.

.

Today, a 40-inch TV from my extended family comes to the table. The family first tried to have the TV serviced, but the service said it was uneconomical to repair and would cost a few hundred zloty, so we have the opportunity to experiment. The symptom of the fault is simple - the picture is very dark, especially on one side of the screen. Definitely the backlight is damaged. The equipment itself is quite old, from what I can see the 6400 series started coming out in 2013.... so some 10 years old already, but maybe there is something to fight for?

.

.

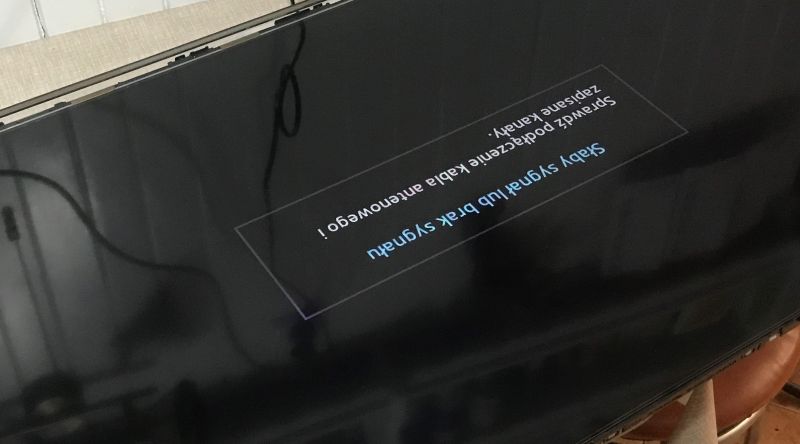

It's hard for me to show in a photo what the image looks like, but simply the brightness level is very low, although something of the backlight is still glowing:

.

.

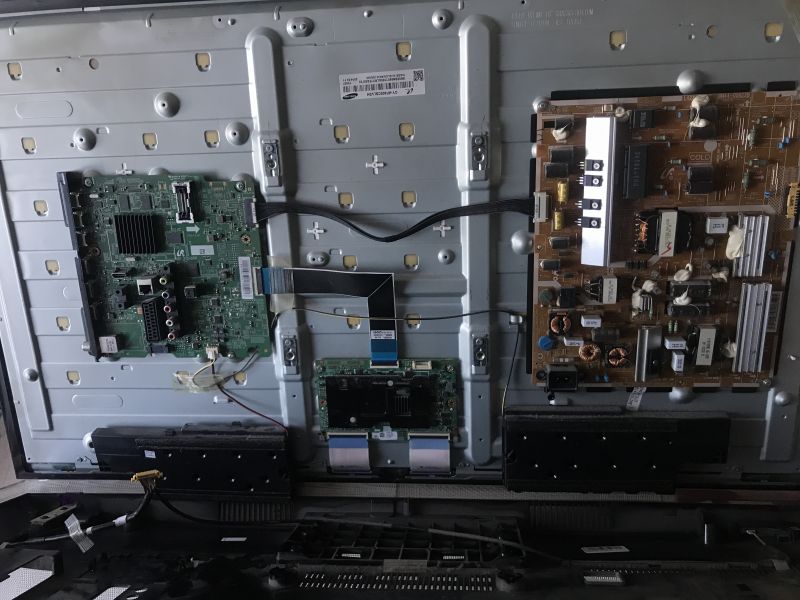

We take a look inside. First the screws.

.

.

.

.

I don't think I need to check the power supply from the LEDs, as it's almost certainly some LEDs from the backlight strips that are burnt out. It would be different if the backlighting was not there at all. Then one might wonder if it is indeed the power supply or maybe the strips.... you could then use an LED backlight tester:

Trash TV, LED tester, LED backlight repair on a zero budget .

Here, however, I assume that we don't have one , the fun has to be educational.

So you have to get under the screen. The matrix has to be removed, unfortunately. First I remove the tape and metal rails protecting the board from the matrix:

.

.

I remove the plastic bezel:

.

.

You have to be careful with the matrix, because one wrong move and the repair will be totally unprofitable.

