.

.

Welcome,

Today I will give a description of a simple repair of this multimeter. The equipment is popular enough that maybe someone less familiar with the subject will find this description useful and save his instrument

The meter on the ohmmeter range indicated all sorts of silly things, e.g. a 100 ohm resistor was identified as being up to several tens of kiloohms. Without the probes plugged in, it was also able to display some nonsense, and when the probes were short-circuited, instead of zero the display could show several hundred ohms or even more.

The first suspects were the batteries. I bought the meter in the first half of 2021 and it has been running on the same set of batteries ever since, and I use it the most out of all the meters I own. However, the cells turned out to be in pretty good shape, I even swapped them for new ones just to be sure, but it didn't do anything.

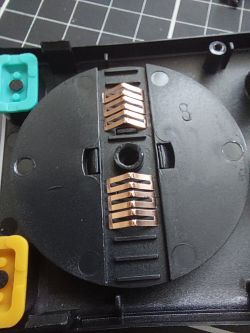

What I observed later, normal readings could be restored (but not always) by switching between ranges a few times. So the main suspect became the switch. To get to it the meter has to be disassembled, after dismantling the casing and removing the board we have this view:

.

.

You can see the switch tracks, they appear to be gold plated.

If you look closely you can see the oily ooze on the board:

.

.

This is probably grease that leaked from the switch and got on the PCB.

The part with the knob on the underside:

.

.

Here the contacts look OK, however I also washed them just in case.

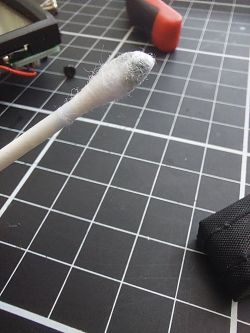

The switch tracks after cleaning:

.

.

You can see a huge difference, clean was not there:

.

.

Taking advantage of the fact that I had the meter open I also replaced the original 100uF electrolyte on the meter supply with a 1000uF:

.

.

This is one of the recommended modifications for this meter, you can read more here: https://www.elektroda.pl/rtvforum/topic3713925.html#18825243

Well, and now the most important thing: Was the repair successful, does the meter indicate as it should? Time to check!

.

.

It worked and the readings returned to correct

The whole repair took me ~ half an hour, cost 0zł

The switch, by the way, is a common problem with many meters, mainly because the power switch is usually placed there as well, so the switch wears out faster because of this.

Thank you for your attention.

Regards,

A.

Cool? Ranking DIY