>>21753023 ;D Much health wishes

acctr wrote: Such is the characteristic of 3D printing that objects have a texture of poor quality. And this does not only affect the aesthetics but also the usability side because the surface easily collects dirt and dust, which is hard to remove.

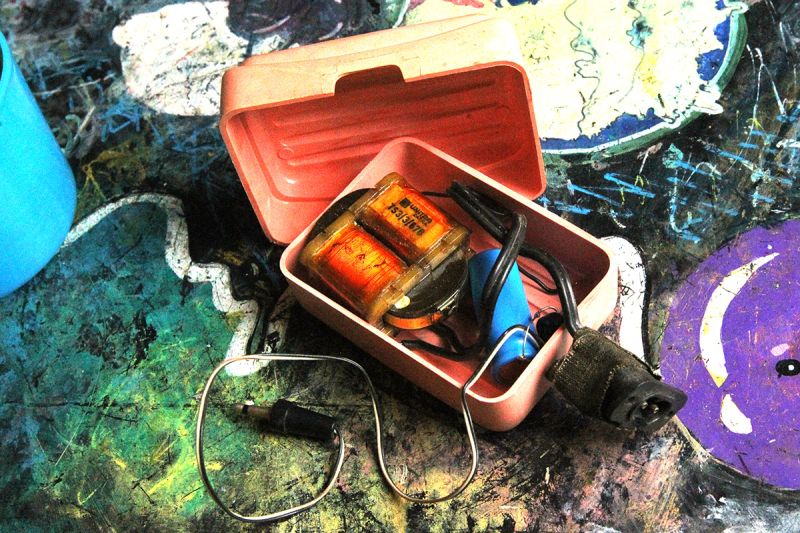

Mobali wrote:

that is to say, if someone thinks the 3d printing texture is nice and even likes it, that means they have to be sent to Kobierzyn? ;d

acctr wrote: Explain where you see this functionality apart from the sizable volume that a box of similar size fulfils.

Well yes, why buy a lawn mower when you can mow with scissors, after all it fulfils the same function

oshii wrote: If you do something exclusively for yourself - full agreement. If you (for a fee) make it available to others, who I assume trust that the project has passed the prototype stage, and yet afterwards the top cover warps into a slight banana, then imho it is worth digging deeper into the subject.

with me this problem has been solved, all I had to do was straighten the print slightly and it is straight. The photo I posted in the head post was taken a long time ago, when the top was still PLA (a material with low thermal resistance), which ended up "melting", which is why the instructions say that PETG is a better choice

oshii wrote: I assume that you redesigned the rear panel in the final version, because so strice from the aesthetic point of view the mutual arrangement of inputs/outputs/switches leaves a little to be desired.

remains as it is

oshii wrote: 1. Connecting the power supply directly to the GPIO pins is not a recommended practice; you bypass the whole power input circuitry and voltage/power negotiation.

What power supply are you using? As far as I can see 5V and GND goes directly from the socket. Since you are bypassing the usb-c of the raspberry itself, most power supplies, except maybe the official one won't allow enough current to flow to power the raspberry itself, let alone the expansion card and screen.

ok thanks for the insight! i had no idea about that. 5V/2A power supply from botland. In your opinion how else to connect the power supply?

oshii wrote: 2. Are you satisfied with the screen used? From experience, such screens have b.poor blacks and b.poor viewing angles, among other things, which is why I personally would rule them out at the start, because with intimate lighting, looking from the side they simply look bad.

Yes I am! I'm usually looking at it straight on, so I don't mind poor angles (if there are any)

oshii wrote: 3. Have you made sure the RJ-45 terminals go in well, even if the cable has extra covers? Because it seems to me that a more heavily shrouded plug might not want to plug in, so either there would have to be a recess on the outside, or a dressed material on the inside and a shallower socket because of that.

2

Yes, everything goes in as it should

bsw wrote: The author clipped together some ready-made modules, installed a ready-made distro, put it in a case that printed itself and voile - it's diy. And you can still make money from it - but absolutely no criticism is allowed because it is hate speech...

At what point did anyone mention hate speech?

fabulism and over-interpretation I see is a common trait, of people who miss the "good" old electrode

tytka wrote: It's a pity you didn't try to enrich the project with your own invention (apart from the enclosure).

yes that's right, it was a project that was going to be replaced by something "richer", but unexpectedly it got so much positive feedback that I shied away from doing something "more expensive". This is a cheap enclosure that you can print yourself, assemble yourself and be happy that something you assembled yourself performs a certain function

tytka wrote: And somehow I still don't have the courage to put my "products" on sale

i was also afraid, but I persevered, and I got profits out of it. but no wonder, when you read the "truest and most important" opinions of old-electro-designers, you get discouraged ;D

efi222 wrote: The print straight from the printer's table is simply ugly.

in your opinion, I personally like it. but everyone has their own style and their own taste

cinepi wrote: All in all, I think it's only the aesthetics of the screws that could be complained about - the front ones are still ok, although they could have a lens head or be blackened. The rear ones - preferably in the same style as the front ones, or at least with chamfered holes to hide the 4 screws securing the rear panel. The rest as OK as possible.

Thanks very much, I specifically gave the allen screws protruding because I just like them. There will be some on the back as well, but they are not "in stock" at the moment

khoam wrote: I suggest that for DIY publications only AI can ask questions. In "Friendly" mode. This will keep the DIY author's comfort zone intact.

As you are already suggesting so much here and sprinkling good advice, I also have a suggestion for you: Set up a forum/group on facebook (whatsapp) or a group chat on messenger called "electrode turnbuckles" (kmwtw ;D) where one activity will be to whine about how everything is now and that it used to be better and now it's worse, and the other - the last activity - will be to set new rules and definitions for words and phrases that only suit you :S