This is my teardown of EARU EAWCPT-J relay.

35mm Din Rail WIFI Smart Switch Remote control byTuya APP for Smart home from https://fr.aliexpress.com/item/1005005903760507.html

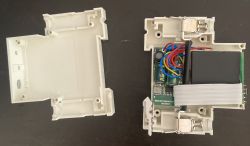

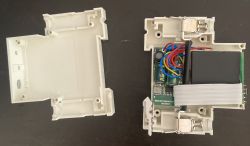

First, drill the 6 holding "screws" and push them through. And split the shields.

WC1H - BL0942 - CBU :

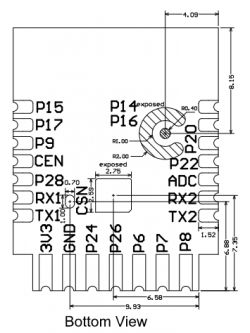

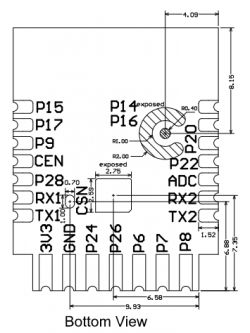

From CBU pins :

Soldered to RX1, TX1, 3V3 and GND and connected to FTDI232 :

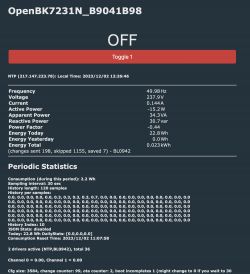

Reading only worked with 9600 baud rate :

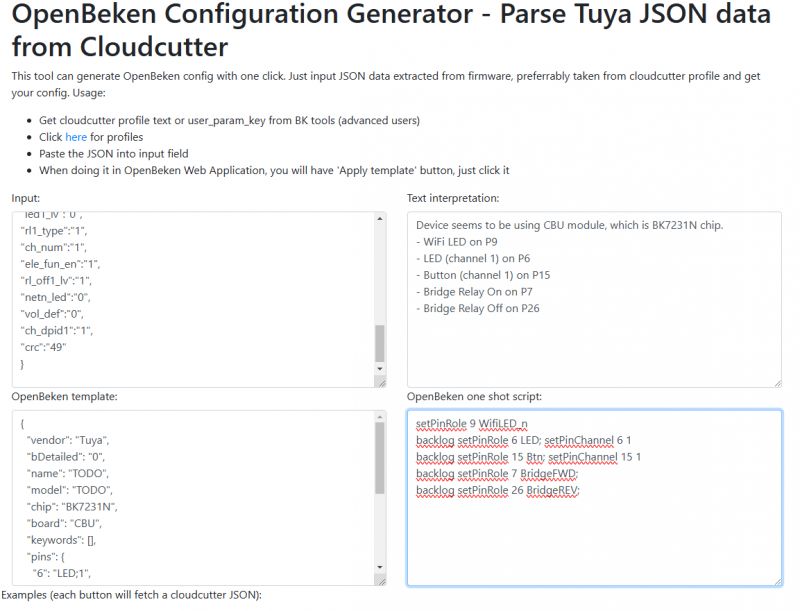

json and configuration extracted:

My current template:

Startup command:

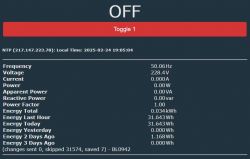

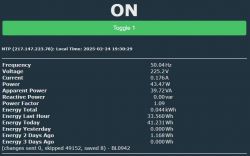

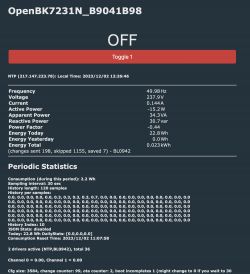

I then calibrated Voltage, Current and Power.

Just one issue, when relay is down, "Active Power" and "Power Factor" indicate negative value, even with Flag 38 checked.

Here is the original firmware backup:

35mm Din Rail WIFI Smart Switch Remote control byTuya APP for Smart home from https://fr.aliexpress.com/item/1005005903760507.html

First, drill the 6 holding "screws" and push them through. And split the shields.

WC1H - BL0942 - CBU :

From CBU pins :

Soldered to RX1, TX1, 3V3 and GND and connected to FTDI232 :

Reading only worked with 9600 baud rate :

json and configuration extracted:

Code: JSON

Code: Text

My current template:

Code: JSON

Startup command:

Code: Text

I then calibrated Voltage, Current and Power.

Just one issue, when relay is down, "Active Power" and "Power Factor" indicate negative value, even with Flag 38 checked.

Here is the original firmware backup:

Cool? Ranking DIY