Cell welding machine on Chinese DIY driver

Hello

I would like to present for evaluation, possibly to indicate errors and defects of my cell welding machine.

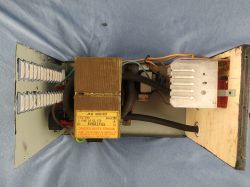

I do not have access to professional tools, so the housing looks like it looks. It is made of metal sheets left over from a microwave oven, the front part is made of plywood because of easier processing.

What should be changed in it:

- convert the cable from 25 mm2 to 35 mm2

- press the ring terminals with a hydraulic press

- replace aluminum elements with copper ones in the handle with electrodes

Initial parameters:

1300 W transformer

Secondary winding cross-section 25 mm2

The voltage of the secondary winding is 3.3 V

Short-circuit current on the secondary winding 750 A (the meter has a scale of up to 600 A)

The 40 A driver and electrodes were purchased on aliexpress.

Current parameters:

Secondary winding voltage 5V

Short circuit current on the secondary 910 A

A video showing the production of the welding machine:

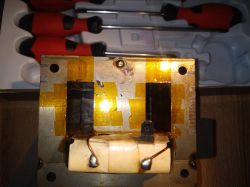

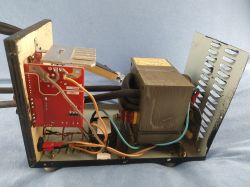

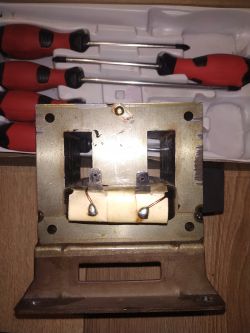

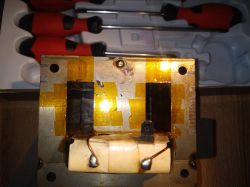

Photos of the welding machine:

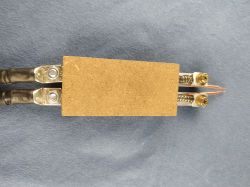

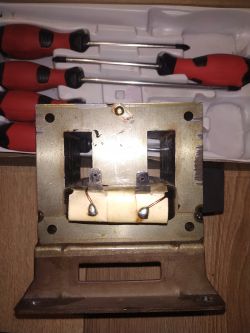

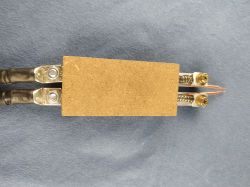

To make the handle of the welding machine, I used aluminum flat bars, dedicated welding electrodes, springs, screws, OSB and plastic.

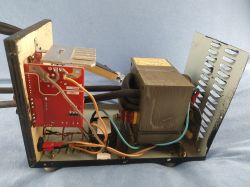

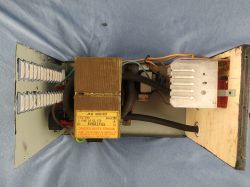

The inside of the welding machine

I temporarily insulated the side wall of the welding machine with paper (probably barley) before any contact with the controller.

Update 9/11/2020.

Today I made modifications to the welding machine. The insulation was stripped from the 25 mm2 wire, instead I used two layers of Kapton tape and paper insulation (probably barley). Thanks to this, a few more turns came in and the voltage increased to 5 V.

Update 10/11/2020.

I have assembled everything, the result is 910 A. All that is left to do is to make electrode handles and the project is completed.

I would like to present for evaluation, possibly to indicate errors and defects of my cell welding machine.

I do not have access to professional tools, so the housing looks like it looks. It is made of metal sheets left over from a microwave oven, the front part is made of plywood because of easier processing.

What should be changed in it:

- convert the cable from 25 mm2 to 35 mm2

- press the ring terminals with a hydraulic press

- replace aluminum elements with copper ones in the handle with electrodes

Initial parameters:

1300 W transformer

Secondary winding cross-section 25 mm2

The voltage of the secondary winding is 3.3 V

Short-circuit current on the secondary winding 750 A (the meter has a scale of up to 600 A)

The 40 A driver and electrodes were purchased on aliexpress.

