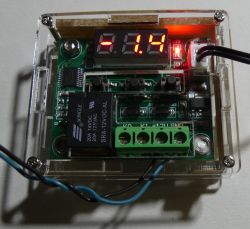

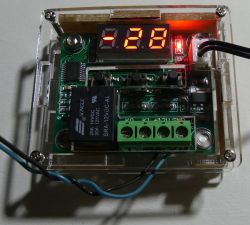

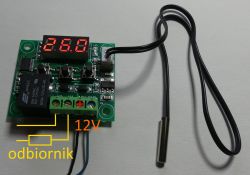

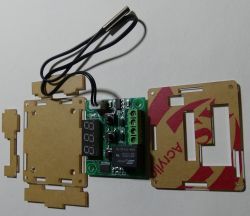

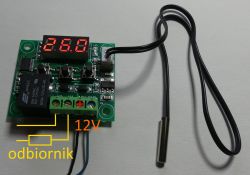

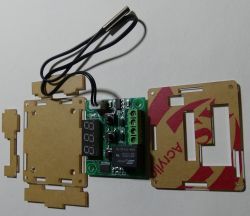

The W1209 thermostat can control a heating or cooling device. The LED display shows the current temperature with a resolution of 0.1C, measured with a sensor based on the NTC element. The simple menu of the system allows, among others, to define the type of controlled device, calibrate the thermometer readings, and determine the hysteresis range. The system is supplied with 12V and consumes ~ 16mA with the relay turned off, while the relay coil is powered, the current consumption increases to 65mA. Relay contacts, as described, can switch 20A at 14VDC and 20A at 125VAC. A plexiglass housing is included with the thermostat.

The W1209 thermostat will soon appear in the elektroda.pl gadgets.

To set the set temperature, shortly press the microswitch marked SET (the digits on the display will start blinking) and use the + - buttons to set the temperature to be stabilized by the thermostat. We can set the value from -50C to 110C.

Holding the SET button for longer than 5s displays the menu items from P0 to P6. Entering the settings of a certain menu level is done by pressing the SET button.

P0 - select the type of connected device:

H- a device generating heat, i.e. a heater, e.g. in the form of a resistor

C- cooling device, e.g. fan or Peltier module, C is the default setting

P1 - we set the hysteresis, i.e. the deliberate interval between switching on and switching off an element, by default they are 2C (0.1-15 adjustment),

e.g. in case of cooling and the thermostat temperature is set to 20C, cooling will be turned on after reaching 20C,

while cooling will be turned off at 18C (2C hysteresis). Setting the hysteresis will reduce the number of switchings of the relay, increasing the life of the contacts.

P2 and P3 - setting the maximum and minimum temperature (by default set to the maximum and minimum measurement, I do not know what is the practical application)

P4 - temperature sensor calibration -7C to 7C. A one-point calibration is debatable, but for the thermostat's setpoint temperature it may make sense.

P5 - delay time of switching on the relay.

P6 - extreme temperature alarm, when the temperature reading reaches the set alarm threshold, the relay will be turned off, the symbol --- will appear on the display. You can set this value to a temperature that is dangerous for the system, in an emergency the heater power supply will be turned off.

The NTC sensor is closed in a metal housing which increases its resistance to damage. When the sensor is disconnected, the thermostat displays LLL. Room temperature readings are the same as with a thermocouple multimeter.

Connecting the controlled receiver is very simple. The relay is connected in series in the receiver power supply circuit. We supply 12V DC to the thermostat.

