From the electronics archive - selsyns

Some of the forum members probably remember circuits based on selsyns, nowadays selsyn links have been practically completely supplanted by modern solutions.

Imagine that you are given the task of designing a circuit that transmits information about the pivot of the axis of one of the machines to a distant control room.

This could be, for example, the position of the wind direction indicator, the rudder of a ship, or the angle of opening the door of a nuclear shelter.

Depending on the characteristics of the machine, an encoder (preferably absolute) or even a potentiometer can be used to determine the position of an element.

Information from the sensor can be transmitted by wire as an analog signal or as a digital signal via a copper, fiber-optic, perhaps radio link.

As an indicator, an LCD display or even an analog pointer can be used, generally anything that will clearly transmit the information to the operator.

You will probably give many more possible implementations of the system.

Let's assume that you have successfully completed the project, the appetite of the ordering party grows, and this time you are given the task of building a system that will allow you to move a part of the machine by a given angle depending on the settings on the control panel.

This time we control the throttle that allows you to dispense liquid to some machine.

The part that takes the data on the settings can be an encoder, a potentiometer, as well as a numerical panel. Transmission of any kind as long as it is reliable. On the other side of the transmission channel, you can use a servo motor, which will set the axis in the desired position depending on the received signal. In some cases, you may decide to use a controller and a stepper or DC motor with a gearbox and a system that tracks the position of the axis. In less demanding applications, you'll probably be tempted by a modeling servo.

Solutions again can be multiplied for quite a long time.

Now let's assume that under strange circumstances you go back in time 50 years and are given the task of making the above two circuits.

It turns out that there is a problem with buying systems of modern automation

After describing the problem, it turns out that the solution to both the task of transferring information about the angular position of the shaft, as well as remotely rotating the shaft (doing the work) by a given angle is selsyn.

What are selsyns?

After reading the text so far, you know exactly what tasks selsyns can perform, but how are they built?

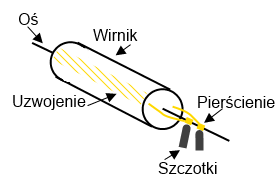

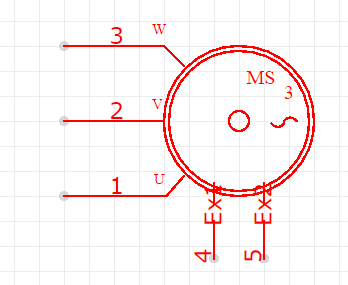

The selsyn has a design similar to a motor with a three-phase stator winding, and a single-phase rotor winding. The Selsyn has three terminals connected to the star-connected stator winding and two terminals connected to the rotor winding. The current to the rotor is fed through rings and brushes.

This is how you can imagine the rotor:

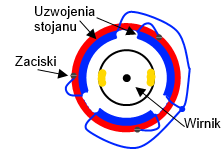

Now we create a three-phase star-connected winding around the rotor:

The coils are offset by 120°.

On the housing we still bring out the terminals that supply current to the rotor through the brushes:

.

.Schematically, we can represent our selsyn as follows:

