.

.

Today I'm testing a classic, budget 858 hot air soldering iron possible to buy for as little as £25-30 often appearing under different versions and names, such as DexXer 700W, or 858D, 858A, etc. I will check if this station is able to solder components from the motherboard at different temperatures and try to measure the resulting temperature at the nozzle output and present it on graphs.

This topic is sort of a continuation of my tests and measurements related to hot air, here the three previous parts:

Budget JCD 8908 2 in 1 soldering station (tips + hot air) for £200, VGA HDMI outlet etc .

Which hot air to buy? Comparison, measurements, graphs - JCD 8908, SP-1011DLR and QUICK 861DW

Comparison of QUICK 861DW and SUGON 8630 Pro hot air stations - 1kW vs 1.3kW heater

Test and measurements of the Preciva 995D 810W hot air soldering station - a good choice on a small budget? .

Here is some information from one of the sellers of this station, specifications:

.

.

Now let's look at the contents of the kit:

.

.

Here we have three basic nozzles with diameters of 3.5mm, 6.5mm and 9mm:

.

.

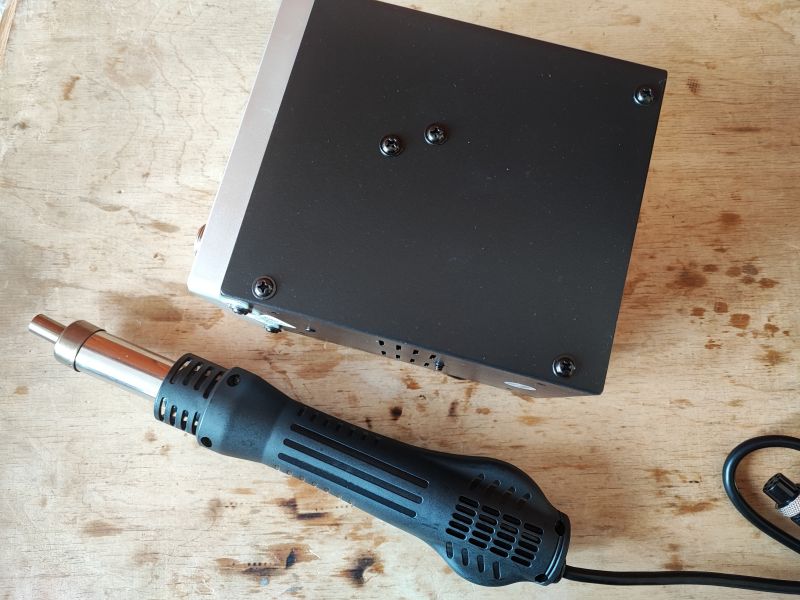

And, of course, the station - zero extra bits:

.

.

There is also a flask carrier (I didn't take a photo).

700W, 5A fuse:

.

.

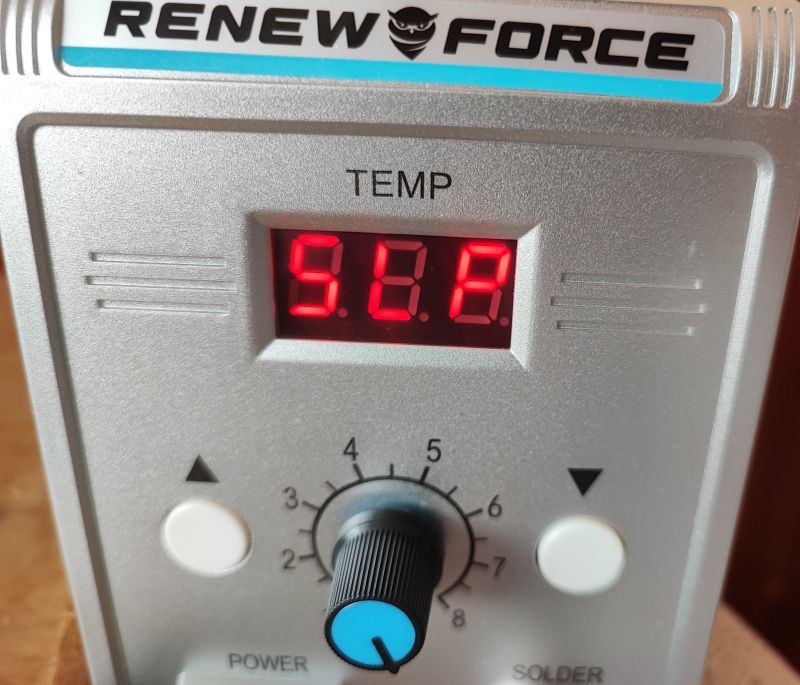

For blowing we have a classic potentiometer, for temperature control we have a 7-segment red display:

.