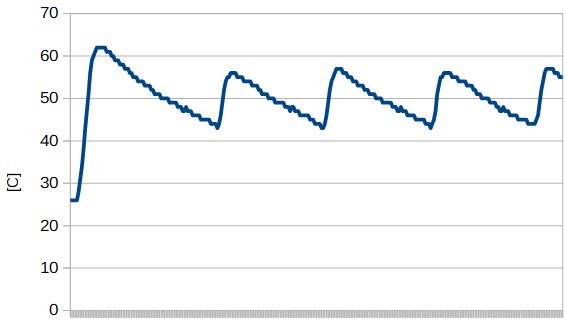

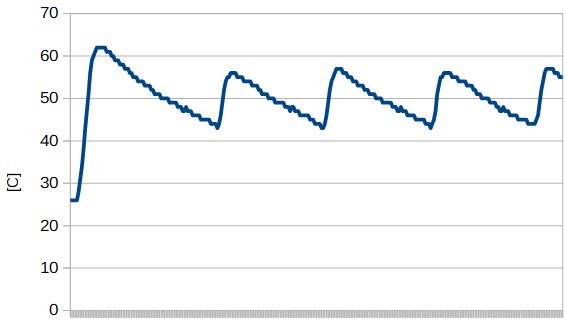

Let's make a test and use a 4.7om resistor powered from 12V as a heating element. Place the sensor so that it measures the heater temperature. At the same time, we can record the temperature of the resistor.

We set the thermostat to 45C and see how the on / off control is doing.

Considerable temperature fluctuations caused by the "inertia" of the system are visible. Around 45C you can see the moments of switching on the relay, but despite switching off the power supply to the resistor, the temperature rises for some time, then the temperature drops until the relay is switched on again. This example shows that the accuracy of the temperature sensor and measurement may not be of great importance in on / off control. Such simple control will prove itself in many applications. In more demanding applications, the heater can be controlled, for example, by PWM or phase, and even a PID controller as a controller.

In the set with the W1209 thermostat you will find a plexiglass housing.

Where do you see the applications for the W1209 thermostat?

The W1209 thermostat will soon appear in the elektroda.pl gadgets.

To set the set temperature, shortly press the microswitch marked SET (the digits on the display will start blinking) and use the + - buttons to set the temperature to be stabilized by the thermostat. We can set the value from -50C to 110C.

Holding the SET button for longer than 5s displays the menu items from P0 to P6. Entering the settings of a certain menu level is done by pressing the SET button.

P0 - select the type of connected device:

H- a device generating heat, i.e. a heater, e.g. in the form of a resistor

C- cooling device, e.g. fan or Peltier module, C is the default setting

P1 - we set the hysteresis, i.e. the deliberate interval between switching on and switching off an element, by default they are 2C (0.1-15 adjustment),

e.g. in case of cooling and the thermostat temperature is set to 20C, cooling will be turned on after reaching 20C,

while cooling will be turned off at 18C (2C hysteresis). Setting the hysteresis will reduce the number of switchings of the relay, increasing the life of the contacts.

P2 and P3 - setting the maximum and minimum temperature (by default set to the maximum and minimum measurement, I do not know what is the practical application)

P4 - temperature sensor calibration -7C to 7C. A one-point calibration is debatable, but for the thermostat's setpoint temperature it may make sense.

P5 - delay time of switching on the relay.

P6 - extreme temperature alarm, when the temperature reading reaches the set alarm threshold, the relay will be turned off, the symbol --- will appear on the display. You can set this value to a temperature that is dangerous for the system, in an emergency the heater power supply will be turned off.

The NTC sensor is closed in a metal housing which increases its resistance to damage. When the sensor is disconnected, the thermostat displays LLL. Room temperature readings are the same as with a thermocouple multimeter.

Connecting the controlled receiver is very simple. The relay is connected in series in the receiver power supply circuit. We supply 12V DC to the thermostat.

Let's make a test and use a 4.7om resistor powered from 12V as a heating element. Place the sensor so that it measures the heater temperature. At the same time, we can record the temperature of the resistor.

We set the thermostat to 45C and see how the on / off control is doing.

Considerable temperature fluctuations caused by the "inertia" of the system are visible. Around 45C you can see the moments of switching on the relay, but despite switching off the power supply to the resistor, the temperature rises for some time, then the temperature drops until the relay is switched on again. This example shows that the accuracy of the temperature sensor and measurement may not be of great importance in on / off control. Such simple control will prove itself in many applications. In more demanding applications, the heater can be controlled, for example, by PWM or phase, and even a PID controller as a controller.

In the set with the W1209 thermostat you will find a plexiglass housing.

Where do you see the applications for the W1209 thermostat?

Cool? Ranking DIY