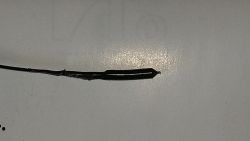

1.75mm filament let loose in a 4mm heatbreak? Brilliant idea... Cool to wrap inside, just a shame you can't see it.

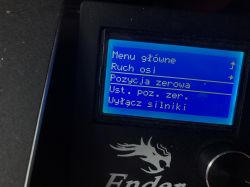

Can't you just leave it as it is and use it like that with the given solution? I've used it, no problems at all with either PLA or PET-G. I must actually have some outstandingly good art.... They did their best at the factory with this one, but how they knew it would go to me is beyond me.

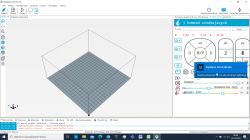

PS. I printed on the factory PET-G hotend at 240 degrees and nothing got damaged, so....

Can't you just leave it as it is and use it like that with the given solution? I've used it, no problems at all with either PLA or PET-G. I must actually have some outstandingly good art.... They did their best at the factory with this one, but how they knew it would go to me is beyond me.

PS. I printed on the factory PET-G hotend at 240 degrees and nothing got damaged, so....