Why film capacitors lose their capacity - MKP X2 capacitor section

Recently, a remote-controlled 230V socket stopped working for me. The relay did not respond to commands sent from the 433MHz radio remote control. Such simple devices use a transformerless power supply, I suspected a short circuit on the zener diode, the reason was damage to the foil capacitor MKP X2 330nF. The capacitor lost its original capacity and at 160nF the power supply to the system was not correct. In newer devices (eg Sonoff) we can find impulse power supplies, in which electrolytic capacitors or SMPS control keys / circuits are damaged. In the case of foil capacitors, probably most of us have heard about their ability to do self-regeneration (depending on the type of capacitor). The breakdown of the dielectric leads to a short circuit and local evaporation of the conductive layer sprayed on the foil, when the layer evaporates, the short circuit is resolved simultaneously. The design of the foil capacitor was visible in old foil capacitors, where there was no casing around the rolled foil constituting a dielectric surrounded by conductive covers on both sides.

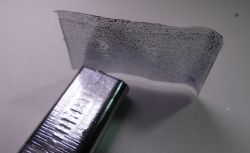

However, can such phenomena reduce capacity by nearly 50%? Looking for information about the reasons for the loss of capacity by the MKT and MKP film capacitors, I found the page link where can you find out that foil capacitors are getting damaged by corona discharges . Corona discharge occurs due to air getting between the foil and the sputtering aluminum covers of the capacitor. The loss of the capacitance of the capacitor reduces the current efficiency of the transformerless power supply, the output voltage is reduced and, for example, the device resets or the relay that requires more power to operate cannot be switched on. The yellow capacitor casings of the timer and power meter are visible below:

Film capacitors can also be found in anti-interference filters. The capacitors connected between the phase (L) and neutral (N) conductors will be marked with X (in the example X2 - the number indicates the voltage withstand). In anti-interference filters, you will also find capacitors marked as Y, they are connected between the work conductor and the protective conductor.

