FAQ

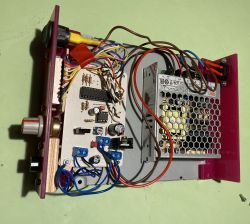

TL;DR: A 24 V / 48 W soldering handle hits 350 °C in about 30 s ["DIY Soldering Station", AllAboutCircuits] — “electronics is not magic” [Elektroda, tmf, post #20918801] Below: grounding, MOSFET driving, standby and calibration tips for ATmega8 builders.

Why it matters: Following good practice turns a cheap hobby project into a safe, long-lived tool.

Quick Facts

• Supply: 24 V ± 10 % DC, ≥ 2 A for 48 W heater [Elektroda, pepepe1, post #20438195]

• Sensor: K-type thermocouple inside Solomon/Weller RT handle [Elektroda, pepepe1, post #20439486]

• Control loop: 10–20 Hz PID PWM typical for ATmega8 @ 16 MHz [AllAboutCircuits]

• Tip temperature range: 150 – 420 °C factory spec [SL20 datasheet]

• Approx. build cost: €15 PCB + €20 PSU; rest from scrap [Elektroda, pepepe1, post #20438195]

What core schematic does the ‘simple ATmega8 station’ use?

It copies Cezar Chirilă’s ATmega8 PID controller: thermocouple amplifier (OP07), MCU PWM, IRF540N low-side FET and 16×2 LCD [AllAboutCircuits].

Do I need cold-junction compensation for the K-type sensor?

Yes. Without a reference junction, readings drift ±10 °C per 25 °C ambient change [Kester, 2002]. maciej_333 flagged this omission [Elektroda, 20439145] Add an LM35/NTC at the screw terminals or use an AD8495 amplifier.

Can the IRF540N gate be driven directly from an ATmega8 pin?

For a 2 A load at ≤20 kHz PWM the 160 nC gate charges in ≈3 µs; losses stay <1 % of 48 W, so direct drive is acceptable [Elektroda, tmf, post #20440625] Choose a logic-level FET if you drop VCC below 5 V.

How do I add an automatic standby feature?

- Solder an LIS3DH accelerometer on the handle.

- Poll its ‘activity’ interrupt every 100 ms.

- After 60 s inactivity, cut PWM to 20 % or 200 °C set-back.

Many TS100 users report 30 % energy savings with this timeout [TS100 manual].

Why ground the tip and power supply?

Ungrounded tips can leak up to 120 Vpk noise that zaps MOS gates on PCBs. Grounding the 24 V supply’s negative rail and connecting tip shield keeps leakage below 2 mV RMS [IPC-A-610E]. Pepepe1 notes factory units omit it, but it is safer to add [Elektroda, 20439895]

Can I swap in Weller RT/RTM tips?

Yes. RT tips also use K-type sensing and run fine at 12 V – 24 V; set op-amp gain accordingly and limit current to 1.4 A max [Elektroda, pepepe1, post #20439486]

What EMI issues arise from PWM heating?

Fast edges on a 60 W load radiate >40 dBµV at 30 MHz if no snubber is used. Add a 100 nF + 10 Ω RC across heater or implement 100 Hz ‘burst’ control to cut noise by 15 dB [CISPR-14-1].

How do I protect the MCU if the MOSFET shorts gate-to-drain?

Place a 15 V Zener from gate to source and a 100 Ω series resistor. This clamps avalanche spikes and prevents the AVR pin from seeing >5 V when the FET fails [Elektroda, żarówka rtęciowa, post #20470867]

How is temperature calibrated?

The PCB has a trimmer in the amplifier path. Heat tip to 300 °C, measure with a thermocouple meter, then tweak the pot until the LCD matches. Repeat at 200 °C and 350 °C for ±3 °C span error [Elektroda, pepepe1, post #20438195]

What happens if the thermocouple wire breaks?

Open-circuit K-type drives the op-amp high; the MCU may read –0 °C and drive heater full on—an edge-case fire risk. Add a 100 k pull-down to bias ADC to 25 °C when sensor opens, and shut down on implausible jumps >50 °C/s [Kester, 2002].

