRV8825 stepper motor drivers 3 pieces about PLN 10

The total cost, not counting the plywood as a table top, is about PLN 900

Before I start talking about whether it is worth mentioning a few more nice and thoughtful aspects of the machine.

The first thing is fixing the straps on the cable ties, there is no problem with tightening them:

Second thing is nema 17 motors, no need nema 23 because of two motors on X and Y axis.

Easy to use and build for everyone, there are tons of descriptions and tutorials on the internet

Due to the large number of guides on how to assemble and configure the machine, I will skip this topic, but I will only mention that there is a modified marlin on the arduino

An important aspect of the machine is that you can theoretically get an unlimited working area, it is enough to buy longer pipes (for me the working area is about 70x50cm)

No more praising, time for machine trouble. The first main problem is the low stiffness of the original structure, you have to add some improvements here

Another problem is the pace of work, which is mainly due to the rigidity of the machine and the spindle used

Can MPCNC be recommended and is it worth investing?such money into a "toy"? At the moment, it is difficult for me to judge due to the lack of time to test the machine, at the moment it looks promising for amateur and hobby applications

The only test I was able to do was the crown engraving (done with a 6mm cutter, I had no other

I was quite positively surprised that I didn't improve the machine, I just plugged everything in and let the milling go

In my spare time, I start milling aluminum, we'll see how he can handle it

The software I use is AutoCad, NX, Fusion360 and EstlCam.

If I did not write something, please let me know, I will be happy to answer questions and any comments, criticism is welcome

Cool? Ranking DIY