.

.

Is the Yato YT-82457 750W hot air soldering station capable of desoldering components from a computer motherboard? Is its performance comparable to that of more expensive stations available for 100-250$? How is such a station constructed inside? I will try to check this here and present the results in the form of videos and graphs.

This is going to be another hot air test by me, I recommend reading the previous tests:

Hot air station 858 for 150 zł (35$ or so) - what cheap hot air to fly out of laptop boards, computer? .

Budget soldering station JCD 8908 2 in 1 (soldering tips + hot air) for 200 zł (50$), VGA HDMI soldering etc

Which hot air to buy? Comparison, measurements, graphs - JCD 8908, SP-1011DLR and QUICK 861DW

Comparison of QUICK 861DW and SUGON 8630 Pro hot air stations - 1kW vs 1.3kW heater

Test and measurements of the Preciva 995D 810W hot air soldering station - a good choice on a small budget? .

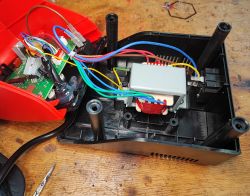

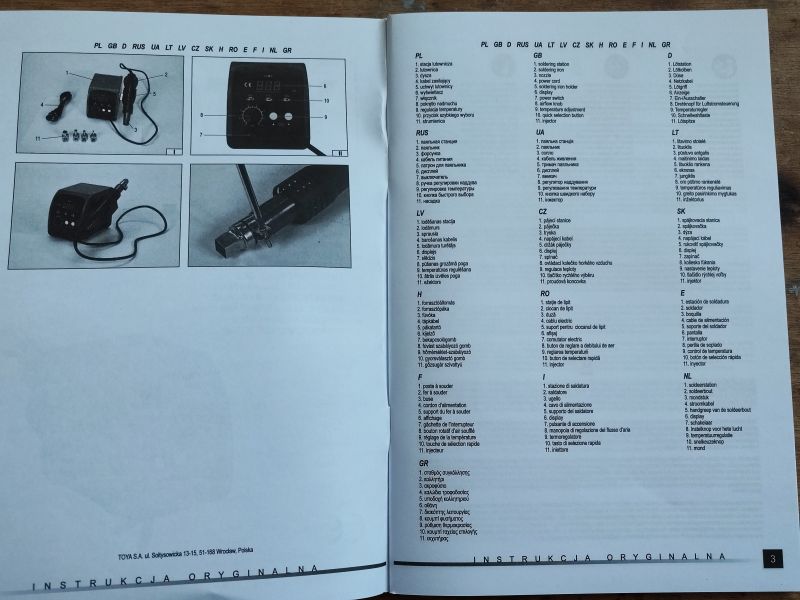

We start as usual with a presentation of the packaging and kit:

.

.

Maximum air flow power is as usual 120l/min, similar to the other stations. I think of those I have tested so far only the Sugon 8630 PRO offered 200l/min.

The kit comes with instructions and additional nozzles:

.

.