.

The sleep (detection of the station put down) is realised by a sensor based on the tilt of the flask:

.

.

So it's time to move on to testing, but first....

Organisational matters

Before we move on to the actual tests, I would like to highlight a few things here:

- all tests were performed on discs made from electro-waste

- the video clips do not show the correct methods of desoldering

- therefore in the videos I do not use kapton tape to protect adjacent components

- I do not ensure that the component does not "fly away" when blown by hot air

- the boards on the videos may not be thoroughly washed of flux

- in the videos I am "impatient" and move parts that should be left alone during the casting process, because if we use force we may break the pads

- etc. etc.

The topic "how to replace the MOSFET correctly and wash the board" will be covered separately. Here I am just testing hot air.

Videotests 858 .

Time for some experiments. For all the videos below I have made the following assumptions:

- at the beginning of the video the station is switched off, it is completely cooled down to room temperature, the board similarly

- 8.4mm nozzle or no nozzle (you can see in the video; yes, that's my nozzle, not any from this kit)

- highest blow rate, if the specifications are to be believed, 120l/m

- films are not processed

Let's start with lower temperatures. 350°C, full blow, TV motherboard:

Not bad, some memory or other chip in an SO8 can be removed in a minute.

400°C, full blow, laptop motherboard:

Here too it went in a minute, it probably would have soldered on a lower temperature too (but a bit slower), even though it's a laptop board, multilayered, with copper spouts, not bad heat pick-up.

400°C, full blow, computer motherboard:

Also a minute, not bad, although it's from the edge of the motherboard, I'll try something harder soon.

450°C, full blow, computer motherboard:

Not bad, takes the MOSFET off beautifully and that's from a large copper spout.

450°C, full blow, computer motherboard:

Not bad, takes off the MOSFET beautifully and that from a large copper spout.

450°C, full blow, laptop motherboard:

Drawings .

Such games of soldering a component out of scrap in time may be fun, but it's also better to measure something. The standard assumption here is to use the highest blowing, although in many cases it could be reduced (then it could also heat a bit harder), but that's the assumption I started with and it's hard to change anymore.

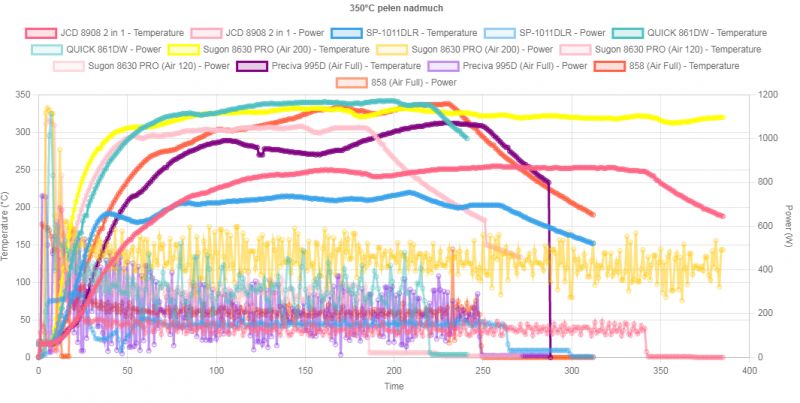

First a graph at 350°C:

.

.

Interactive version:

https://openshwprojects.github.io/hotair/version4/350c.html

However, the feedback that the 858 is a classic and doesn't do badly was true. It even beats the Preciva station here, and interestingly enough, both of these stations claim 120l/m blowing at full setting, but I have not verified this.

Of course, heating up is about three times slower than in stations 10 times more expensive anyway, but does it make a difference to a beginner?

Now the graph at 450°C:

.

.

Interactive version of the graph:

https://openshwprojects.github.io/hotair/version4/450c.html

Here, however, the station does not beat the 2-3 times more expensive Preciva station. Initially it heats up faster, but then it lacks power. I recorded a maximum of around 380°C. The Preciva reached about 30 degrees more.