Current parameters:

Secondary winding voltage 5V

Short circuit current on the secondary 910 A

A video showing the production of the welding machine:

Photos of the welding machine:

To make the handle of the welding machine, I used aluminum flat bars, dedicated welding electrodes, springs, screws, OSB and plastic.

The inside of the welding machine

I temporarily insulated the side wall of the welding machine with paper (probably barley) before any contact with the controller.

Update 9/11/2020.

Today I made modifications to the welding machine. The insulation was stripped from the 25 mm2 wire, instead I used two layers of Kapton tape and paper insulation (probably barley). Thanks to this, a few more turns came in and the voltage increased to 5 V.

Update 10/11/2020.

I have assembled everything, the result is 910 A. All that is left to do is to make electrode handles and the project is completed.

Comments

Hi Pretty decent execution, - how do the seals come out? - what are your welding times, number of pulses? I will add right away that your output voltage is too low, I recently finished my welding... [Read more]

From this you should get at least 900-1100 A. There are many mistakes here, but the best way is to look for yourself rather than ask for advice. I have been building my welder for over 1.5 years, perfecting... [Read more]

The welds at 0.15 mm nickel plate come out nice for me, that's what I use. 1 pulse, time 0.2, I set the welding power to the maximum value. Yes, realizes that the voltage is low. When I need more... [Read more]

Nice layout, nicely made, I made a welding machine myself, but I went the simpler way, my control system consists of exactly 10 electronic components, smooth pulse time adjustment using a sliding resistor,... [Read more]

If it works and it works without failures, that's fine. Thanks for the opinion. So I quickly checked the new electrodes: https://obrazki.elektroda.pl/6749135000_1604933420_thumb.jpg htt... [Read more]

I have a question: how did you record a video on YouTube that you can see everything how you work? A webcam on the head or what? Best regards and congratulations on a successful project. [Read more]

Thanks. The key here are two photo bulbs placed on tripods. Sometimes I put on softboxes, they give a better effect. I shot the film with the Redmi 6 phone placed on a photo tripod. Regards too. [Read more]

Well, this video came out very well and professionally, it's nice to watch. I asked because I would like to start having fun with filming my work and uploading it to my website (or YouTube, in fact).... [Read more]

I used the Triopo GX-1127 Carbon with the Triopo B2 head and a phone mount for a few zlotys. You can safely use a cheap tripod - it does not matter when you are on the phone. I have the following lighting... [Read more]

See here the same driver with pure nickel 0.2 mm thick, the welding machine is able to weld any number of plates. Now I'm waiting for copper. I want to weld copper plates 0.2 mm. https://youtu.be... [Read more]

I will add that you are not truthful ;-) If you don't believe me, I invite you to see my design. Link at the bottom in featured. [Read more]

SylwekK, do you weld anything other than a nickel-plated plate? With pure nickel, the higher the tension, the better the welding. [Read more]

I weld, e.g. stainless steel. [Read more]

I meant welding to cells. There, either nickel-plated steel or almost pure nickel is used (almost, because the nickel content is 99.6%), it is about the shortest possible welding time. I am welding nickel... [Read more]

Maybe so, but in your construction the length of the cables leading to the electrodes has been reduced to the necessary minimum and the 2.9 V looks that it is enough. In my welding machine it did not work,... [Read more]

@ radomski99a, see the bottom of the post. Nickel-plated sheet (i.e. the most popular). The lowest parameters that I can set, i.e. 10ms / 10ms, create a durable and nice weld. https://www.elektroda.pl/rtvforum/viewtopic.php?p=17903368#17903368 ... [Read more]

Yes, I blew inductive bridges. It is possible that the welding sockets used are an effect of this. [Read more]

I was interested in this driver from Aliexpress. Is there a fundamental difference between the 40A and 100A versions? [Read more]

In a single-phase network, 40 A is more than enough. [Read more]