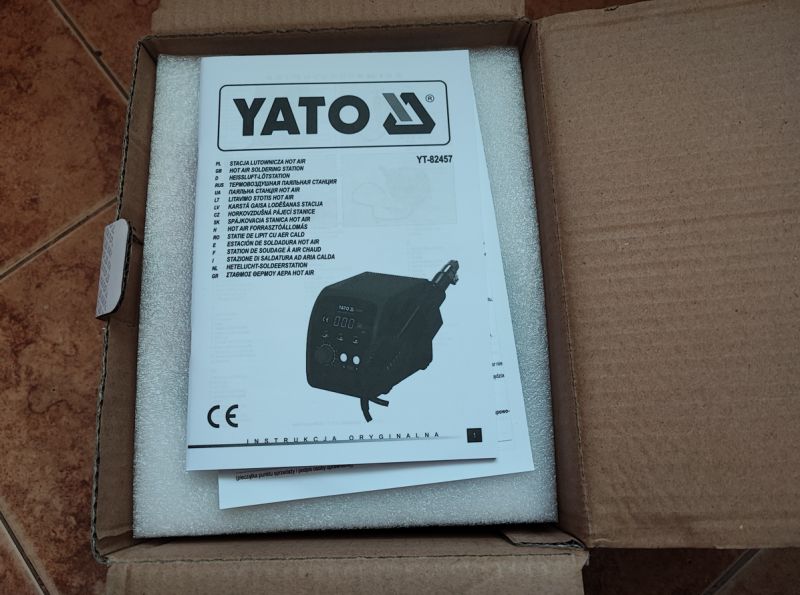

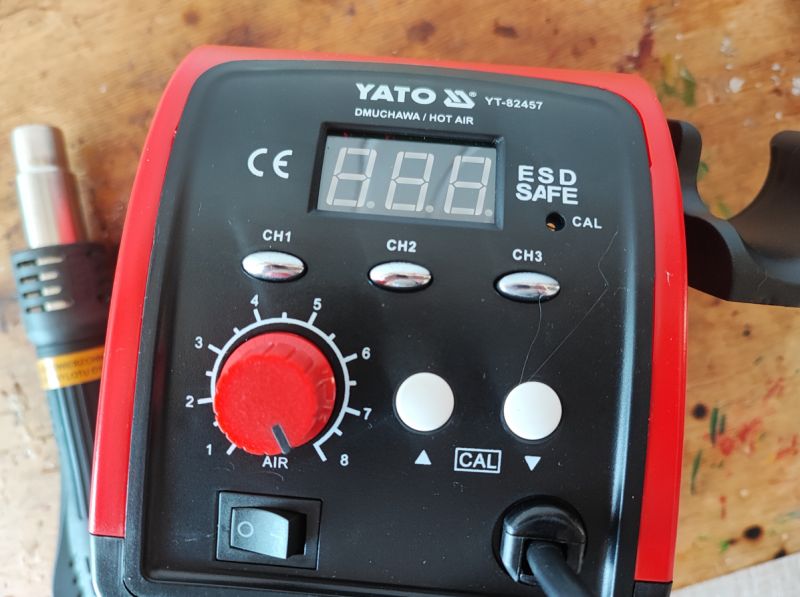

And then there is the station itself:

.

.

Here is the first remark - this station has the possibility of setting three programmes which can make our work a little easier. The 858 discussed earlier did not offer this.

.

.

The display is quite clear, while the casing seems to be quite cheap plastic.

.

.