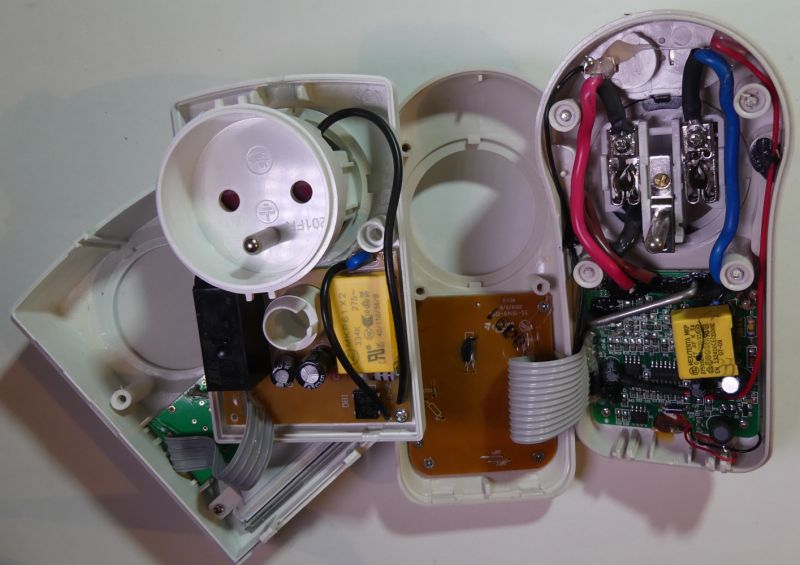

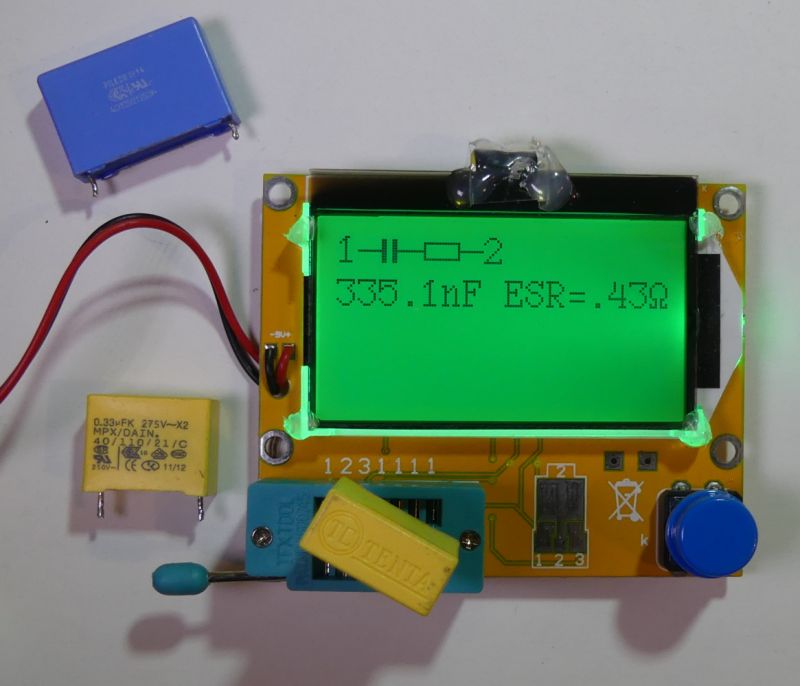

Measuring the capacity of a damaged and new capacitor that will be installed to repair a wireless outlet:

Let's see what the damage inside the capacitor looks like,

first the fight with the housing:

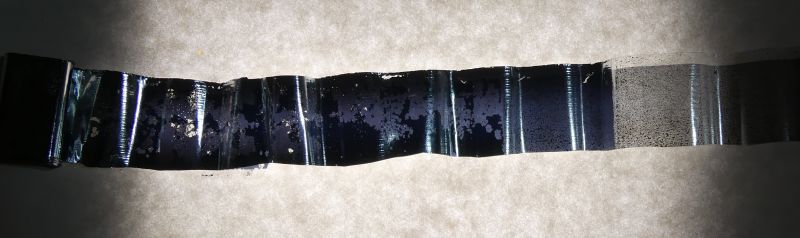

We unfold the capacitor and you can see the remains of the sputtered conductive layer:

It turns out, however, that this is the beginning of the capacitor and this "launch tube" constitutes some kind of protective / insulating layer, the last turns of the capacitor look the same. As we expand more, the layer becomes darker.

When we highlight the foil, it turns out that there are visible damages similar to those found in the article. Damage occurs practically along the entire length of the foil.

I started to wonder if this is really damage, or maybe an imperfect sputtering process, or maybe it is me who cyclically damage the metallization by unwinding the capacitor?

I decided to develop a functional capacitor desoldered from another device.

Initially, we have a "starter" foil:

Then uniform metallization appears:

This confirms that the found article rightly identified the cause of damage to the foil capacitors, the progressive degradation of the sputtered conductive layer lowers the capacitance of the capacitor.

Have you come across damage to the MKT / MKP foil capacitors, in what devices?

Source:

https://gideonlabs.com/posts/ic-emi-mkp-33uf-film-capacitors-failures/

https://www.ecicaps.com/tech-tools/technical-...failures-metallized-polypropylene-capacitors/

However, can such phenomena reduce capacity by nearly 50%? Looking for information about the reasons for the loss of capacity by the MKT and MKP film capacitors, I found the page link where can you find out that foil capacitors are getting damaged by corona discharges . Corona discharge occurs due to air getting between the foil and the sputtering aluminum covers of the capacitor. The loss of the capacitance of the capacitor reduces the current efficiency of the transformerless power supply, the output voltage is reduced and, for example, the device resets or the relay that requires more power to operate cannot be switched on. The yellow capacitor casings of the timer and power meter are visible below:

Film capacitors can also be found in anti-interference filters. The capacitors connected between the phase (L) and neutral (N) conductors will be marked with X (in the example X2 - the number indicates the voltage withstand). In anti-interference filters, you will also find capacitors marked as Y, they are connected between the work conductor and the protective conductor.

Measuring the capacity of a damaged and new capacitor that will be installed to repair a wireless outlet:

Let's see what the damage inside the capacitor looks like,

first the fight with the housing:

We unfold the capacitor and you can see the remains of the sputtered conductive layer:

It turns out, however, that this is the beginning of the capacitor and this "launch tube" constitutes some kind of protective / insulating layer, the last turns of the capacitor look the same. As we expand more, the layer becomes darker.