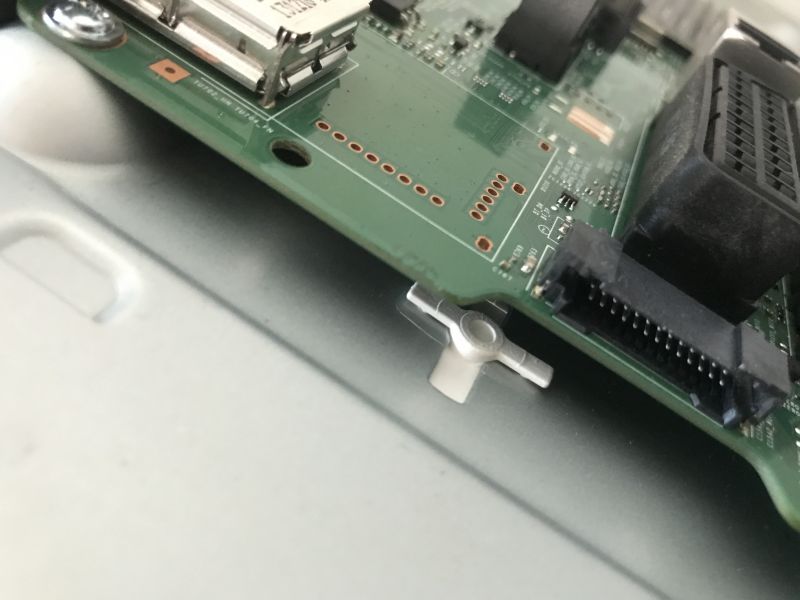

Then I removed the plastic border, it is only on the hooks. I did not take a picture of them this time. I also removed those white diffusion films. This is how I got to the backlighting. You still have to expose the LED strips, because they are covered by a white film that reflects light. It is held in place by plastic parts that you simply twist 90 degrees and pull out - it doesn't break!

.

.

.

.

This is how we get to the backlighting. The best and easiest way is to replace the whole strips, there are several good arguments for this:

- replacing whole strips is simpler (no soldering required)

- LEDs can differ in performance between strips, sometimes this can be noticeable

- even the working LEDs from the old strips may be running out, so if you do not replace the whole strips, the TV may come back to you very quickly

But there is also one argument in favour of the so-called 'carving', viz:

- COSTS - buying a new strip costs money and after all, you can flip the LEDs themselves from some old strips from another scrapped TV....

So let's try this more difficult way. We need to determine which LEDs are damaged. .