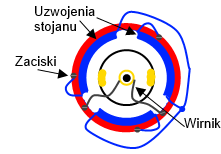

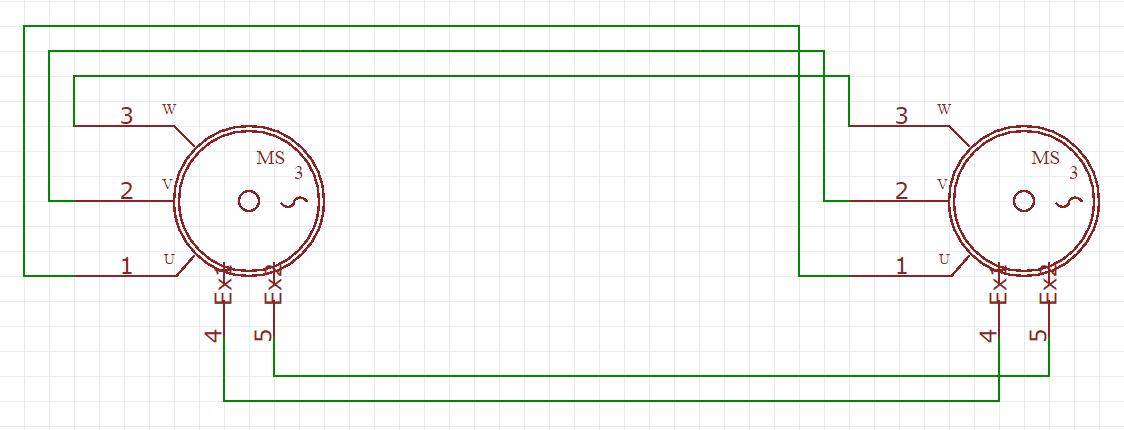

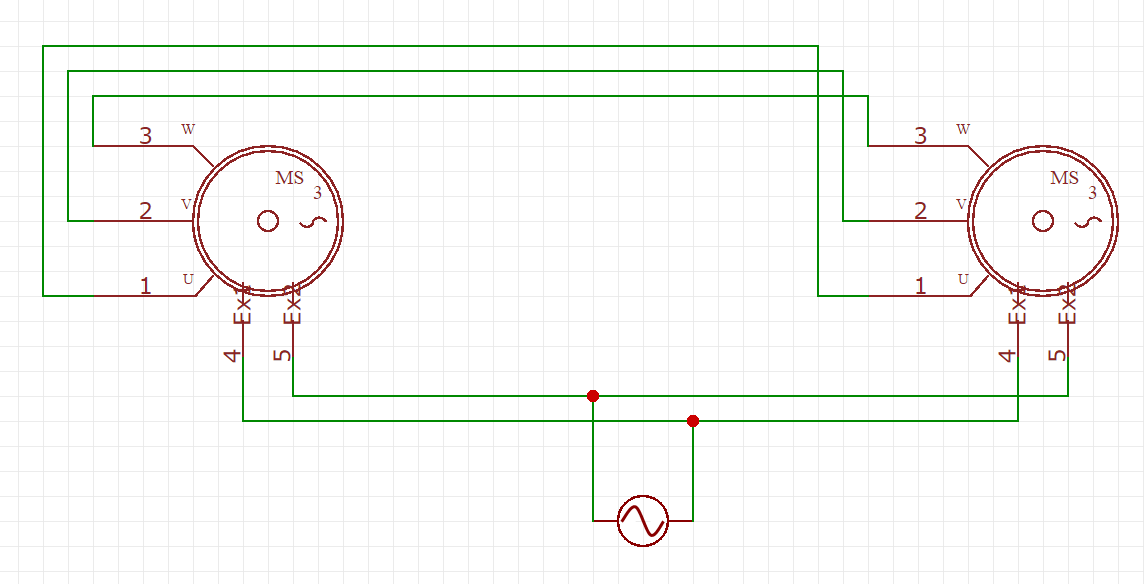

And now the most interesting thing, how do we connect the selsyns so that one mimics the movements of the other?

We need five wires. We connect the leads supplying the rotor windings in parallel (two wires). We connect each of the corresponding phases together (three wires).

In order for the devices to work, we supply AC power to the rotor windings:

The voltage of the selsyn power supply varied, it could be 220V, 110V, 45V and many others, the frequency did not necessarily have to be 50Hz, a voltage of 400Hz was often used.

As you can easily imagine - in a selsyn link could work more units connected together, as a result, you could build a system with multiple indicators. In practical implementations, there were also windings and circuits (RC) to suppress vibrations. Selsyn could also have a single-phase stator and a three-phase rotor winding. There were solutions with a three-phase stator and rotor. Most of you probably noticed that the selsyn could be used as a mechanical phase shifter. The selsyn could be equipped with a gearbox, and could also be used to build a simple tracking control with a separate drive motor (something similar to today's model servo). The operation of the selsyn in practice is reviewed here : https://www.elektroda.pl/rtvforum/topic4001320.html

On YT you can find many videos showing the operation of selsyn, an example found demonstration of the operation:

Here we can see a set of evaluation set with selsyn

This is how it used to be -. using selsyn, it was possible to transmit information about the position of the axle using electrical connections.

Have you ever come across a device with a selsyn? .

Cool? Ranking DIY