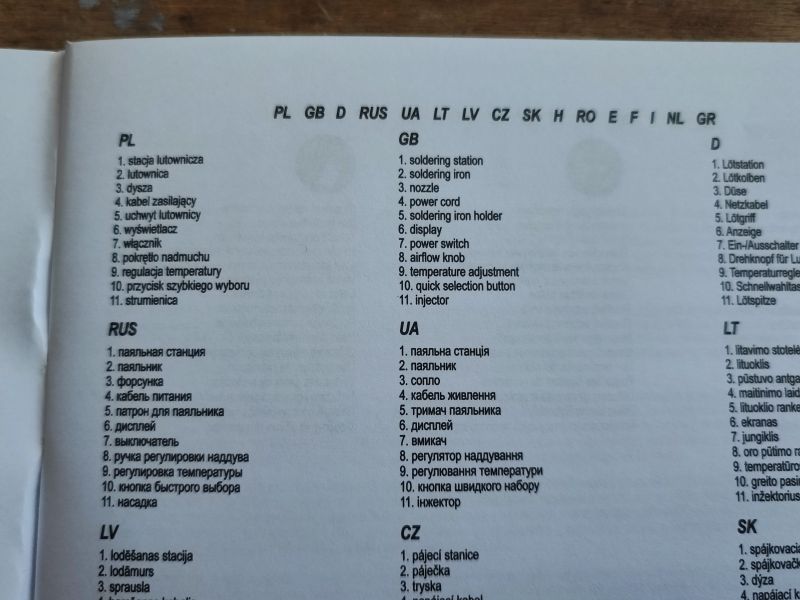

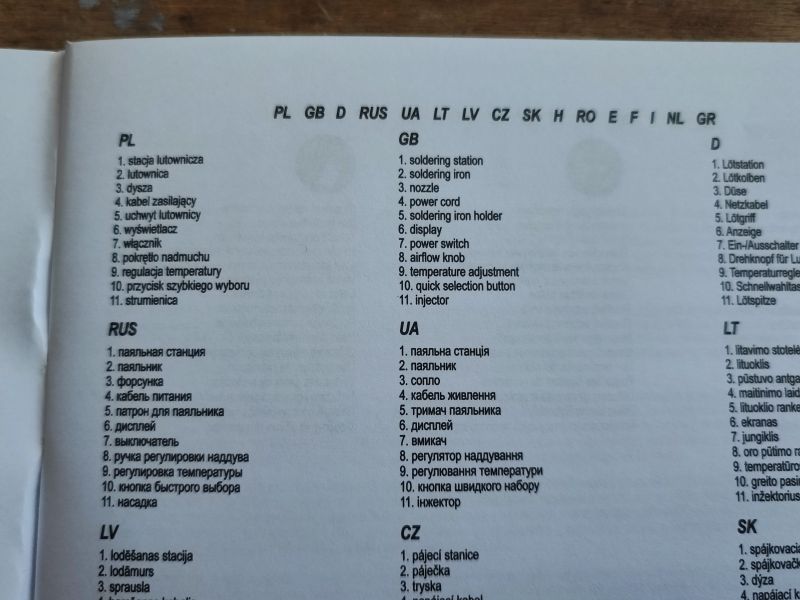

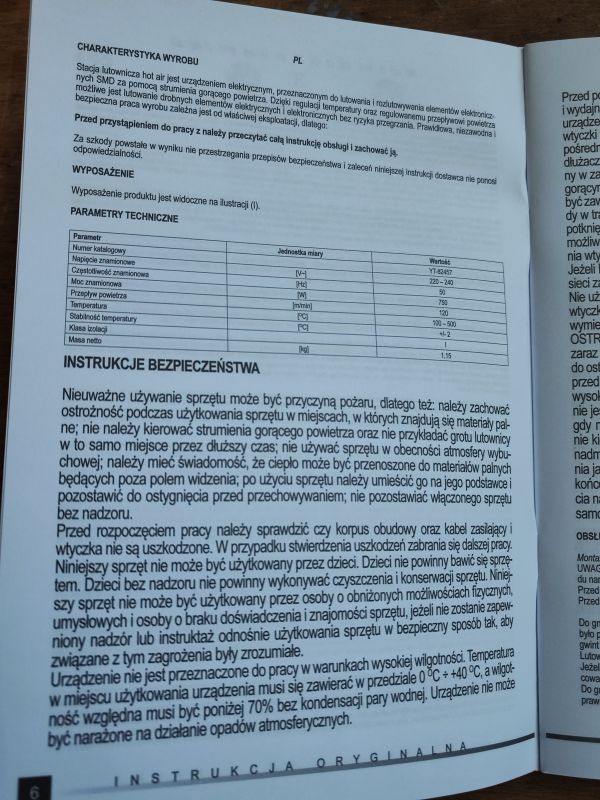

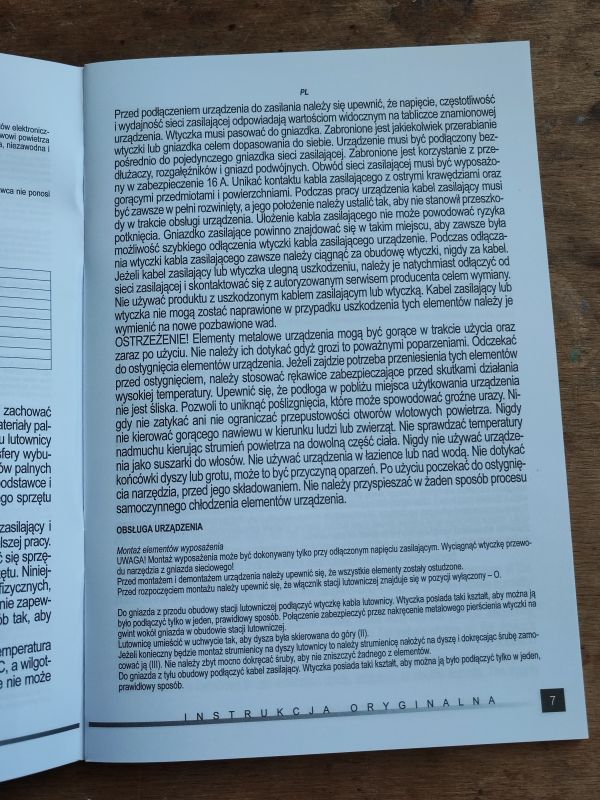

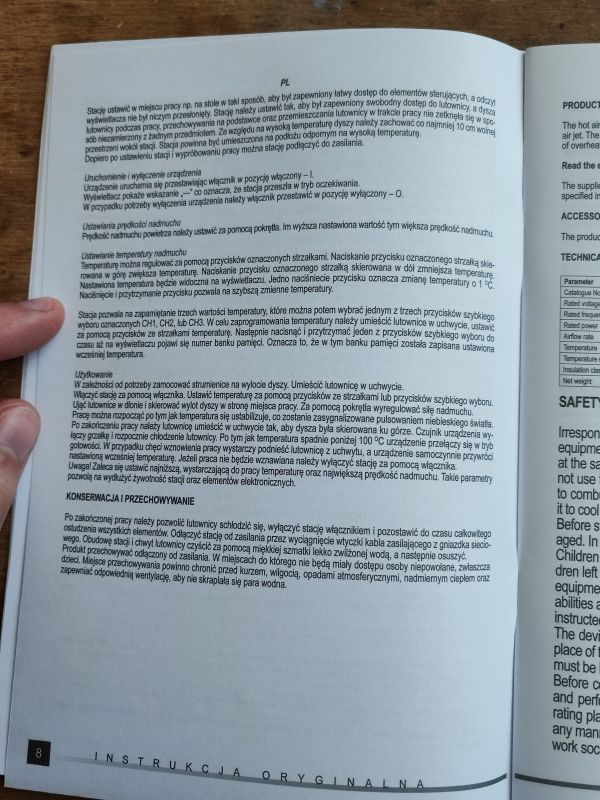

Instructions in Polish:

