Z1mmy wrote: Please have a look at the legend.

Solar Edge Power Optimizers.

The maximum string length is 50 panels or 11250 W per string.

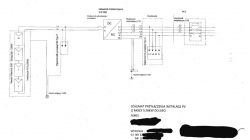

Hello

I design and assemble PV installations

Please be careful with such entries.

1. You cannot turn on 50 panels in one string, unless they have very low voltage

but these are no longer available. Maximum string voltage in Solar Edge 900V

rated 750V for this you need to take the temperature coefficient.

e.g. NU-JB395 Sharp is a maximum of 16 pcs per string in the inverter model, e.g. SE10K we have two inputs, i.e. theoretically we can connect two strings 2x16, the maximum power of modules in this model in STC conditions is 13.5KW these modules have 395W, i.e. together it gives 12.64KW

2. Solar Edge optimizers nice thing, but it costs money. (very good for problems with panel shading)

a properly made installation with another inverter will do the same as without optimizers.

3 As for overcurrent protection on the DC side, no such protection is used for 1 string

please see the parameters of the modules, e.g. NU-JB395 Sharp in the conditions Current intensity at the point of max. power of 9.62A

Closed-circuit current 10.35A

these are not big differences

it is easy to calculate how much more power will be released, but these are conditions that can happen very rarely (it is basically 1-2 days a year in our conditions

The panels work in NMOT conditions longer and then we have such proportions of 7.71A and 8.39A

I apologize for such a long post, it is really worth knowing what the company wants to install so that there will be no problems with such installation

best regards