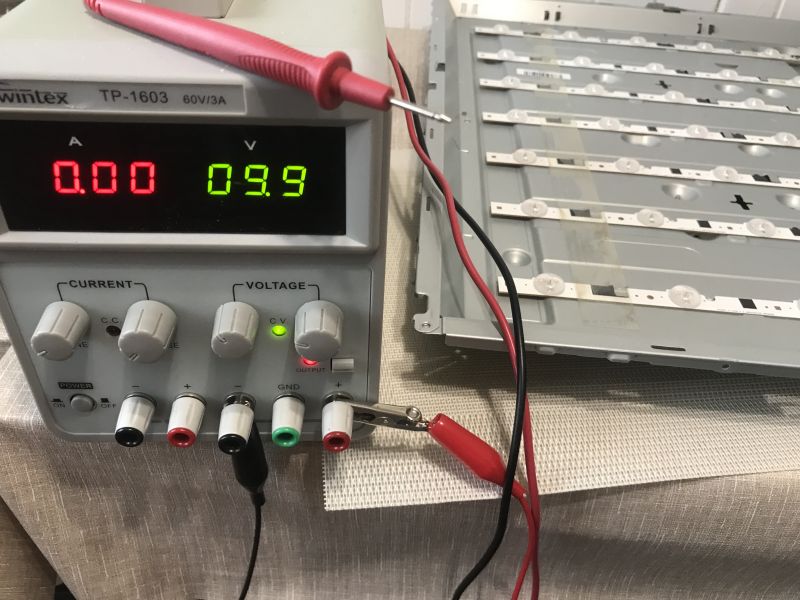

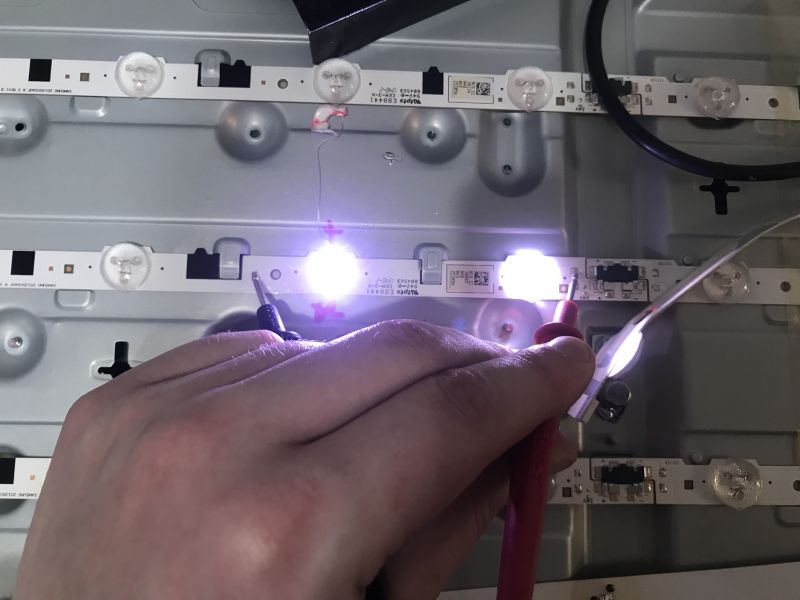

You can use a laboratory power supply in current limiting mode. This is because the diodes are current controlled. Here there is no calculated resistor to limit the current, moreover there would be losses on it.

This must be a current-limited power supply, connecting a normal power supply will not work, too much current will flow and we may damage more diodes.

