Hi,

i am creating a thermometer for the smokehouse ... .

.

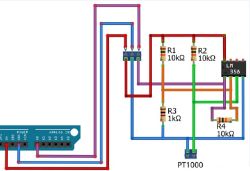

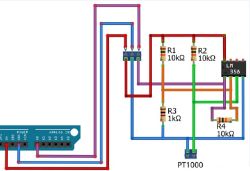

I have managed to make an analogue temperature sensor based on a PT1000 sensor at this point. It comes in a gel cable. According to the manufacturer the range can be -50*C-200*C. I managed to get max. 144*C. I don't know if the LM358 limits this ?

The PT1000 sensor is supposed to measure the smoke temperature.

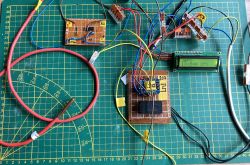

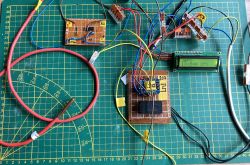

The circuit is based on an ESP8266 Wemos. It is accompanied by an LCD1602 display. I'm running on ESP Easy and I'm fine with it.

I may do a second option with zaSUPLOwing - Supla has a good readable app on the tel.

I calibrated the sensor at two points : at 100*C and 0*C. I also fitted a second sensor : DS18B20, but this one will be as an outdoor temp, or a sensor to stick in the meat.

I would still like to do e.g. a fiddly thing like some sort of buzzer when the temperature rises, or falls below the range, to either boost or dim.

i am creating a thermometer for the smokehouse ...

I have managed to make an analogue temperature sensor based on a PT1000 sensor at this point. It comes in a gel cable. According to the manufacturer the range can be -50*C-200*C. I managed to get max. 144*C. I don't know if the LM358 limits this ?

The PT1000 sensor is supposed to measure the smoke temperature.

The circuit is based on an ESP8266 Wemos. It is accompanied by an LCD1602 display. I'm running on ESP Easy and I'm fine with it.

I may do a second option with zaSUPLOwing - Supla has a good readable app on the tel.

I calibrated the sensor at two points : at 100*C and 0*C. I also fitted a second sensor : DS18B20, but this one will be as an outdoor temp, or a sensor to stick in the meat.

I would still like to do e.g. a fiddly thing like some sort of buzzer when the temperature rises, or falls below the range, to either boost or dim.