With this adjustable pulse time it could work.

about the temperature, when I collect the data I'll send

Fast, because I'm angry, I broke the via when I pulled out the capacitor

they are missing 10% of the capacitance but it seems that it is not bad, one 4.7u/400V (low ESR), the other ordinary 470u/16V.

100u/25V soldered to Vcc CBU - it gave nothing

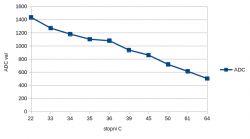

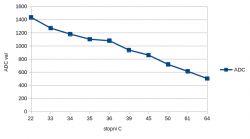

Temperature comes out linear, with the increase of its value, the value of ADC decreases, so rather will not be a problem to run it.

Tomorrow I'll upload tables with values and graph, and hopefully repair the via to run the contraption

I have the values from ADC in relation to temperature change.

stopnie C ADC

22 1437

33 1273

34 1182

35 1103

36 1081

39 939

45 862

50 720

61 614

64 504

#### as for restarts

With the pulse length there may be something to it, on the original Tuya there were no resets.

I soldered 2.2u/400V - still the same

I soldered 220u/35V - still the same

I unsoldered both capacitors

I started to measure the original ones: 4.3u and 415u - so-so

I soldered them back

then I switched pins

"24": "BridgeFWD;1",

"26": "BridgeREV;1"

on

"24": "Rel;1",

"26": "Rel_n;1"

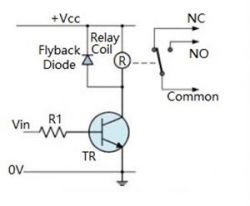

the relay started to be powered all the time , not just at the moment of switching

the power supply became loaded in continuous mode, I had a pyrometer and thermocouple at hand

I measured the 470u/16v capacitor in the configuration for bridge operation had about 30 deg.C

with the relay continuously energised, after a few minutes of lying around and my deliberation it warmed up to 50 deg.C and voilà

interesting fact I soldered 220u to it and the device continued to make resets when switching on the relay, I threw it out completely because I found that it has a small internal resistance, I had 2x220u on hand, which I soldered briefly and the restarts stopped

now I'm waiting for a new capacitor, unfortunately it must be fi8 x 8mm high

if I manage to do something with this temperature reading after the ADC , then it will be possible to make a template