However, I was wrong. This second set of parameters is not for communication with the valve but with the Spider module.

The modules work in Modbus RTU, with a speed of 9600.

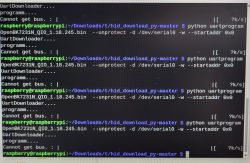

The communication looks like this:

1. Cobra sends a register request from address 0:

005 004 000 000 000 001 048 078

Spider responds with code 054 147:

005 004 002 054 147 031 061

(2) Cobra queries modem version and status (addresses 1-9):

005 004 000 001 000 008 161 136

Spider replies:

005 004 016 000 212 000 000 000 000 000 000 000 000 000 002 000 015 000 000 057 128

where:

005-module address

004 - Modbus message type

016 - number of returned bytes

000 212 - version 2.12

000 000 CH setting change

000 000 Change of HUW setting

000 000 1=start

000 000 1=stop

000 002 - modem status (001 - initialisation, 002-SIM error, 003-PIN error, 004-logging in, 005-logged in, 006-SMS error)

000 015 - GSM signal level

000 000 - ?

057 128 - CRC

The return of this message with a changed CH, DHW or start/stop setting temperature changes the Cobra settings.

Cobra saves the parameters to the module

005 016 000 000 040 080 000 000 002 172 002 158 000 255 001 003 000 002 000 039 000 080 000 000 001 043 052 056 XXX XXX XXX XXX XXX XXX 000 000 000 043

where:

005-address of module

016 - Modbus message type

000 000 - address of first register

040 080 - 40 registers, 80 bytes

000 000 - error codes (description at the bottom)

002 172 - CH temperature

002 158 - HUW temperature

000 255 - feeder temperature

001 003 - return temperature

000 002 - room thermostat status (0 - off, 1 - on, 2 - not working)

000 039 - set CO temperature

000 080 - set temperature of DHW

000 000 - whether controller is turned on (000 001 - on)

000 001 - whether the controller is off (works alternately with the previous register - only one of them is set to "1")

043 052 056 XXX XXX XXX XXX XXX XXX XXX XXX 000 - first phone number stored in ASCII

000 000 000 043 052 000 000 - ??

043 052 056 049 049 049 049 049 049 048 000 - second telephone number recorded in ASCII (here +481111111110)

000 000 043 052 000 000 - ??

043 052 056 057 057 057 057 057 057 057 057 057 000 - third telephone number recorded in ASCII (here +489999999999)

000 000 - ??

068 - oven temperature in degrees (no fractional part)

000 000 000 - ??

112 134 - CRC

Error codes are in the form of flags. In the first byte, 5 lower bits can be set, in the second byte all 8. Setting several bits will send all set alarms in the text.

first byte:

bit 1 (1) - Large feeder current

bit 2 (2) - High DHW pump current

bit 3 (4) - CH pump high current

bit 4 (8) - Igniter high current

bit 5 (16) - Blower high current

second byte

bit 1 (1) - High boiler temperature

bit 2 (2) - Bin fire

bit 3 (4) - STB alarm

bit 4 (8) - Feeder blockade

bit 5 (16) - Fuel shortage

bit 6 (32) - Open hopper

bit 7 (64) - Bottom ash

bit 8 (128) - Temperature sensor fault

Spider confirms data storage:

005 016 000 000 000 040 193 147

4th Cobra queries 40 registers (first address 0):

005 003 000 000 000 040 068 172

Spider responds:

005 003 080 000 000 002 166 002 157 000 244 001 132 000 002 000 039 000 080 000 000 001 043 052 056 XXX XXX XXX

where:

005 - module address

003 - modbus message type

080 - number of returned bytes

000 000 - ??

002 166 - CH temperature

002 157 - HUW temperature

000 244 - feeder temperature

001 132 - return temperature

000 002 - room thermostat status

000 039 - preset CH temperature

000 080 - set HUW temperature

000 000 - whether controller is turned on (000 001 - on)

000 001 - whether the controller is off (alternates with the previous register - only one of them is set to "1")

043 052 056 XXX XXX XXX XXX XXX XXX XXX XXX 000 - first call

000 000 000 043 052 000 000 - ??

043 052 056 049 049 049 049 049 049 049 048 000 - second telephone

000 000 043 052 000 000 - ???

043 052 056 057 057 057 057 057 057 057 057 057 057 000 - third phone

000 - ???

000 067 - CO temperature in full degrees

000 000 000 - ??

242 018 - CRC

If there is no communication for more than one minute, the module sends last error messages and a "no communication with the controller" alarm

This is probably all that can be extracted from this device

.

When communicating with Cobra, response times are very important. A delay of 100ms can result in the message being sent being rejected. After sending, you also need to add some time before switching to receive. When communicating with the Arduino, I set a 10ms delay before transmitting and 100ms at the end before switching the module to receive.