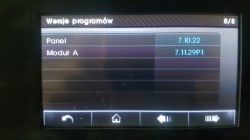

It is soft. Unfortunately, only service technicians have it. At the beginning of the year, I had a service technician. The program itself is available, not even hard, but harder with the soft itself. It is loaded through this program, the module is then connected via USB to the computer. You can also do it in such a way that the flash drive is loaded with soft and from the level of the device (panel) itself, you can update it. The manual provides for this. Unfortunately, my service technician is like saying "very mysterious" and does not really want to share. If I asked someone else, maybe he would give these binaries.

I will start writing a parser for the data taken from this port. I will probably do python, but I will think about it.

Of course, I will share the information and this script. I still want to drop it for RRD, because I care about the charts.

I will start writing a parser for the data taken from this port. I will probably do python, but I will think about it.

Of course, I will share the information and this script. I still want to drop it for RRD, because I care about the charts.