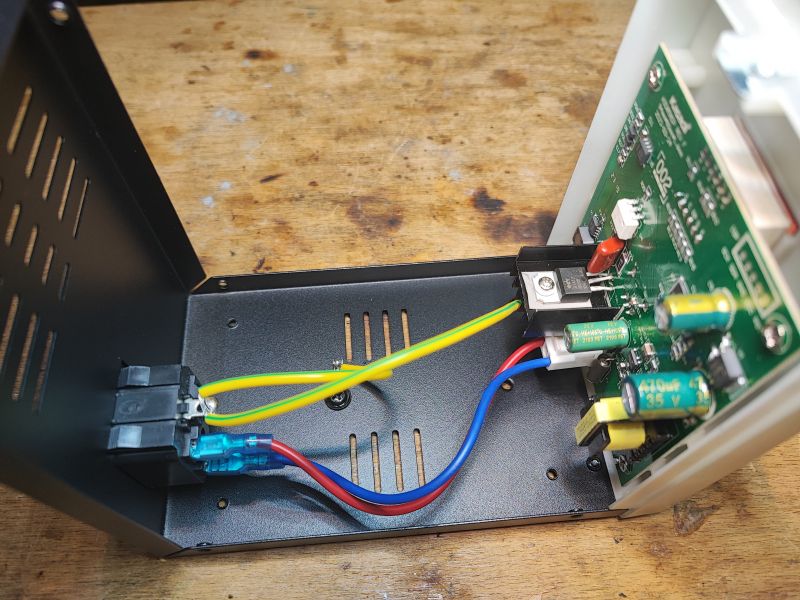

Interior 858 .

We remove the lid. Surprisingly there is a lot of free space inside, in fact the housing could be much smaller:

.

.