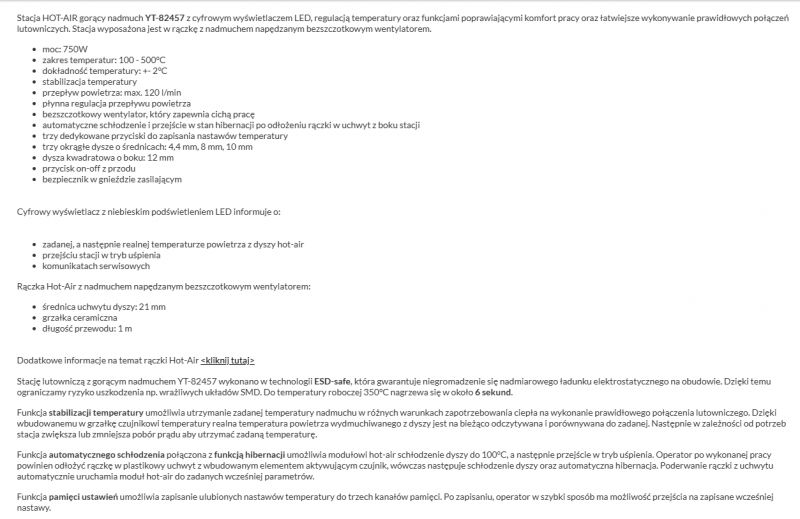

Specifications and description in Polish:

.

.

Organisational issues .

Before we move on to the tests proper, I would like to highlight a few things here:

- all tests were performed on discs made from electro-waste

- the video clips do not show the correct methods of desoldering

- therefore in the videos I do not use kapton tape to protect adjacent components

- I do not ensure that the component does not "fly away" when blown by hot air

- the boards on the videos may not be thoroughly washed of flux

- in the videos I am "impatient" and move parts that should be left alone during the casting process, because if we use force we may break the pads

- etc. etc.

The topic "how to replace the MOSFET correctly and wash the board" will be covered separately. Here I am just testing hot air.

Videotests Yato YT-82457 .

Time for some experiments. For all the videos below I have made the following assumptions:

- at the beginning of the video the station is switched off, it is completely cooled down to room temperature, the board similarly

- 8.4mm nozzle or no nozzle (you can see in the video; yes, that's my nozzle, not any of the kit)

- highest blow rate, if the specification is to be believed, 120l/m

- films are not processed

Let's start with lower temperatures. 350°C, full blow, motherboard from a laptop, chip soldering in an SO8 or similar enclosure:

90 seconds to remove, but this is without flux.

350°C, attempting to remove the coil from a large copper spout:

Unsuccessful, I gave up after 2 minutes. I then let the plate cool down. Test at 400°C:

Success in just over a minute.

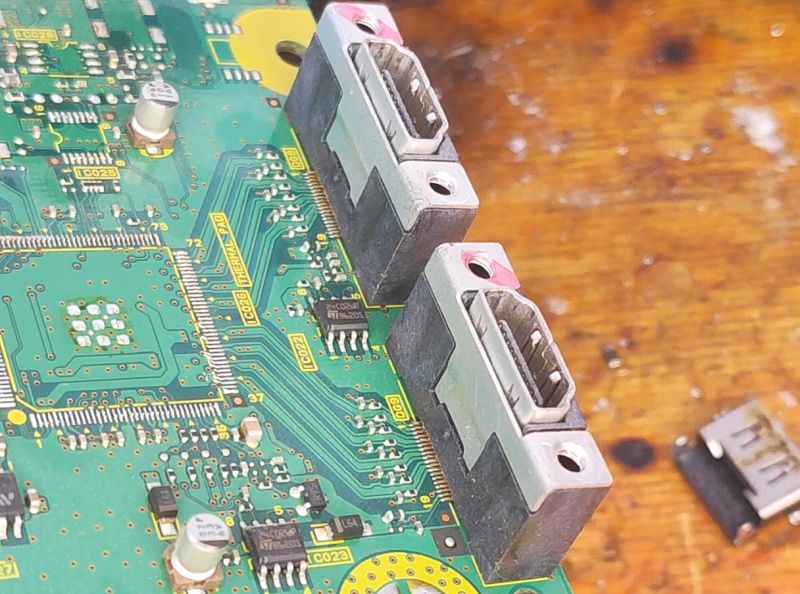

400°C, soldering of the standing HDMI socket by heating on the other side of the PCB:

.

