.

.

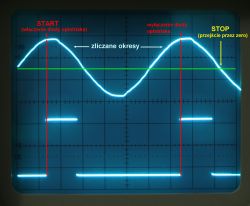

I built a welding machine a few years ago, it was mainly to be used to weld cells into packages. I have a lot of cast-off components, so I'm trying to put at least some of them to some use. Unfortunately this is going with increasing resistance, but that's another topic. So the result is a rather unusual, processorless circuit, altogether simple and cheap, but not lacking in important features. Many welding machine controllers have a disadvantage, despite a stable pulse time, there is no control of the moment when the transformer is connected to the mains, and in the mains, as it is in the mains, the voltage changes all the time. As a result, the portion of energy supplied to the welding spot varies, which can result in burning out the cell or in too weak a weld, as well as overloading the network and tripping the protections. With this in mind, this design was developed:

.

.

Unfortunately, as it turned out after commissioning, there was a welding time instability, burning out one in 20-30 cells. A ghastly occurrence, fortunately nothing exploded, but you had to pry this burnt cell out of the pack, so overall a big bummer. I tried to find the cause of this instability, modified something there, but it didn't get much better until I finally put the circuit away for lack of time. I occasionally used this welder, with small packets the job usually worked.

Quite recently the need arose to weld a larger packet, I decided to redo the whole controller at the same time.

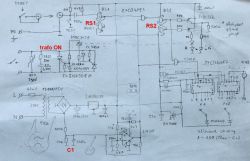

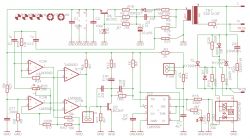

A schematic was created:

.

.

Maybe it will be useful for someone, also a simple chip without a processor, whether this is a disadvantage or an advantage I will leave to the readers to choose.

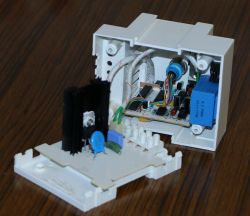

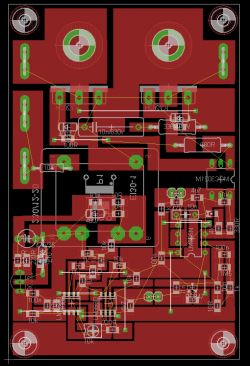

Untreated board, specially designed for my CNC woodworker. Simple copper layer cuts, significant milling inaccuracy allowed, easy post processing.

.

.

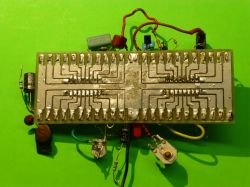

The new arrangement worked well, I welded the package, almost 300 good welds

in a row, except that... wanting to speed up the work, the driver was still in spider form, I made the board later. After fitting the new board, I did a few test welds, and it seems to work just as well, which is not at all obvious. Those who know know that spiders can work sensationally, and it is only the making of the plate that spoils the effect.

How it works.

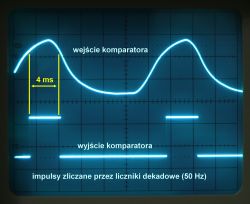

The power circuit consists of a 10-20V 2W transformer, a single-pole rectifier, a single-transistor voltage limiter-stabiliser feeding the circuit. The AC voltage from the transformer via the divider goes to the phase shifter IC3A and further to the comparators that detect the zero crossing, Zero in this circuit is half the supply voltage. The phase shifter is there to be able to hit the peak of the sine wave, which is when there is the least current surge when switching on the high-power tray. Is this successful? Experiments show that this surge can indeed be reduced by adjusting the phase with potentiometer R25. A shifted zero is detected which indicates the peak of the sine wave. A pulse at the peak of the mains voltage appears at the output of the comparators. This signal via the S microstep triggers the LM555 timing circuit. Then it is typical, the optotriac switches on the thyristors, I wanted to use what I have, so here sit the Russian KY202h, but if I burn them all, you can of course insert other newer ones, the board is quite universal.

Power trafo standard from microwave, 4 coils I think 16mm, long time ago I wound it I don't remember exactly.

.

.

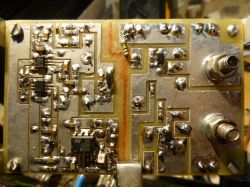

Spider testing platform.

.

.

Cool? Ranking DIY