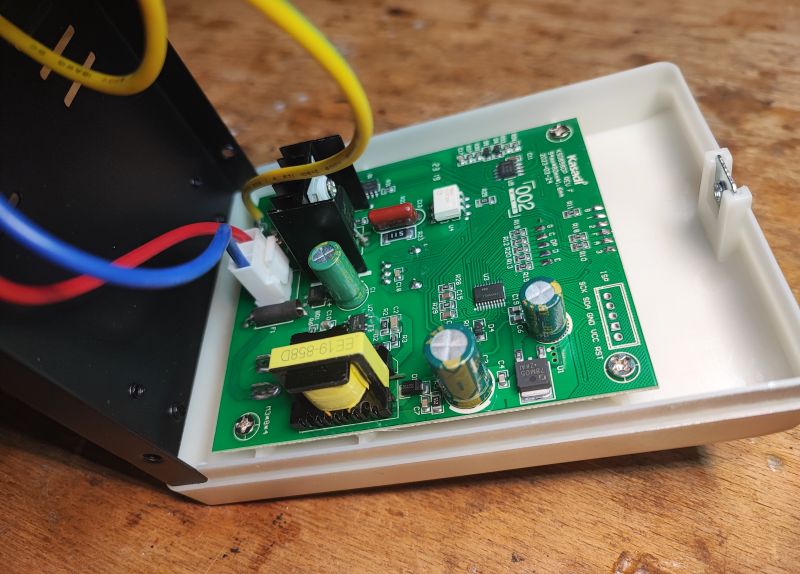

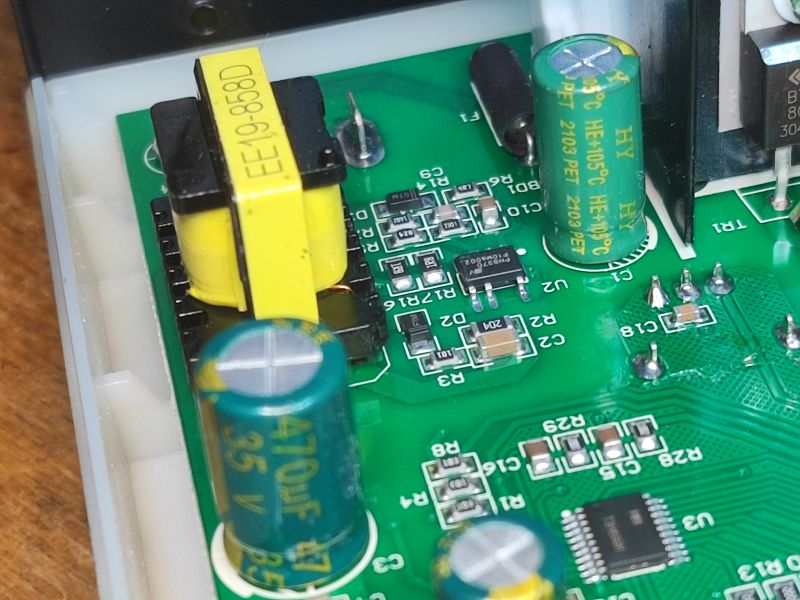

The PCB on the front panel contains everything you need - the power supply is there too, a tiny flyback of course:

.

.

Connector with SDA, SCK and RST and power supply - could it be for programming? Via I2C something?

.

.

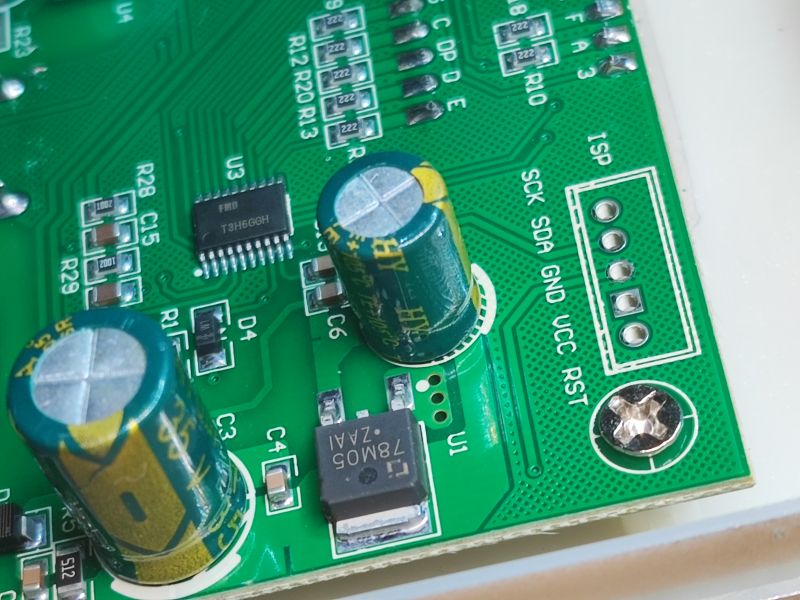

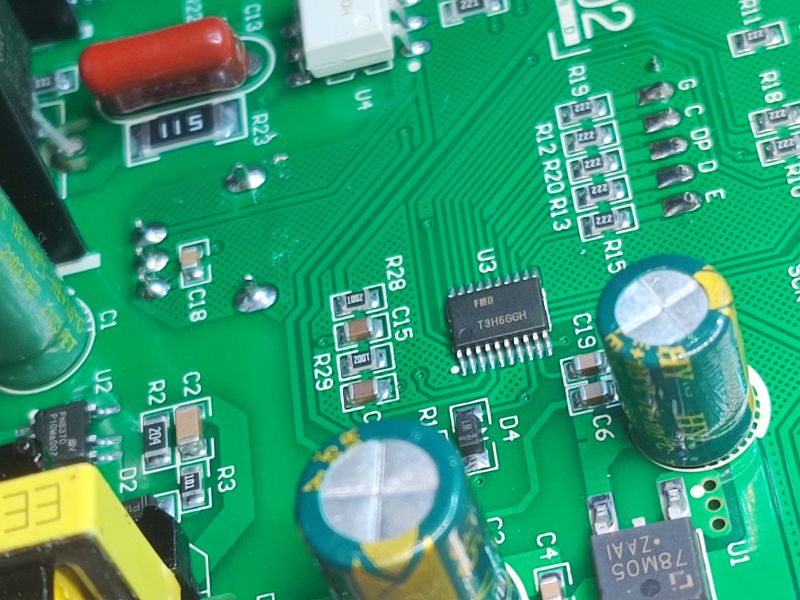

I think the main MCU is the FMD T3H6GGH:

.

.

