przemo_ns wrote: I wonder if it only gives the temperature to the controller or keeps the set temperature in the apartment at home and sends stop and start commands in order to achieve the temperature in the room by the stove, but I bet that it only measures the temperature and gives it to the controller. I would be interested in the log as the temp of the touch panel increases from below to above the set room.

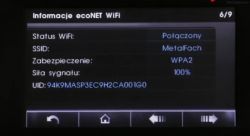

The stove controller can choose from (in my case) 3 operating modes: two are built into the controller and the third one is ecoTouch. Then "ecoTouch" supposedly becomes his "eyes". It can work in some modes (winter, summer, schedule, comfort, domestic hot water heating, house ventilation, etc.). In this mode, in which the control is based on the set temperature in the house, it works in such a way that the ecoTouch itself measures the temperature itself. If it falls below the set value, it starts the furnace. If the temperature in the house is higher, the stove is stopped. There is a hysteresis for this, for example 1C, so if it is 19.5 at home and the ecoTouch setting is to be 20C, it will not start the stove. In this operating mode, ecoTouch practically commands what the controller should do. In my opinion, the action logic is here, and ecoTouch only "triggers" the start. Of course, the stove controller has its settings for maximum temperatures and probably if there was no heat reception, and ecoTouch would indicate that it is too cold, the stove will end up idle (it will reach the set boiler temperature + hysteresis). So if I have a hysteresis on the 5C boiler, the boiler temperature is set to 53C, when it reaches 58C and there is no heat reception, it will start the putting out procedure. Then it will wait for the boiler temperature to drop to 48C (53C - 5C hysteresis) and then fire it up again. If, of course, ecoToch keeps saying it's too cold. If not, then the stove will simply stand (and here, if there is no supervision - it will light it there from time to time) or if it has the DHW additional heating mode on, then if the temperature dropped there, then it would also fire the boiler, but after it is only to heat up the DHW.

In general, the logic is extensive here and it all depends on what is installed. I use ecoTouch mainly as a home stove control. I do not use temperature measurement, because the room with this panel is not a good place. I have a relatively stable temperature in this room and the radiators are almost closed. And it would be cold in another part of the house.

I don't know if you want, I can switch to ecoTouch mode and then you would see, but I need to have a little more time.

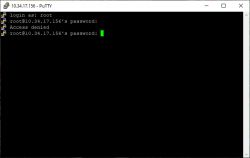

I will add that STX 0x68 is sometimes not a good choice. You have to look for STX + frame length and CRC and then decode everything.

Yesterday I had a situation where he suddenly stopped drawing charts. It turned out that the data matched that the first two hexes occurred somewhere in the string, and the parser was taking the wrong starting point. I reworked the script a bit, but I will follow my colleague's track, who did it nicer (mine was mainly POC) so that the charts were drawn to me and the code did not offend with its length.

As for sending packages, I will also try to write something today in the evening and send it to the driver. We'll see.

Last but not least, I called a service technician in the area, but the wheel is very stiff. He did not want to give a batch, at most I can come update to do it. Maybe it would have been easier on the spot if he had been and deleted PLN 350, but I didn't have time to visit him and so I can't make an appointment with him.