Hi, I'm planning to cheaply realise an automatic opening of the chicken coop and I don't know what to use for pulling/winding the cable connected to the door.

I was initially thinking of a weight or a tension spring, which would pull the door in the direction of opening and the door would be held in the closed position by the electric door opener. ESP + relay would trigger the electric door opener so that the door would open.

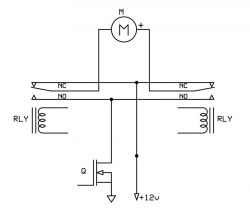

I am thinking, however, whether it would not be better, and certainly cheaper, to use a car wiper motor or windscreen wiper motor. These can be bought for £10, the question is whether they can be controlled in a 'simple' way. I found out that the wiper motor has a crank mechanism, so that with a long enough arm it would manage to open the door, and returning the arm to the start position should not be a problem if the door opens sideways or, in the case of the flap and guillotine, has some sort of latching mechanism.

The shaft motor would give the possibility to close the poultry house, but what about possible obstacles and motor overload?

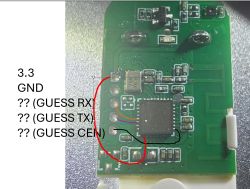

What about the control, I would like to stay with the ESP, because I still intend to use reed switches to verify if the poultry house is closed (sometimes it happens to forget if it is closed or not) and control the lighting.

I was initially thinking of a weight or a tension spring, which would pull the door in the direction of opening and the door would be held in the closed position by the electric door opener. ESP + relay would trigger the electric door opener so that the door would open.

I am thinking, however, whether it would not be better, and certainly cheaper, to use a car wiper motor or windscreen wiper motor. These can be bought for £10, the question is whether they can be controlled in a 'simple' way. I found out that the wiper motor has a crank mechanism, so that with a long enough arm it would manage to open the door, and returning the arm to the start position should not be a problem if the door opens sideways or, in the case of the flap and guillotine, has some sort of latching mechanism.

The shaft motor would give the possibility to close the poultry house, but what about possible obstacles and motor overload?

What about the control, I would like to stay with the ESP, because I still intend to use reed switches to verify if the poultry house is closed (sometimes it happens to forget if it is closed or not) and control the lighting.