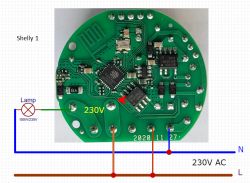

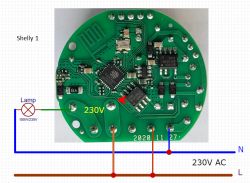

Out of four Shelly 1's two have died. Bought at the turn of the year ie about 5 months old. The first remotely started the blower with a 2kW heater and there was a burnt smell in the can and black smoke at the socket. The second one just stopped working(electronics died).I opened the blue shell with my fingernail and couldn't believe my eyes ....sami see (I drew the connection of the module)

The red arrow shows how much insulation there is between the electronics(ESP8266) and the part of the PCB where the mains voltage is(230V AC).

By eye it is about 0.2mm.This is dangerous. Fear to install Shelly 1 in houses with wooden construction.

Shelly 1 version 3 has a voltage-free output, which means the relay contacts are isolated from the rest of the electronics. This isolation is 0.2mm from 230V circuits .Those who use the module e.g. to open the entrance gate and connect the relay contacts directly to the electronics of the drive can finish the expensive drive.It is better to use the power supply of the drive itself (mostly there is 12 or 24V) .People mostly power the module with 230V and so in the title .... the bomb is ticking and ticking.

.

.

It is also good to compare our Shelly 1 with similar designs e.g. the Sonoff we know.

I have been using SonOffs for many years and even when a lightning strike struck a pole near my house and several pieces of equipment gave up the ghost, all SonOffs survived. I have mixed feelings about Shelly. On the one hand, a great mobile app and on the other hand, the hardware part is dangerous. .

.

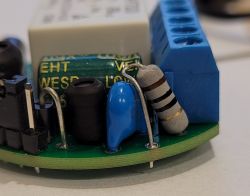

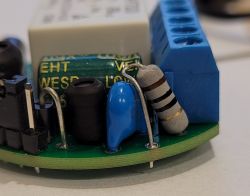

Here the view from the elements. Well, and also uninteresting. The uninsulated leg of the resistor has been clipped onto the adjacent component so that the housing can be closed. The safety hangs on a layer of varnish. The consequence of such a squeeze can be seen here

.

.

Shelly 1 has a 16A relay and a load power of up to 3.5kW.Looking at the PCB we can see the thick tracks connecting the terminal block to the relay.

Here it is asking to whitewash these thick paths with a layer of tin (I crossed the soldering points with millimeter silver) . .

.

At high currents the relay contacts get hot and heats up the solder leg in the PCB.Over time microcracks in the copper layer form around the solder point and arcing occurs. Solid thick tracks flooded with tin, electrical arc quenchers in the form of milled slots can be seen at Sonoff.

.

.

In the photo(from the net) is a Sonoff POW R2 PCB.This module controls two ski boot dryers, each with 1.5kW or a total of 3kW. I was worried whether this module would be able to withstand such power, but it has been in operation for 2 seasons and is OK.

Tin reinforced tracks can also be seen in the module from Pszczyna .

.

.

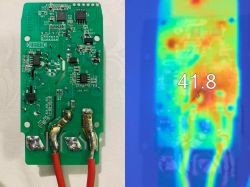

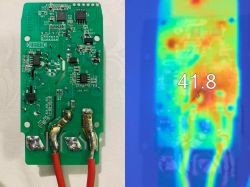

I came across an interesting photo on the internet taken with a thermal imaging camera.The photo shows a Sonoff POW R2 loaded with a 3kW receiver.

Is it possible to draw 3kW continuously from the module? As you can see, you can.

.

.

With the Shelly, be careful with the terminal strip too. You can easily twist the thread and big trouble ! It is worth taking the time to carefully arrange the wires, sometimes stiff ones, and tighten the screws with feeling. Forcing the module into the box with the handle of a hammer is a bad idea.

Shelly 1 is the 3rd version of this module. In previous versions, the modules burned out immediately after assembly. There are diagrams on the internet on how to connect the module correctly.

.

.

