Hello, I have dealt and still deal with detectorists, I have even written a little about it, even writing my master's thesis. I have even written a little about it, even writing my master's thesis. I have also dabbled in it as an amateur when I had the time.

First of all, I have to constructively deny the thing, which for a skilled electronics technician bites in the eye

.

Don't listen to YT-salesmen, just specific technical channels, gaining knowledge.

No metal detector measures and graphically indicates the conductivity of metals [S/m] - because some on the internets tell you such things.

It is impossible due to the fact that we do not directly know >> the shape, dimension, cross-sectional area, and resistance of the detected object.

Who will assess this underground and how ? ;]

Plus a theoretical and practical simple comparative example,

A simple example - silver is a very good conductor.

Check the reaction of the detector to a large 925 sterling silver ring,

check the reaction to a very thin chain of the same sample or a very thin small coin. In theory, apart from the size of the object, the metal alloy is identical, so the result should be similar (because a very good guide), and it won't be.

And compare it (relative to the chain) with some copper object, which should have a lower result no because it is a worse conductor, and it will turn out to be, for example, higher.

The detector indicates a certain value averaged and calculated according to the adopted algorithm - in short, some ratio of maximum values of vectors resulting from a certain signal received from the detection probe (generally this signal is generated into two components X and Y)

X In-phase (in-phase) Mainly resistivity, conductivity How much current it can let through - e.g. copper, silver give a strong signal in X

Y Quadrature (quadrature, 90° offset) Mainly reactivity, i.e. inductance and capacitance Whether the metal is ferromagnetic or not - e.g. iron reacts strongly in Y

Conductive metals (e.g. copper, silver)

- They give a strong signal in X (in phase) because they conduct well - large eddy current → strong response.

- The Y signal is low because they have no magnetic properties.

Magnetic metals (e.g. iron)

- They give a large signal in Y (quadrature) - the detector "sees" strong inductance (the material delays the signal response).

- The X signal is weak because the conductivity is lower.

And now yes: the calculated value (actually the phase shift of the base signal) will be characterised to some extent (what I have already described above) by the fact that we are able to distinguish between metal alloys because their el, physical properties will affect the phase shift - higher for paramagnetics, lower for ferromagnetics.

This happens through the induced electromagnetic field in the conductor (eddy currents), which are created by the transmitter's excitation of the detection probe.

This field generates a secondary electromagnetic field generated in the receiving section of the detection probe.

The probe is aligned, it has some sort of minimum balance signal (system balance).

The signal generated will have an amplitude that depends on the size of the object and its depth in the ground, and the phase shift will depend on the electrical properties of the object, its shape, size, angle of inclination, depth, thickness, soil, moisture content and more.

This shifted, induced signal is compared to the transmitter's reference signal - it is relative to this signal that it will be shifted in phase.

Generally, the signal is then demodulated in the electronics into two components corresponding to resistive, conductive and reactive values.

There is also the land component (but that is a separate topic).

These signals pass through bandpass filters and are then analysed (analogue or digital) - a ratio calculated, for example, or according to some other algorithm.

fi = arc.tan(y/x)

This will ultimately be the determinant of the angle of deflection of the resultant vector, which can then be calibrated and described graphically, audibly, numerically - e.g. -95 to +95.

The resulting analogue signal is also verified at the end of the detection system, e.g. by a pair of comparators which, against a separate discrimination module (analogue detectors), check whether to generate sound or to reject the signal from the detected object - discriminate.

Digitally, it's similar, but it tends to process the entire spectrum on the fly and simply responds to specific parameters set in some kind of pattern table.

So yes - better materials (conductors) will cause the signal to tend towards maximum vector bias, worse ones in the opposite direction.

But still, as I mentioned, many other factors will influence the definitive identification.

Because the fact that something beats e.g. at VDI = 90 (e.g. a silver ring , a large copper coin) does not classify that we are always dealing in the ground only with material of the "better conductor" classification.

This is because two materials, silver and copper, with obviously physically different conductivity, fall into the same number, but the VDI is definitely influenced by other factors, so that in theory a material with inferior physical electrical properties is on a par with one with better

it does not make the slightest sense if we would go back to the fact that the detector calculates, measures, indicates the conductivity of metals and on this basis classifies into better worse, it is not so simple

.

X - answers

- Conductivity σ (S/m) → the higher, the stronger the X signal

- Low resistivity ρ (Ω-m) → i.e. copper, silver, gold

- Slightly dependent on shape and depth

Y - corresponds to

- Magnetic permeability μ → ability to conduct a magnetic field (ferromagnetism)

- High reactance → e.g. with iron (strong delayed response)

- Predominantly non-conductive or weakly conductive metals

This is why the detector is said to present VDI numbers - Visual Discrimination Identification, i.e. the identification of the type of metal object likely to lie in the soil beneath the probe.

And some sort of scale is adopted, e.g. from -90 to +90.

Some range is calibrated for copper, lead, aluminium, silver, foil, iron, objects - caps, nails, specific coins, rings and conventionally assigned to the adopted scale.

Then you can comparatively infer what might be under the probe.

But further it is not measuring the conductivity of a specific object.

An ideal paramagnetic will swing the receiving signal in the +90 direction,

An ideal ferromagnetic will tend to swing in the opposite direction of the -90 scale

VDI is only a guide, it does not give 100%, because there are too many factors influencing the measurement result, and it also depends on the depth of the object.

There are also interesting issues of discrimination, i.e. deliberate omission or exclusion of some objects, and ground, which introduces an "interfering" signal for the electronic detection system and should be compensated so that the resultant signal vector "0" of the unawakened detector does not "escape" on the scale (possible false signals, incorrect indications, excitation), but set at the neutral point - the beginning of the scale..

Because the ground itself can also have conductive , magnetic and other properties, so it physically induces a signal in the receiver coil of the detector and this should be nullified at the outset.

I encourage you to read the articles of the monthly magazine Discoverer on the construction of detector >>> series by Mr Proscan from Gliwice, who is one of the "gurus" when it comes to knowledge of principles and assemblies. He has his own proprietary solutions, but mainly deals with service.

For the more inquisitive, there are several English-language items on detector construction and even home experiments step by step designing simpler circuits for the final device.

(Inside the metal detectors)

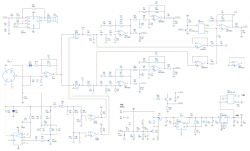

A properly repaired detector (above) should additionally be connected and tested complete with a detection probe, which forces the whole transmitter/receiver system. The whole thing should of course preferably be connected to an oscilloscope at the appropriate measuring points and then checked for correct probe compensation, signal generation from the detected object, X/Y channels, ground response, ground imitation and response to various objects etc

.

Detectors in general are a very cool and interesting topic.

Greetings!

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

<br/span> <br/span>

<br/span> <br/span> .

.