I invite you to a short practical test of the YIHUA 926 LED II 120W soldering station, purchased for approximately PLN 180. I will check here how it is doing, among others. with DIP soldering, soldering components from the computer motherboard, and I will also try to present some of the experiments in the form of short films. I invite.

Purchase and contents of the set

The price is about PLN 180 in our country, it could probably be cheaper from China, but we didn`t want to mess around. Here is the box I received:

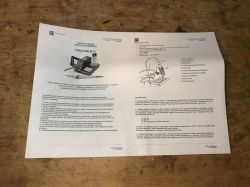

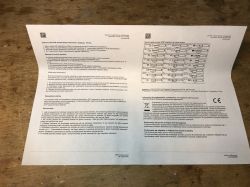

Instructions (I will not repeat the information, please enlarge the photos):

And the contents of the set - pretty much everything you need is:

The display is a classic 7-segment LED, of course it is readable, and there is also a switch for two temperature modes (see photo):

Replacing tips:

900M tips fit here, the same ones used in the cheapest soldering irons from China.

THT soldering

To test, let`s solder the DIP40 sockets to the board. We will use Sn60Pb40 filler metal and AGT-037 soldering paste.

The flux is not very evenly distributed, but let`s treat it as a plus because you can see what effect it has on soldering:

First - temperature 300°C:

Then - temperature 340°C:

Soldering is simple and pleasant, I was a bit better at higher temperatures. Another barrier was the restriction of movement by the camera tripod.

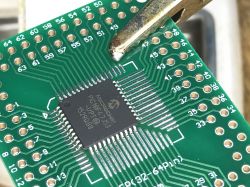

TQFP soldering

I solder TQFP with a regular tip, although a mini-wave tip would probably be better. My soldering method is "on foot", I grab one and the other corner of the system and then I try to solder the remaining legs using the "drag soldering" method. Dragging the tip over the legs of the system spreads the binder, and I can remove the excess with a braided line.

I know there are other, perhaps better, methods, but when soldering on such a small scale as I do, I didn`t need to try them.

On-site layout:

Caught legs:

A little fun (it`s a bit hard for me to solder with a big tripod and a phone in front of me) and then soldering a few legs, you can see how the binder melts and catches:

Here the soldering is shown a little better, you can see how the filler "goes" along the legs to the corner behind the tip, and then I remove its excess with a braid:

Basically the same as before, different approach:

And here I used the exposed paths of the breadboard and didn`t even have to remove excess binder:

Output from the motherboard

The covered desoldering method is:

1. applying flux to February

2. adding lead binder to mix with the solders

3. heating

First, maybe something simple - a battery basket:

Now for something more difficult, capacitors, and those on the large ground spout that act as a heat sink. I set the temperature to 450°C, out of curiosity to see how well it would work:

There was no problem - I also cleaned the holes:

Outlet from the motherboard 2 - USB connector

Maybe it`s something even more difficult. Let`s desolder these characteristic double/triple USB connectors. Here are his legs:

Added lead binder:

A moment of heating...

With a little help the connector comes out of the board:

Now it`s time to clean the holes with braid : :

It heats beautifully, after a while of heating the binder flows out of the holes into the braid, very satisfying.

Summary

Some time ago I reviewed the "younger brother" of this soldering iron, the cheapest "flask" 60W for PLN 25:

Cheap soldering iron with temperature control (UYUE 301D/APD931/BT136S)

It served me faithfully and was sufficient for most applications, even for TQFP soldering, so I can`t say that switching to YIHUA 926 LED II 120W if we only solder DIY structures as a hobby, it is a must. Cheaper models also work well.

It`s different when we want to desolder - outlet from the computer`s motherboard YIHUA 926 LED II 120W it`s pure pleasure. Cleaning the holes is the same. The binder goes right into the braid. I have the impression that maybe I set the temperature too high, but I wanted to see what this small soldering iron can do. Another thing is that I could have used a better flux... but the soldering was successful, capacitors in old computers can be replaced, and so can the connectors.

Finally, it is worth warning against low-quality 900M tips. I bought some of them at a bargain price in China and was very disappointed with their low durability, but this has already been discussed on the forum.

That`s it from me for now - maybe later I will try to do some additional temperature measurement test or review the inside of this soldering iron, but that`s enough for now. Has anyone used this station and if so, what were your impressions? Or maybe you know a better alternative in this budget?

Cool? Ranking DIY Helpful post? Buy me a coffee.