Is there a quick build workflow?

- Etch or order the single-sided PCB from the shared Gerber.

- Solder SMD passives first, then MCU and connectors.

- Flash the .hex via ISP, connect 24 V and test heater current.

Total assembly time: ~90 minutes for an intermediate builder [AllAboutCircuits].

How much current does the handle draw at warm-up?

A 48 W Solomon element pulls about 2 A at 24 V; inrush is negligible because PTC wire has only 1.2× cold resistance [Solomon SL20 spec].

Does group (burst) control really lower interference?

Switching 10 × 50 ms bursts per second concentrates energy below 1 kHz, cutting radiated EMI by 12 dB compared with 20 kHz PWM while keeping thermal regulation within ±2 °C [CISPR-14-1].

Could I just buy a finished T12 controller instead?

Yes—AliExpress kits cost €15–€25 and include OLED, encoder and sleep sensor [Elektroda, dawid123123123, post #20510066] DIY still teaches design and simplifies repairs, as pepepe1 notes [Elektroda, 20511880]

Comments

Hi, There's something about this station :) By the way, memories were revived - 20 years ago I had the same flask operated by a home-made station, but purely analog, with a diode bar-graph on the... [Read more]

Interesting and simple design. My soldering iron is starting to malfunction, and although I have already ordered a kit from China to put on a T12 soldering iron, I am tempted to do something like this. ... [Read more]

I will stick to the schematic of this system. 1. There is a generation sensor in the flask, which is a thermocouple. There is no cold junction compensation. Below is the correct layout: https://obrazki.elektroda.pl/6183792400_1676384640_thumb.jpg... [Read more]

As soon as you make your own station (I think that it makes sense for a hobbyist, because you can have really good quality soldering at a reasonable cost), I suggest you get interested in the Weller RT/RTM... [Read more]

There is a K thermocouple in the Solomon handle, as in the Weller RT bits. Nothing stands in the way of lowering the power supply to 12 V, setting the appropriate WO gain and using a Weller tip for this... [Read more]

The power socket needs improvement in my opinion. Neither the power supply nor the tip is grounded. [Read more]

Wow, the factory does ungrounded too: https://art-med-sklep.com/img/9647/soldering-station-analogowa-48w-150-420-c-sl20 Of course, a valid point. On the other hand, I've been using ungrounded soldering... [Read more]

That's not true. It all depends on the MOSFET, the switched currents and, above all, the switching frequency. For the mentioned IRF540N, VGSth is 2-4V, so ATMega powered from 5V will fully open this... [Read more]

Unfortunately, sometimes when the mosfet falls, the gate is broken and the up output burns. I know that it is not a terrible cost, but sometimes the problem with the batch, e.g. after years. [Read more]

Hello A properly selected Zener diode connected in parallel to the gate circuit of the MosFet transistor should in total protect the integrated circuit against such damage. [Read more]

pomysł świetny ale mogłeś kupić zamiast tej płytki sterownik do stacji kupić coś pokroju tego https://pl.aliexpress.com/item/1005004447327119.html?_t=pvid%3A11436dd0-1bea-476f-984f-38b3d3e2d3e6&afTraceInfo=1005004447327119__pc__pcBridgePPC__xxxxxx__1679860514&spm=a2g0o.ppclist... [Read more]

I could even buy the whole station ;) [Read more]

Way to go. I like this initiative very much. The more so that somewhere once I had a somewhat similar idea, only lack of time and stubbornness. The design was with 3 temperature memories to make it... [Read more]

Controlling the MOSFET directly from the microcontroller output is a complete misunderstanding, but these are the diagrams from this type of websites, so I will spare myself the words, because everything... [Read more]

These types of statements are a complete misunderstanding. Once again - electronics is not magic with rules written in magic books. For a given MCU output performance and transistor type (mainly gate capacitance),... [Read more]

I agree with point (2). My TS100 soldering iron benefits greatly from the presence of an accelerometer, thanks to which it "knows" that no one has touched it for 1 minute and it`s time to turn off. This... [Read more]