.

It was possible to remove the socket without tearing the tracks or melting the socket itself.

450°C, MOSFET transistor soldering from a computer motherboard:

Soldered out in less than a minute.

Drawings [/size]

Such games of soldering a component out of scrap in time may be fun, but it's also better to measure something. The standard assumption here is to use the largest overblow, although in many cases it could be reduced (then it could also heat a bit harder), but that's the assumption I started with and it's hard to change anymore.

I made the graphs based on my set up with a thermocouple:

OpenBeken configuration for hot air testing - MAX6675, temperature and power logging .

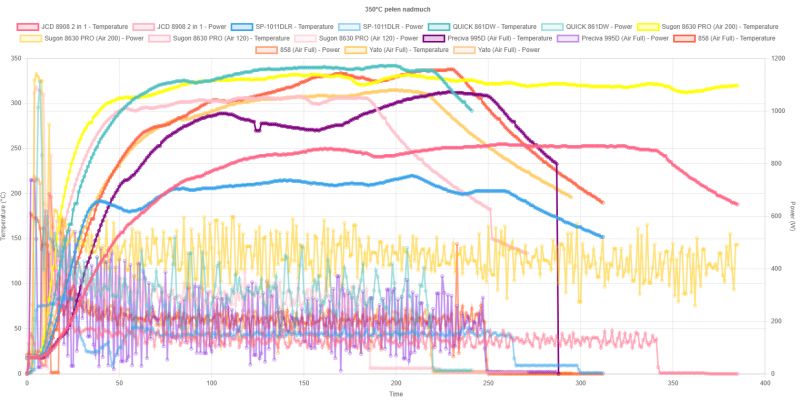

First a graph at 350°C:

.

.

After about 100 seconds, the probe actually recorded over 300°C.

Interactive version:

https://openshwprojects.github.io/hotair/version5/350c.html

Now the graph at 450°C:

.

.

After about 90 seconds, the probe actually recorded over 350°C, then the temperature already rose more slowly and approached 375°C in 200 seconds.

Interactive version of the graph:

https://openshwprojects.github.io/hotair/version5/450c.html

The final evaluation will be in the last paragraph.

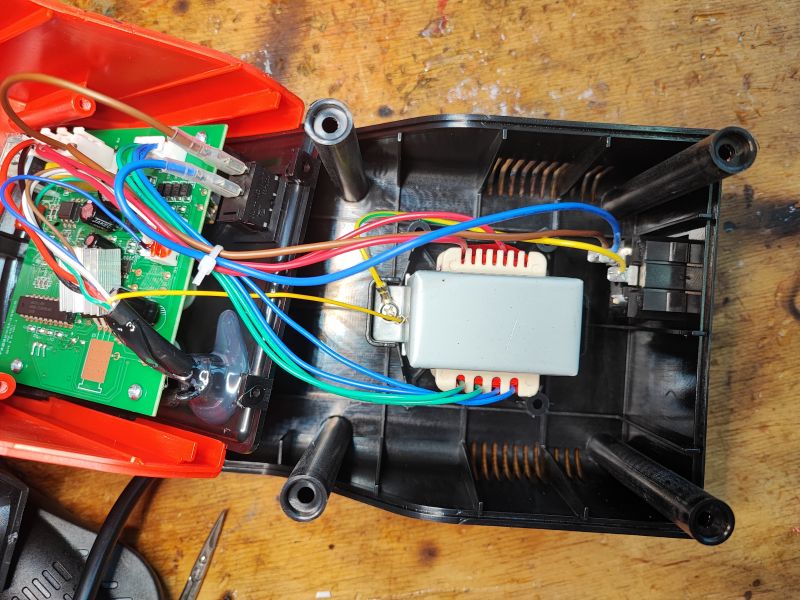

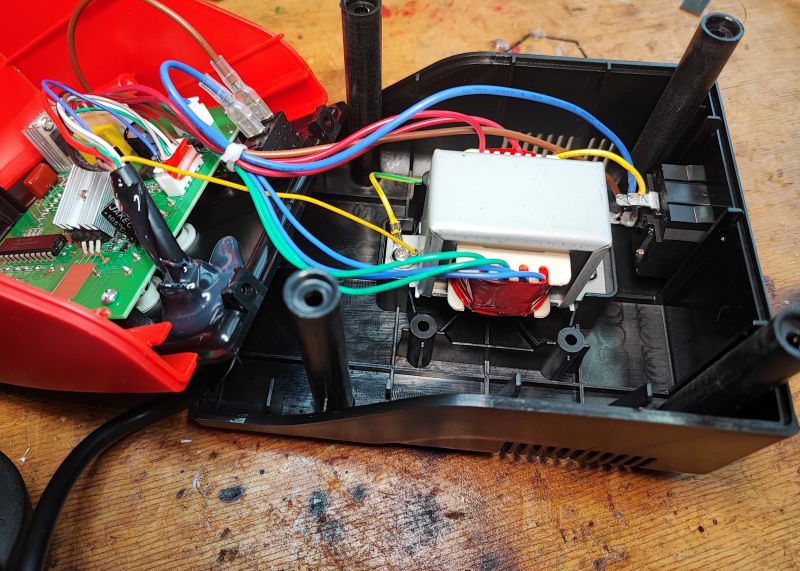

Interior .

