Hello

I would like to present for evaluation, possibly to indicate errors and defects of my cell welding machine.

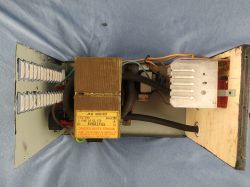

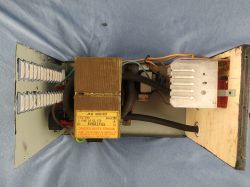

I do not have access to professional tools, so the housing looks like it looks. It is made of metal sheets left over from a microwave oven, the front part is made of plywood because of easier processing.

What should be changed in it:

- convert the cable from 25 mm2 to 35 mm2

- press the ring terminals with a hydraulic press

- replace aluminum elements with copper ones in the handle with electrodes

Initial parameters:

1300 W transformer

Secondary winding cross-section 25 mm2

The voltage of the secondary winding is 3.3 V

Short-circuit current on the secondary winding 750 A (the meter has a scale of up to 600 A)

The 40 A driver and electrodes were purchased on aliexpress.

Current parameters:

Secondary winding voltage 5V

Short circuit current on the secondary 910 A

A video showing the production of the welding machine:

Photos of the welding machine:

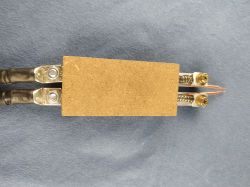

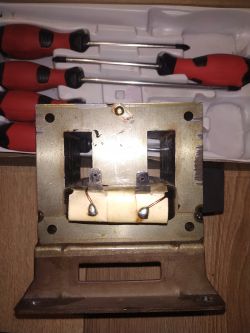

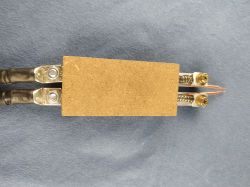

To make the handle of the welding machine, I used aluminum flat bars, dedicated welding electrodes, springs, screws, OSB and plastic.

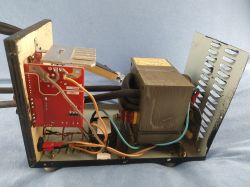

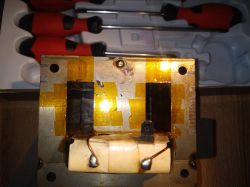

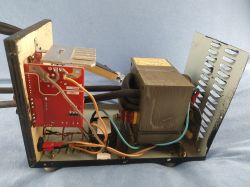

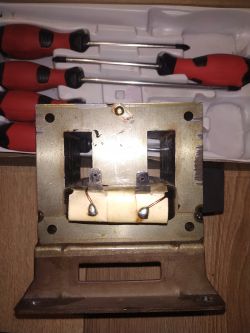

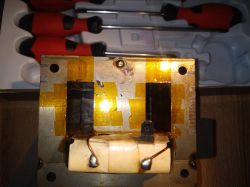

The inside of the welding machine

I temporarily insulated the side wall of the welding machine with paper (probably barley) before any contact with the controller.

Update 9/11/2020.

Today I made modifications to the welding machine. The insulation was stripped from the 25 mm2 wire, instead I used two layers of Kapton tape and paper insulation (probably barley). Thanks to this, a few more turns came in and the voltage increased to 5 V.

Update 10/11/2020.

I have assembled everything, the result is 910 A. All that is left to do is to make electrode handles and the project is completed.

I would like to present for evaluation, possibly to indicate errors and defects of my cell welding machine.

I do not have access to professional tools, so the housing looks like it looks. It is made of metal sheets left over from a microwave oven, the front part is made of plywood because of easier processing.

What should be changed in it:

- convert the cable from 25 mm2 to 35 mm2

- press the ring terminals with a hydraulic press

- replace aluminum elements with copper ones in the handle with electrodes

Initial parameters:

1300 W transformer

Secondary winding cross-section 25 mm2

The voltage of the secondary winding is 3.3 V

Short-circuit current on the secondary winding 750 A (the meter has a scale of up to 600 A)

The 40 A driver and electrodes were purchased on aliexpress.

Current parameters:

Secondary winding voltage 5V

Short circuit current on the secondary 910 A

A video showing the production of the welding machine:

Photos of the welding machine:

To make the handle of the welding machine, I used aluminum flat bars, dedicated welding electrodes, springs, screws, OSB and plastic.

The inside of the welding machine

I temporarily insulated the side wall of the welding machine with paper (probably barley) before any contact with the controller.

Update 9/11/2020.

Today I made modifications to the welding machine. The insulation was stripped from the 25 mm2 wire, instead I used two layers of Kapton tape and paper insulation (probably barley). Thanks to this, a few more turns came in and the voltage increased to 5 V.

Update 10/11/2020.

I have assembled everything, the result is 910 A. All that is left to do is to make electrode handles and the project is completed.

Cool? Ranking DIY