Welcome.

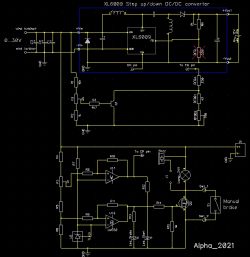

I would like to present you a simple controller for charging batteries from a small wind turbine, using a ready-made up / down converter module on the XL6009 chip.

However, I must start with the fact that I have dreamed of having a small wind turbine for a long time. And although reading many statements on the Internet convinced that they do not meet the hopes placed in them, I was already determined to order something cheap on the Polish or Chinese auction portal and check it for myself.

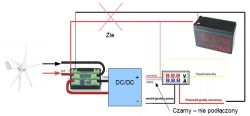

The turbine was to support a small solar system that charges 12V batteries and powers various crap

Fortunately, at the last minute there was an opportunity to buy a used brand Rutland 910 turbine, which I used.

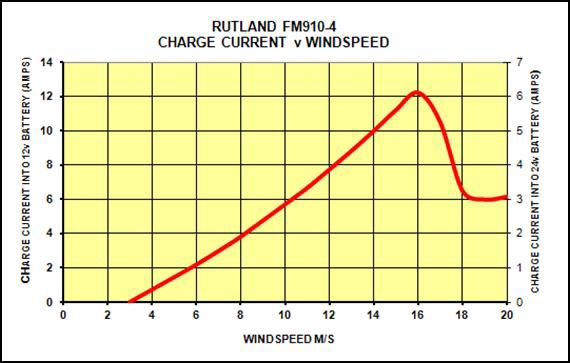

Its parameters are:

- rotor diameter 91cm

-6 shovels

- maximum power 80W

-weight about 15 kg

From myself I can add good balance, quiet operation and low rotation resistance.

The windmill was mounted on the top of the building, about 10m above the ground.

Behind the building there is a forest wall, and the plot is located in a fairly large depression, but the windmill starts up surprisingly eagerly even with slight gusts of wind.

However, concerns have been confirmed that the amount of voltage generated during the vast majority of operating time is too low to be used directly. Even - subjectively perceived - quite fast rotation of the blades, generated the output voltage in the range of 7..9V. Higher tension was extremely rare.

However, I wanted to use at least some of the energy that is generated and hence the idea to use a converter that will increase or decrease the input voltage depending on the need.

The structure was to be simple and made of easily accessible elements.

I decided to use one of the ready-made modules available in many variants on the Chinese website and after reviewing them, the choice fell on the XL6009 chip. It meets all my assumptions: input voltage 3.5V-32V, current up to 3A and - what is very important - Enable input, which allows you to turn the inverter on and off.

You can also use the module with the XL6019 chip, which has an additional soft-start function, but its efficiency is only 1.5A.

However, converters with the LM2577 system are not suitable, because they do not have the Enable input mentioned above.

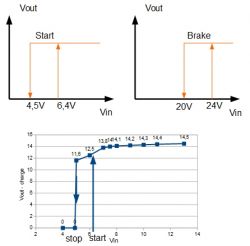

It was only necessary to add a system that would activate the converter so that it would operate in a safe voltage range (above Umin.) And would not choke the turbine's rotation. The large capacitances of the capacitors at the input were to extend the converter operation cycles. The output voltage of the XL6009 was set to 14.5V.

A system for detecting too high input voltage was also created immediately, which switched on the braking load in the form of a 50W bulb.

And although the system worked and had considerable desulfating properties (

So I decided to make the output voltage from the converter dependent on the input voltage stored in the capacitors.

This role is performed by one transistor that connects the feedback voltage wthe converter system: each increase in the input voltage causes a stronger control of the transistor, short-circuit of the RFB resistor, lowering the voltage at the FB XL6009 terminal, and thus increasing the output voltage by the converter, which aims to reach 1.25V at the FB terminal.

As a result, the current flowing to the batteries increases with the speed of the wind blowing

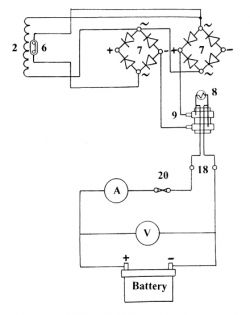

Scheme and diagram of comparators and converter operation:

Item values are not critical and can be changed as needed.

The small-signal NPN transistor used, with beta> 200, and the Mosfet-N with low parameters (200V, 0.3ohm), which I would not use anywhere else.

My input capacitor bank has a total capacity of approx. 50mF, but it can be reduced.

The maximum input voltage determines the applied LM324 and XL6009 and amounts to 32V.

I used two panel meters to visualize the parameters. A small note here: the Atorch 150V / 8A measuring combine used cannot be powered as shown in the diagram below, because part of the output current flows directly to the battery that supplies it, thus falsifying (lowering) the measurement made with the U / I meter.

The adjustment is best done by connecting the system to a regulated power supply.

Set the voltage> 15V on the power supply, turn P2 fully to the left (to maximally drive the Q1 transistor base) and set the P1 multiturn potentiometer on the converter to the output voltage of 14.5-14.7V (max charging voltage, at your discretion). Reduce the supply voltage to the minimum, at which the converter does not turn off yet (about 6V), turn P2 to the right maximum, and P4 (Rfb2) set the voltage from which the converter will start to charge the battery after starting (less than 12V for me). Increase the supply voltage again to the level at which we would like to obtain the full charging voltage (i.e. 14.5V) and turn the P2 potentiometer counterclockwise until this voltage is obtained at the output.

The P3 potentiometer can be used to set the thresholds at which the comparator will turn the converter on and off. The hysteresis is around 2V.

I packed the whole thing into a plastic housing that had already been used in a similar project. I am not a special esthete, so don't judge me in terms of how the whole thing is finished. The voltage is low here, the currents are low - this will not burn my house

When it blows, I will try to record a movie with the operation and indications of the meters.

Finally, I would like to write a few words about the real gains from such a windmill.

I do not have instruments for measuring wind speed, the location of the turbine is also very important, but during a windy day, when a person already feels a lot of discomfort during a walk, such a system, generating an average of about 2-5W, is able to cram about 11Ah into the batteries.

Let me remind you - 24 hours of strong wind. It doesn't knock it down, does it?

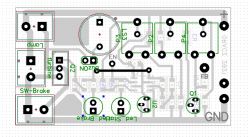

I enclose the diagram and the pattern of the board ready for printing (after minor corrections - including replacement of the Q1 housing from Sot-23 to TO-92, and additional holes for smaller potentiometers). Project made in Dip-Trace.

Cool? Ranking DIY