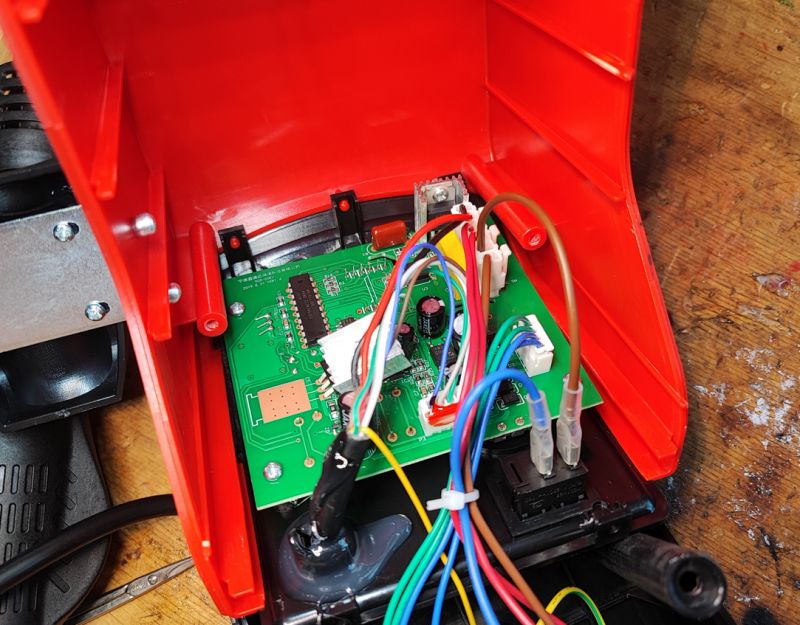

We take a look inside:

.

.

The first thing that catches the eye is the 50/60Hz mains transformer. The 858 had a boost converter.

.

.

.

.

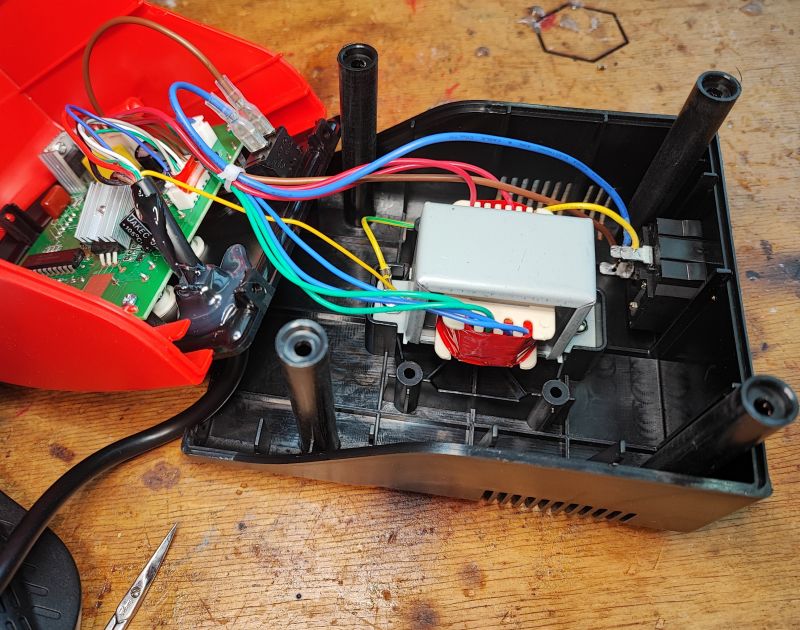

The ground is connected...

.

.