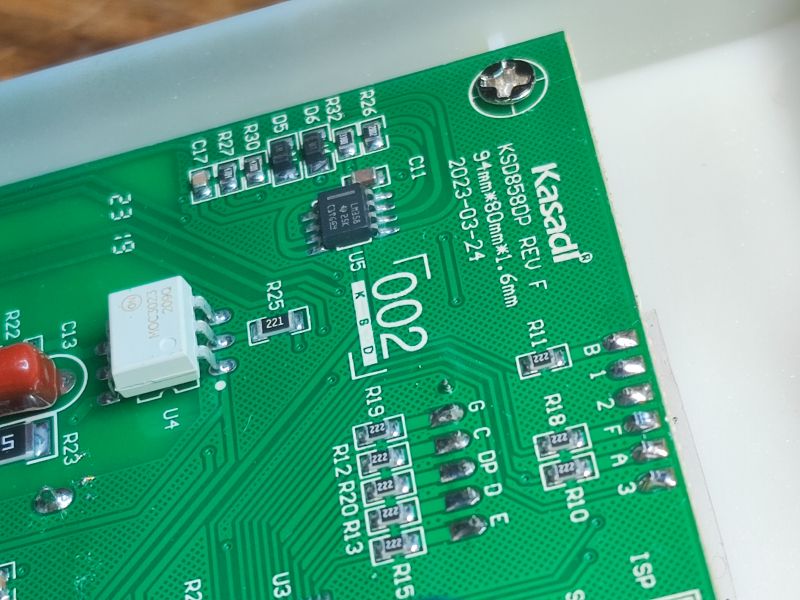

PCB designation:

Kasadi

KSD858DP REV F

2023-03-24

.

.

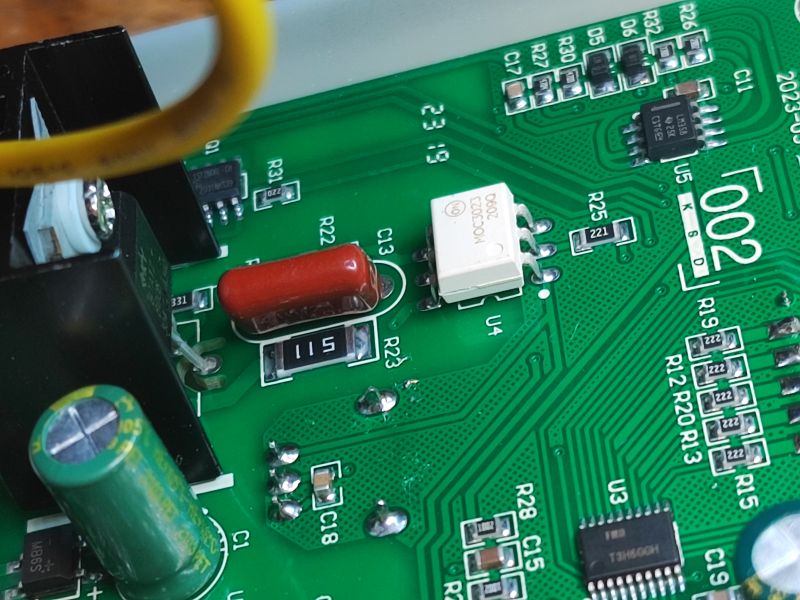

Executive part, optotriac MOC3023:

.

.