When we highlight the foil, it turns out that there are visible damages similar to those found in the article. Damage occurs practically along the entire length of the foil.

I started to wonder if this is really damage, or maybe an imperfect sputtering process, or maybe it is me who cyclically damage the metallization by unwinding the capacitor?

I decided to develop a functional capacitor desoldered from another device.

Initially, we have a "starter" foil:

Then uniform metallization appears:

This confirms that the found article rightly identified the cause of damage to the foil capacitors, the progressive degradation of the sputtered conductive layer lowers the capacitance of the capacitor.

Have you come across damage to the MKT / MKP foil capacitors, in what devices?

Source:

https://gideonlabs.com/posts/ic-emi-mkp-33uf-film-capacitors-failures/

https://www.ecicaps.com/tech-tools/technical-...failures-metallized-polypropylene-capacitors/

Comments

I think an identical one, also yellow, fell in the coffee grinder. Connected in series in a transformerless power supply. I put an old Russian capacitor from the TV board on 400V and the grinder has been... [Read more]

Transformerless power supplies were also used in Soviet flashlights The capacitors used there were also indestructible, while the batteries were quite hopeless. [Read more]

At work, we had a similar problem with the capacitors in the flap actuators in the process. These capacitors were connected to the 2-winding motor and when the capacitance decreased, the motors rotated... [Read more]

I have the most trouble with the so-called "potatoes", foil capacitors flooded with some starch filling. They were used in TV and radio tube receivers from the beginning of the 70s and older. TIMES more... [Read more]

@TyratrooN I know the ones flooded with resin, they were pretty good, I also remember foil capacitors that look like "potatoes" but are inserted into a glass tube covered with tar on both sides. Tar... [Read more]

For more than a dozen years, I have known this phenomenon from practice. It used to be motor capacitors. Today, series capacitors in transformerless power supplies are the first and usually only suspect. I... [Read more]

Why are you surprised? Once, long ago (20-30 years), the drying of electrolytes was incidental. I know RTV products (from those years) which, if used today, work without replacement, even the small, most... [Read more]

@TechEkspert It was in such devices, where the controller provided 230V AC to the motor via relays. https://obrazki.elektroda.pl/8218348700_1601485482.png [Read more]

Here is a similar topic https://www.elektroda.pl/rtvforum/viewtopic.php?t=3671173&highlight= [Read more]

I have encountered this problem in most modern devices in which the power supply is transformerless and the device has a relay inside, the coil of which is powered from this type of power supply. I replace... [Read more]

Hi - and isn't the result of the above-mentioned defects sometimes incorrect thickness of the foil used, ecology in the production of plastic (foil) + better sealing of the capacitor? Film sputtered... [Read more]

Hello I had the same situation, the CO furnace controller [from a well-known company] was turning off the message high mosfet temperature in the power supply the capacitor had less than 300nF of capacity... [Read more]

Strictly speaking, we have an in-depth description of the damage mechanism here, and not the real reason and how to prevent it. I just started replacing the capacitors in a series of identical motion... [Read more]

It seems to me that the power is "pumped" through the capacitor and this is the reason for the degradation of the coated linings (I do not know the technology of producing these capacitors). Probably the... [Read more]

In my opinion, the main reason is too high impulse currents flowing through the capacitor, each inclusion generates such inclusion, it is limited by the 100om resistor visible in the picture, but it is... [Read more]

Hello Currently, transformerless power supplies based on a series capacitor are replaced by miniature switching power supplies on an integrated circuit of the LNK304 type or similar. They are mainly... [Read more]

Not so much power, but quite a lot of current flows, from a few to a dozen or so mA, which is a considerable value for a very thin, sputtered layer of capacitor linings and causes their degradation. ... [Read more]

I repaired a few with this power supply (problems other than the power supply) and they have been working for about 15 years. A week ago I was repairing my Polar PTL819 sister washing machine (Whirlpool... [Read more]

When I post material on elektroda.pl, it usually happens that either I learn something very interesting from the comments, or later the information from the material comes back to my mind when I solve... [Read more]