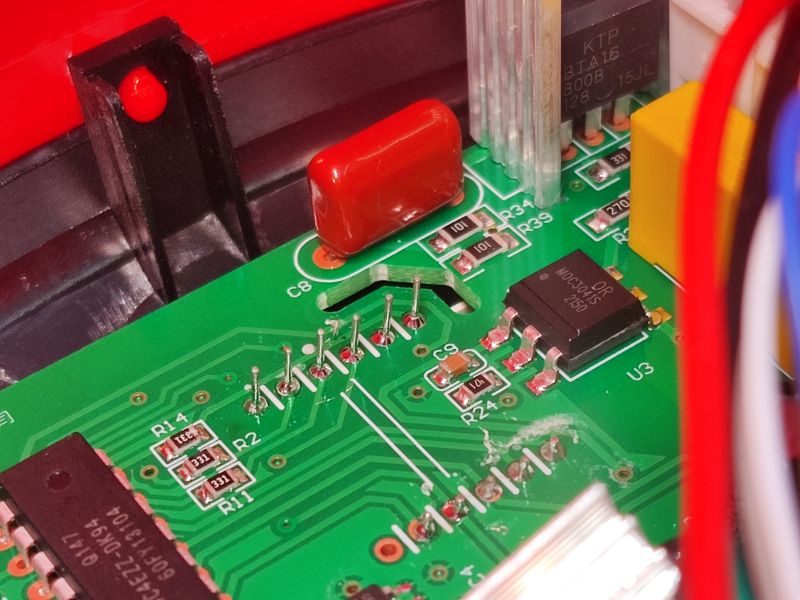

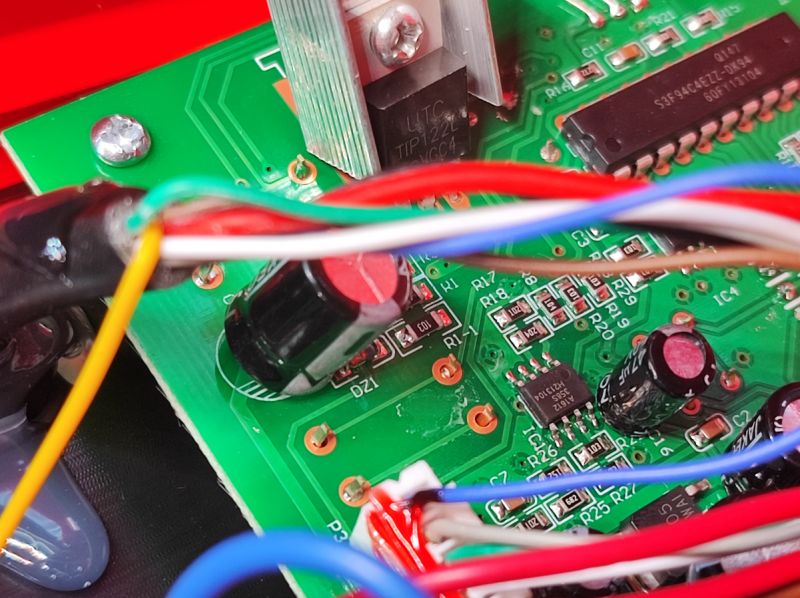

Inside, the regulation is again on a BTA16-800B triac (in the 858 there was a BTA12), controlled by a MOC3041S.

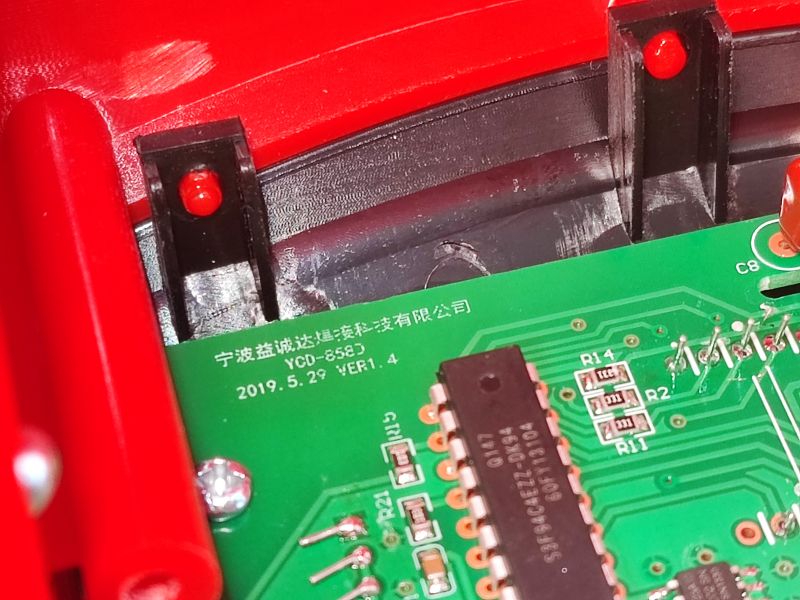

The PCB designation is. YCD-858D. Well rather unsurprisingly, this is a very popular design.

.

.