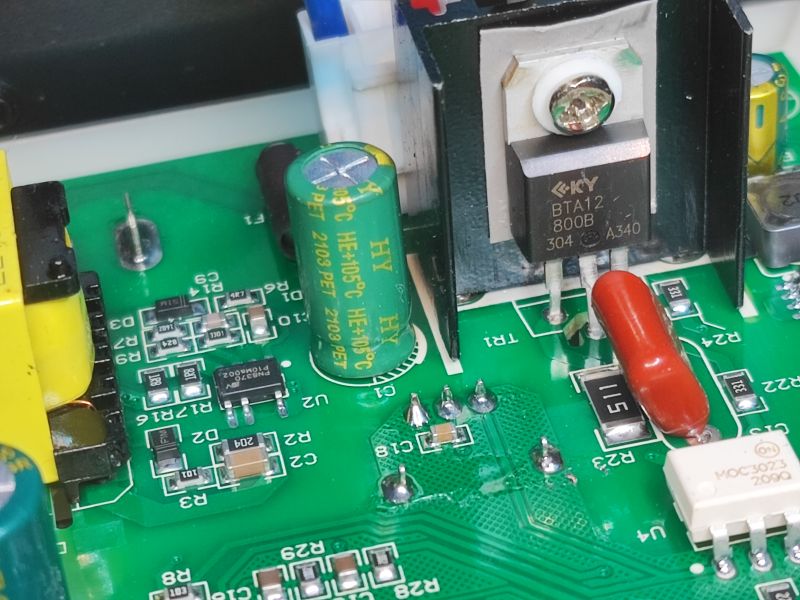

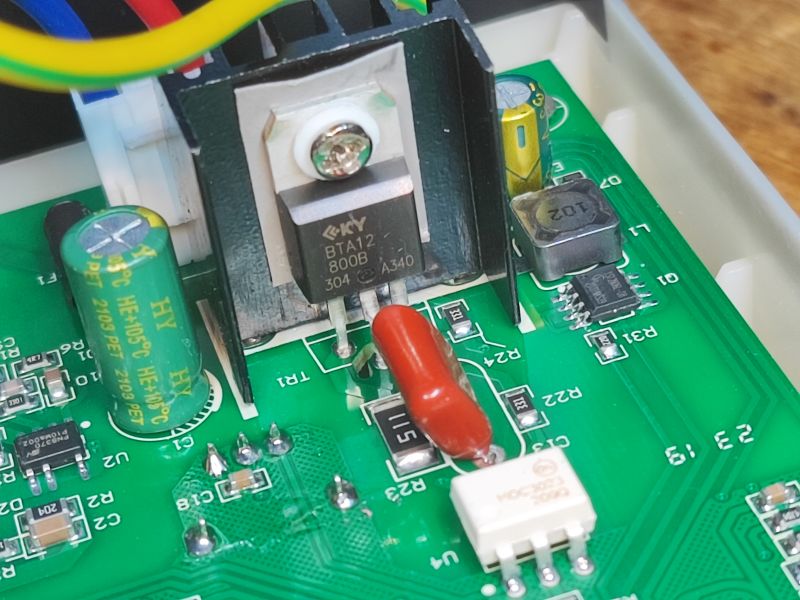

This optotriac in turn controls the BTA12 800B:

.

.