The Shelly 2.5 with power measurement is also a victim of the miniaturisation of this model and sloppy assembly.These, in turn, burst into live fire.

.

.

See for yourself there are videos on YT https://youtu.be/TTwb_0q8_Bk?list=RDCMUCRLJqSvuJHRySjdGRVH9Kmw .What I have shown and described are my comments. Those who did the firmware and software ...great. However, those who developed the hardware need to look at how the competition does it.

I have many different Shelly modules myself. I am reworking them a bit for my needs. I particularly like the Shelly RGBW2 and the Shelly Uni .

For Bulgarians I have a question .Is Shelly 1 safe ? Is it safe ? https://youtu.be/2xBJERznOgA?t=78

The red arrow shows how much insulation there is between the electronics(ESP8266) and the part of the PCB where the mains voltage is(230V AC).

By eye it is about 0.2mm.This is dangerous. Fear to install Shelly 1 in houses with wooden construction.

Shelly 1 version 3 has a voltage-free output, which means the relay contacts are isolated from the rest of the electronics. This isolation is 0.2mm from 230V circuits .Those who use the module e.g. to open the entrance gate and connect the relay contacts directly to the electronics of the drive can finish the expensive drive.It is better to use the power supply of the drive itself (mostly there is 12 or 24V) .People mostly power the module with 230V and so in the title .... the bomb is ticking and ticking.

.

.

It is also good to compare our Shelly 1 with similar designs e.g. the Sonoff we know.

I have been using SonOffs for many years and even when a lightning strike struck a pole near my house and several pieces of equipment gave up the ghost, all SonOffs survived. I have mixed feelings about Shelly. On the one hand, a great mobile app and on the other hand, the hardware part is dangerous.

.

.

Here the view from the elements. Well, and also uninteresting. The uninsulated leg of the resistor has been clipped onto the adjacent component so that the housing can be closed. The safety hangs on a layer of varnish. The consequence of such a squeeze can be seen here

.

.

Shelly 1 has a 16A relay and a load power of up to 3.5kW.Looking at the PCB we can see the thick tracks connecting the terminal block to the relay.

Here it is asking to whitewash these thick paths with a layer of tin (I crossed the soldering points with millimeter silver) .

.

.

At high currents the relay contacts get hot and heats up the solder leg in the PCB.Over time microcracks in the copper layer form around the solder point and arcing occurs. Solid thick tracks flooded with tin, electrical arc quenchers in the form of milled slots can be seen at Sonoff.

.

.

In the photo(from the net) is a Sonoff POW R2 PCB.This module controls two ski boot dryers, each with 1.5kW or a total of 3kW. I was worried whether this module would be able to withstand such power, but it has been in operation for 2 seasons and is OK.

Tin reinforced tracks can also be seen in the module from Pszczyna .

.

.

I came across an interesting photo on the internet taken with a thermal imaging camera.The photo shows a Sonoff POW R2 loaded with a 3kW receiver.

Is it possible to draw 3kW continuously from the module? As you can see, you can.

.

.

With the Shelly, be careful with the terminal strip too. You can easily twist the thread and big trouble ! It is worth taking the time to carefully arrange the wires, sometimes stiff ones, and tighten the screws with feeling. Forcing the module into the box with the handle of a hammer is a bad idea.

Shelly 1 is the 3rd version of this module. In previous versions, the modules burned out immediately after assembly. There are diagrams on the internet on how to connect the module correctly.

.

.

The Shelly 2.5 with power measurement is also a victim of the miniaturisation of this model and sloppy assembly.These, in turn, burst into live fire.

.

.

See for yourself there are videos on YT https://youtu.be/TTwb_0q8_Bk?list=RDCMUCRLJqSvuJHRySjdGRVH9Kmw .What I have shown and described are my comments. Those who did the firmware and software ...great. However, those who developed the hardware need to look at how the competition does it.

I have many different Shelly modules myself. I am reworking them a bit for my needs. I particularly like the Shelly RGBW2 and the Shelly Uni .

For Bulgarians I have a question .Is Shelly 1 safe ? Is it safe ? https://youtu.be/2xBJERznOgA?t=78