Good afternoon, I am looking for a solution to the following issue.

I have a fan (DC) running in continuous mode. I would like to connect it to some kind of controller which, when negative temperature is detected, would switch it to power with a timer running 15 mins on, 15 mins off, and which would return to continuous operation when the temperature rises.

The idea is to achieve this effect: when the outside temperature is positive, the fan runs continuously, when it is negative it runs in 15 min on/off mode.

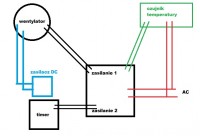

I wanted to do this with a temperature controller , timer and automatic power regulator , which would switch to an alternate power supply with a timer after a loss of voltage from the temperature controller, but maybe there is a simpler way, because here I have as many as three devices?

I have a fan (DC) running in continuous mode. I would like to connect it to some kind of controller which, when negative temperature is detected, would switch it to power with a timer running 15 mins on, 15 mins off, and which would return to continuous operation when the temperature rises.

The idea is to achieve this effect: when the outside temperature is positive, the fan runs continuously, when it is negative it runs in 15 min on/off mode.

I wanted to do this with a temperature controller , timer and automatic power regulator , which would switch to an alternate power supply with a timer after a loss of voltage from the temperature controller, but maybe there is a simpler way, because here I have as many as three devices?