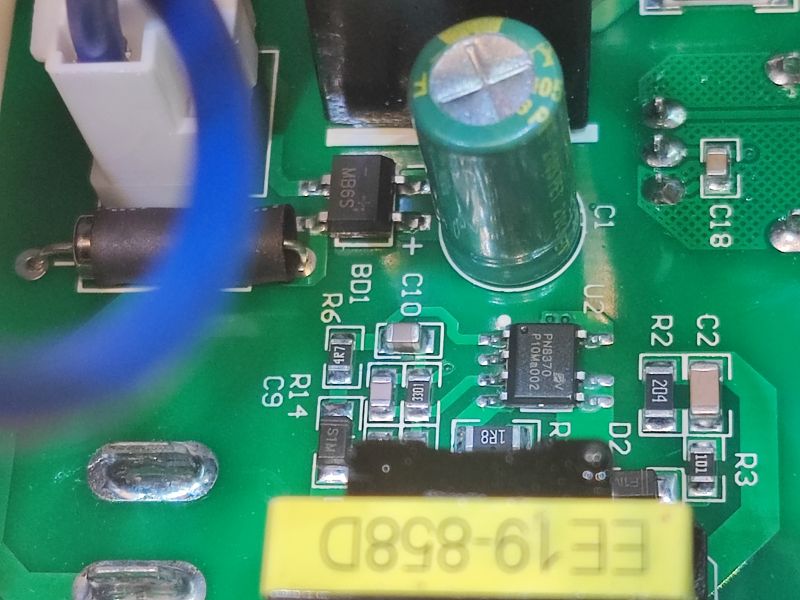

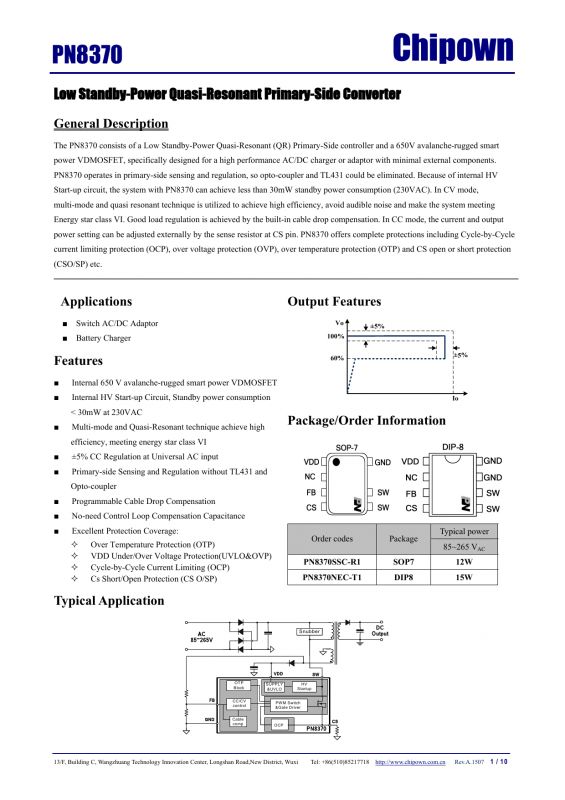

And the aforementioned power supply - it is based on the PN8370:

.

.

Some information about the PN8370, including an overview diagram of such an inverter:

.

.

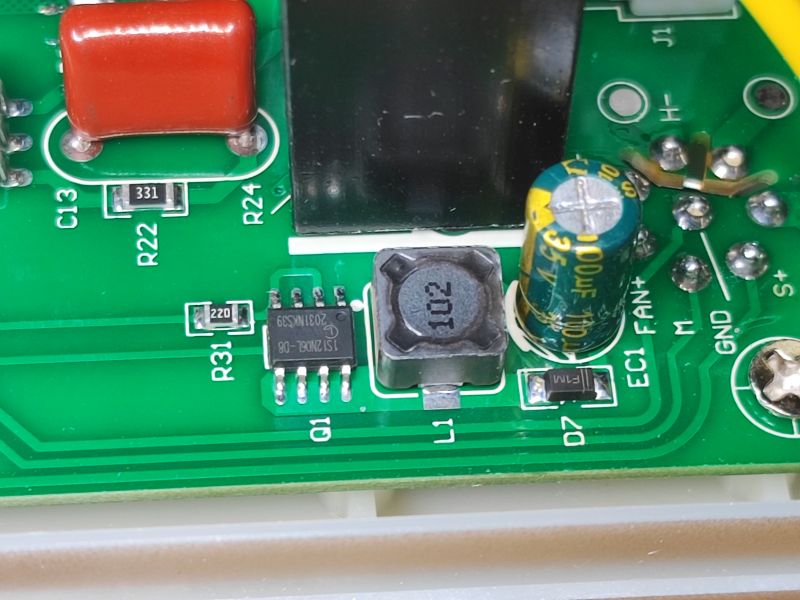

I spotted some more circuitry on board which I first thought was an inverter, but it looks like it's a 1S12N06L-D8 MOSFET, maybe an air supply control?

.

.

A truly modest and economical build.

Summary .

With the test criteria I have adopted, this station performs really well. It beats neither the Quick nor the Sugon, but after all, these two stations are practically 10 times more expensive than it! Last time I saw them, they were about £1,400 each, and the one in the topic can be got for about £140. In addition, this station performs much better than my JCD, with which, even after trying with reduced blowing, it was difficult to remove the component from the laptop motherboard without a heater. This station is also better at lower temperatures than the more expensive Preciva, while at higher temperatures it does not heat as much, and all this at (if I trust the manufacturer) a similar blowing setting (120l/m).

At the moment, my subjective feeling is that this is the best "budget" station for a beginner. It definitely beats e.g. the JCD, where I had problems with heating even with smaller blowing volumes....

A final small note - I am aware that my test does not examine the actual blowing power. I simply have no way of measuring it, so in my graphs I rely on what the station's manual states. So far, the declared strongest airflows agree, so there is apparently something to compare on the graph, but in practice I don't know how reliable this is. In addition, I pursued this topic some time ago and am only publishing it now, so I no longer have what to do with it... .

And which hot air station do you guys use? It would be easier for me to get started if I had an 858 straight away and not the flimsy (even at low blow) JCD.

Cool? Ranking DIY Helpful post? Buy me a coffee.