Printing with a laser printer on a PCB laminate

Some time ago I successfully converted EPSON P50 into a printer that directly prints on the laminate. The effects were very satisfying for me, but the whole difficulty is to find an appropriate waterproof ink. I personally did not succeed in this, which is why I used the hybrid method (printing on an inkjet printer with "waterproof"inks, then sprinkling the toner and then heating the disc), but this method, although cool (it is possible to describe the plate) and quick has a disadvantage, which is the constant memory of cleaning and maintaining the head/carcass in proper order (although by switching on once a week).

A few years ago, I was wondering whether it was possible to print on pcb with a laser printer and everybody said they were not. There are currently several pages showing printer upgrades so that you can print directly onto pcb. I decided to try it out using the description of the factory modification of a new and cheap printer (unfortunately expensive toner) from this website: https://www.instructables.com/id/Modification-of-the-Pantum-2502W-for-Direct-Laser-/ but using cheaper versions without wi-fi (Pantum 2502 without "W" all parts are identical.

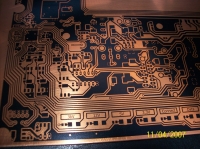

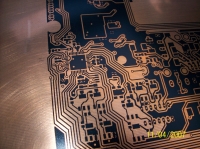

I would like to show you the result in the form of several photographs and a movie, here:

Seeing as well as practicing "iron methods" they are personally for me a "murder". In this method (although more expensive) as well as printing on an inkjet printer, in fact, after designing the plates on a computer for etching they divide a second/minute and as well as how I "worked out" you do not even need great rigours with regard to degreasing.

This fast I dedicate mainly to people who hesitated (I myself had a fear) to try this method.

A few years ago, I was wondering whether it was possible to print on pcb with a laser printer and everybody said they were not. There are currently several pages showing printer upgrades so that you can print directly onto pcb. I decided to try it out using the description of the factory modification of a new and cheap printer (unfortunately expensive toner) from this website: https://www.instructables.com/id/Modification-of-the-Pantum-2502W-for-Direct-Laser-/ but using cheaper versions without wi-fi (Pantum 2502 without "W" all parts are identical.

I would like to show you the result in the form of several photographs and a movie, here:

Seeing as well as practicing "iron methods" they are personally for me a "murder". In this method (although more expensive) as well as printing on an inkjet printer, in fact, after designing the plates on a computer for etching they divide a second/minute and as well as how I "worked out" you do not even need great rigours with regard to degreasing.

This fast I dedicate mainly to people who hesitated (I myself had a fear) to try this method.

Comments

This method has one major disadvantage. The laminate must be perfectly straight, of appropriate thickness and perfectly polished. :) [Read more]

Let me disagree :) Well, if you look good, it's not a simple laminate at all. In addition, it has a tape (from the front of the tile) protecting against scratches of the photosensitive drum. Testing... [Read more]

and the name of this agent you do not give in both the first and the second post because, because ...? [Read more]

silicon w spreyu ;) [Read more]

What? And how is copper consumed by silicone ?? [Read more]

It is a silicon spray, which is used to prevent the seals from freezing in the car. Can I digest this silicon? The answer is, I have no idea :) Well, you just need water with washing powder or the... [Read more]

You can make 2 1-sided prints by your way and connect them with pins with empty pages but you probably know. I have such an idea to use the 3D printer reprap for this operation, instead of, or by coupling... [Read more]

Well, you're right. By editing the printer from the description given at the very top, through the rush the only thing that I managed to spoil is a photoconductor. Unfortunately, the toner with it is expensive,... [Read more]

All the time I go to my head to cover the laminate with a thin layer of black paint and burn the paths with a CNC laser. And then in the etchant. [Read more]

For what reason, if 99% of the programs have the option of exporting to HPGL, hence the banal to g-code :) . @lukasku How is it that photos you have from 2007, how the Pantum company was... [Read more]

He did not want to set the date on the camera :D What is this copper so discolored? [Read more]

Probably so. ;) This discoloration of Piotr, probably after the iron - too high temperature and poor laminate. [Read more]

Exactly :) Not after the iron. Well, one of the few things when modifying the printer is the disassembly of the heater / heater. "Print" is a bit "dry" (even without the use of silicon, the... [Read more]

Is something else important yet the blocking mechanism must be removed and the laminate heated before passing through the printer? [Read more]

In this link, http://www.instructables.com/id/Modification-of-the-Pantum-2502W-for-Direct-Laser-/ is nicely described with pictures. If I remember correctly, one roll, heaters, make a plate guide and place... [Read more]

I understand that the plate goes to the oven for fixation, and what about the acetone trick shown here: https://www.youtube.com/watch?v=VY-7hQ6ocx8 [Read more]

This is a slotted optocoupler, no reed switch. [Read more]

I have not tried (my plate is 190x190), but it probably works. As soon as I'm doing a new (smaller) plate, I'll try and check it out. Thanks for the correction. My bad. [Read more]

I've just tested a 405nm laser diode (about, it's blue for violet) and a photosensitive resin (I plan to make a 3D printer but it's cool) and practically harden the 0.1mm layer immediately. As if instead... [Read more]