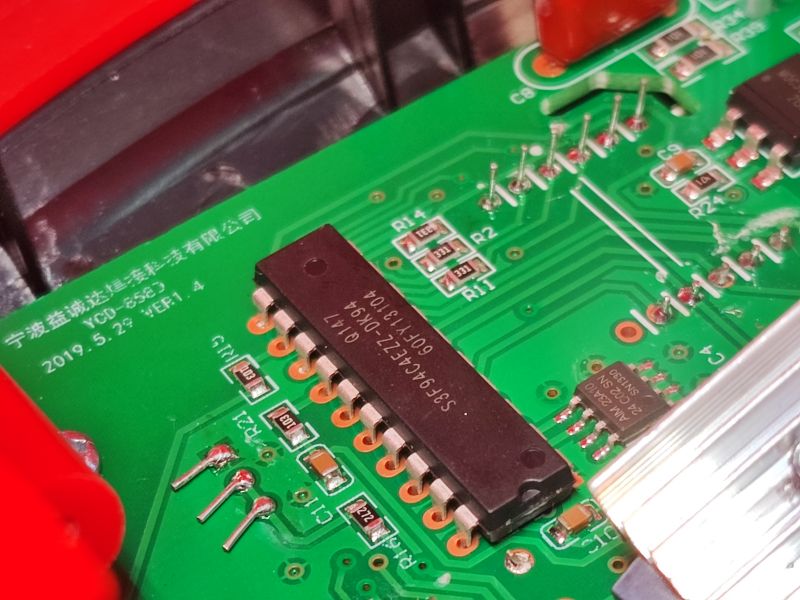

The whole design is based on the S3F94C4EZZ-DK94 MCU. The microcontroller is manufactured by Zilog. Next to it I also see an EEPROM - 24C02SN, I wonder what they hold there, calibration, settings?

.

.  .

.

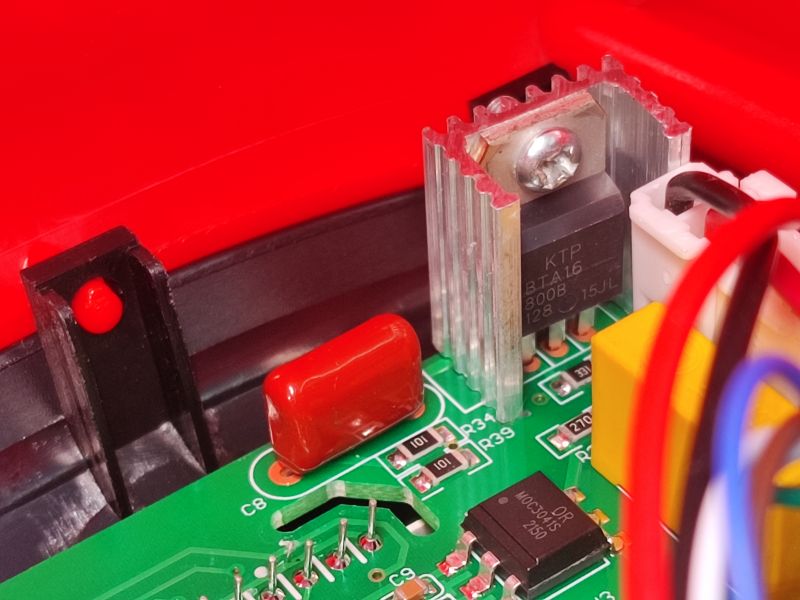

I was still interested in this transistor - it's a TIP122L, maybe from the air supply control? Interesting that it's mounted on an extra heatsink, although there's room on the PCB to solder it on. Maybe it was overheating in the previous version, hence the change?

Summary .

My first impression of this station is quite positive. I don't feel here the problem I wrote about with the JCD 8902 that the station lacks heating power at all, which meant that with the 8902 I wasn't able to remove the MOSFET transistor from the computer board without helping myself with a mainsheet or heater.

The measurements are not bad either, although here it should be borne in mind that I do not verify in my tests whether the airflow is really that 120l/min. In any case, comparing the performance of the stations I tested at the full blow setting, I see a lot of similarity between the Yato YT-82457 and the 858, the construction is also quite similar. The Preciva 995D is still slightly better than both of these stations, while all of them are further outperformed by the Sugon 8630 PRO and Quick 861DW. The JCD 8902 2 in 1 and the SP-1011DLR fall far behind.

I also tested the side functions such as the memory of three programmes (remembered when the power is switched off) and the detection of the flask being put down, I have no complaints here.

So the only question left is, what is a good buy on a budget of 35$? The previously tested Hot Air Station 858 was also good, but it did not have the possibility to set three programmes, so in terms of budget products, this one probably comes out on top. I wonder what its failure rate is after prolonged use, but I have no way of checking this "on the spot"....

And what is your opinion? Which hot air station do you use? Feel free to discuss. .

Cool? Ranking DIY Helpful post? Buy me a coffee.