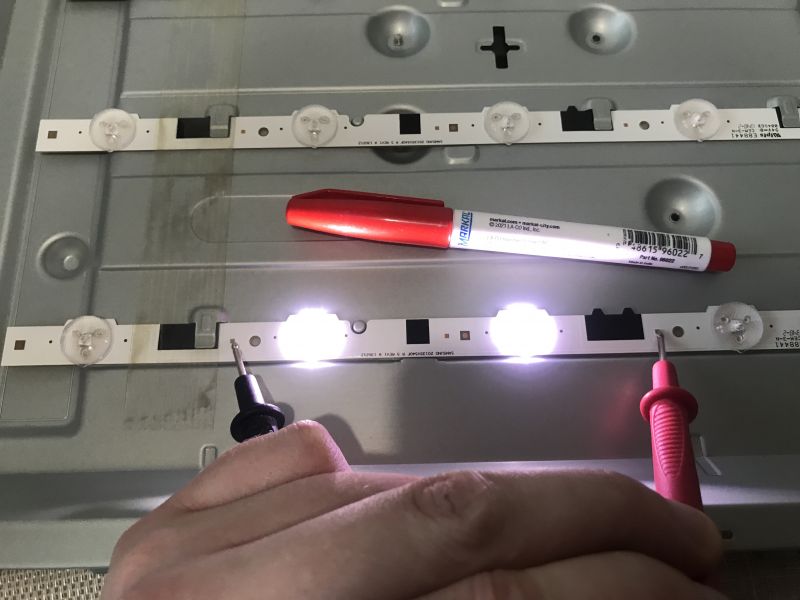

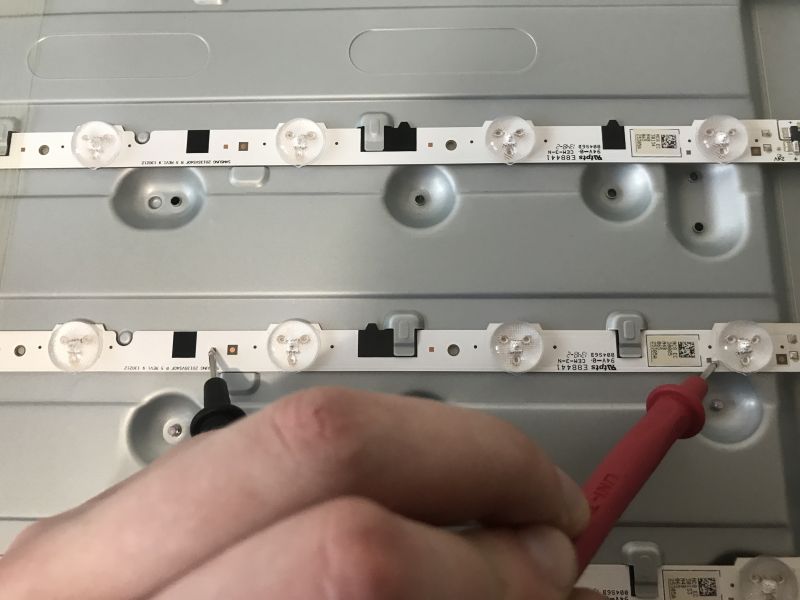

So, I set the current limit on my power supply as low as possible (only gradually increasing it as needed), connected the probes and started testing:

.

.

.

.

Indeed, most LEDs light up, but we have to work by elimination.

.

.

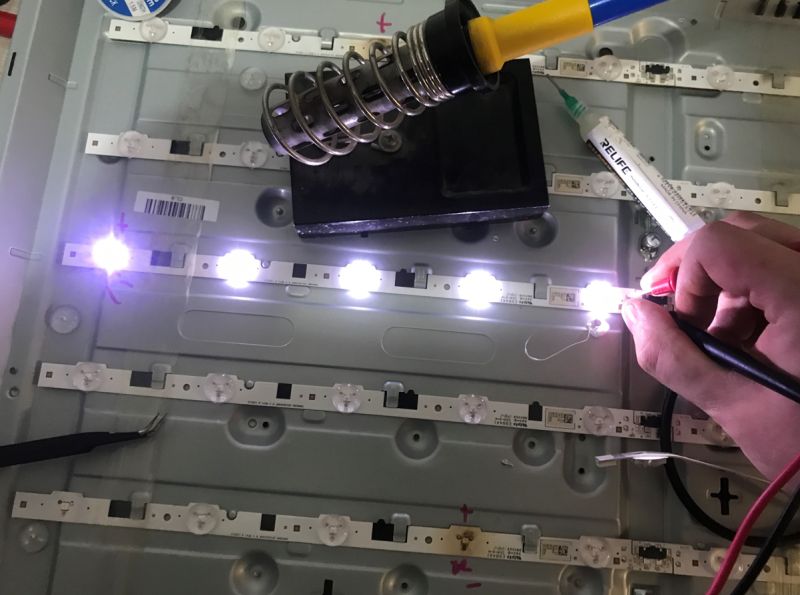

It's not that difficult, my power supply manages to light up to 5 connected in series:

.

.

.

.

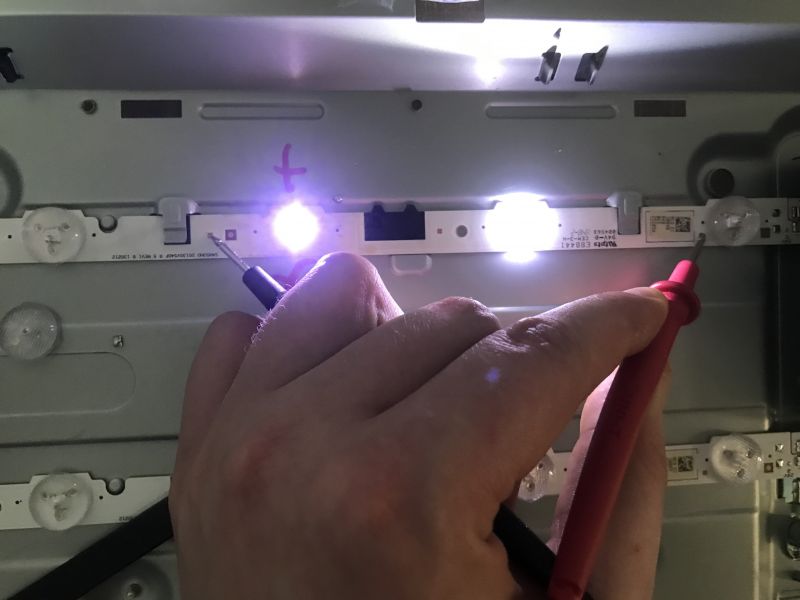

I put crosses next to damaged LEDs:

.

.

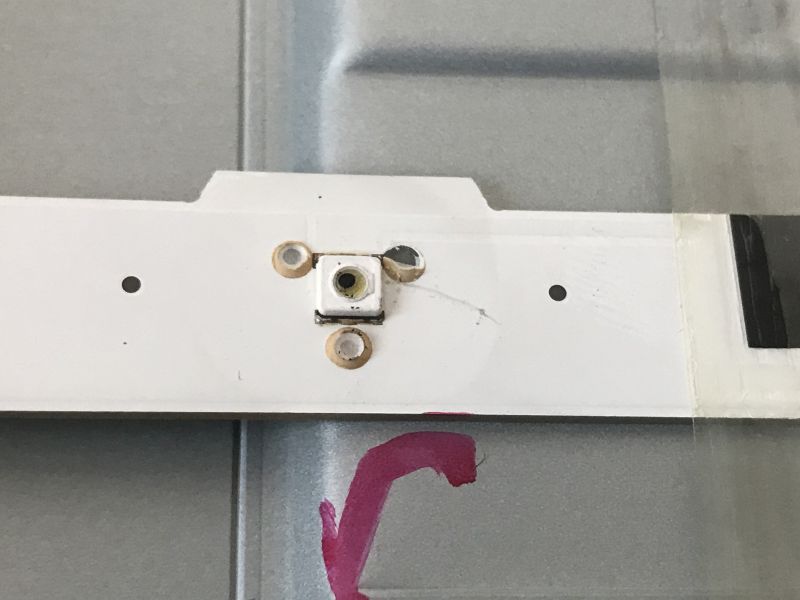

After removing the glass/diffusers you can see the damage to the LED with the naked eye:

.

.

In addition, I also marked the polarity of the diodes , because here you can't solder them the other way round - fortunately I can trace with the paths where I connected the plus and where the minus so that the others light up.

The diode now needs to be removed. The diodes hold very firmly, and if you don't remove the strips then the sheet metal also acts as a heat sink. I help myself with flux and sometimes also add lead binder to the solder. It takes a bit of effort, the hot air station has to have the heating power to be able to cope, I have tested some of these stations and not all are as good as they seem:

Quiet hot air station? ZD-8908 and maximum blowing of 20 l/min - tests and measurements .

I got the LED donors from previously scrapped equipment.

With the power supply ready, I tried to select something matching in voltage and brightness from my set of LED strips. Eventually I soldered the new LEDs, with the pads from the LEDs previously cleaned of lead-free binder with braid and applied my own, classic Cynel, as lead binder has a lower melting point and solders better.

In the photos you can see the 'new' LEDs already soldered in. I have to admit that I blew one of them out on occasion, so it is better not to count "on contact" how many we need.

.

.

.

.

.

.

You can see the difference to a small extent, but that's because I didn't stick the slides for the photos. Of course, they too must be back in place, otherwise you will see the dots on the TV!

The essential operation is now complete.

TV in the process of being assembled:

.

.

Assembled:

.

.

.

.

It seems that everything is working.

The TV has already been returned to the owner and, according to her, "there are no visible repairs to the picture".

Now still need to summarise.

Would I give such a compilation to a customer? Of course not. It's impossible to give a warranty on something like this, because if these 3-4 LEDs have died, more may soon die too. I don't think anyone wants a visit from a dissatisfied customer who says that it worked for a week and then died....

It's a different situation when you need to help an elderly family member - then the TV is in my sights and you can play around, and undoubtedly zero repair cost (only 30 minutes of fiddling) is a great asset to the whole thing.

I already have some LED strips (parts donors) set aside from "wrecks", and sometimes manage to resell some on the internet (sometimes also with electronics from the "wreck").

We'll see how much it lasts from today and when the TV comes back to me.

If it wasn't an LED backlit TV I don't think I would have played around at all but scrapped it straight away because then the power consumption would be higher, but I think with LEDs there is something to fight for.

The only thing I did more on the spot was to reduce its brightness slightly....

PS: Of course the method shown will also work if you are investigating which strip has died and want to replace the whole strips, you don't have to do as I have shown. Maybe it will be useful for someone.

Cool? Ranking DIY Helpful post? Buy me a coffee.