Hello all!

I would like to present a project aimed at practical implementation of the strobe lamp arrangement. Such a lamp is necessary for setting the ignition offset angle in internal combustion engines. I made the device a few years ago and so far it has served me flawlessly.

Principle of operation:

The occurrence of the stroboscopic effect can be observed when a given object moves (spins) with the same frequency (or its multiple) as the flashing light that illuminates it. Thanks to the inertia of the human eye, you can see the "stillness" of the rotating element.

This phenomenon is used in many areas, such as automotive, where it is used to precisely adjust the ignition of an internal combustion engine.

Description of the individual blocks of the device:

The light source of the device is a LED type Power LED with a power of one watt, emitting light with an intensity of 38lm. It is placed on a small heat sink because it operates at high currents (up to 300mA) and emits heat. The diode can be triggered by an impulse coming from a spark plug, or by an integrated generator. The block diagram below shows the connection of all device modules. The LED flashing frequency is continuously counted with a frequency counter. To count the frequency at a voltage higher than the target 5V, a simple voltage stabilizer system was used, which reduces the pulse amplitude to 4.7V. The diode is keyed by the BD139 transistor operating in the OE circuit. In order not to exceed its rated current, the system is equipped with a stabilizer with a voltage of about 3.3V, at which the diode consumes a current of about 250mA. As a result of the LED temperature increase during operation, its internal resistance decreases, which increases the current consumed, but the heat sink surface and the LED supply voltage are selected so that the maximum current of 300mA is not exceeded during continuous operation.

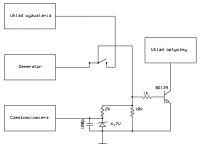

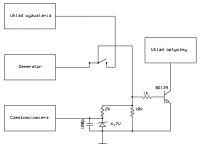

Block diagram:

Generator:

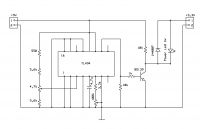

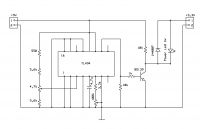

The device uses a generator based on the TL494 chip. The structure includes an oscillator, the operating frequency of which depends on the value of RC elements on pins 5 and 6, and a comparator with emitter followers at the output. It is expanded with many other elements that give additional possibilities, but the designed device does not use any other than the previously mentioned. The principle of operation is typical. At the oscillator output, a sawtooth waveform is directed to the comparator input. The second input of the comparator is influenced by the control voltage (pin no.3). Depending on the value of the control voltage, there is a different actuation threshold of the comparator, the final effect of which is a square-wave output signal with an adjustable duty cycle (PWM). The drive voltage thus determines the pulse length in each period of the square wave output. With the help of resistors it is divided in such a way that the potentiometer changes the filling in the range from 5% to 95%. The frequency of the system can be changed smoothly in the range of 4-100Hz. The structure of the circuit includes a transistor at the comparator output, working as an emitter follower, which controls the BD139 executive transistor. A 1k resistor based on it causes the base current limitation, and 10k polarized one to ground, the other to the power supply plus, discharge parasitic capacitances, so that the waveforms based on the key and output are not distorted. The executive transistor works in a common emitter system. The 1N4007 diode at its output, connected in reverse, and in parallel to the operating LED, has negative pulses generated during the time when the transistor is not conducting.

Schematic diagram of the generator:

Frequency meter:

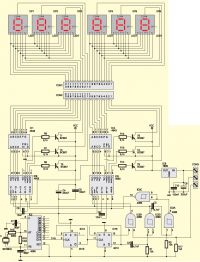

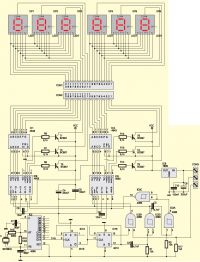

The frequency meter circuit is based on the AVT-2269 kit with minor modifications. However, half of the system is used, because in the designed device measuring the frequency up to 1kHz it is fully sufficient (3 seven-segment displays). The task of the meter is to count the pulses in a given time unit and display them on the display. The meter is clocked with a quartz-stabilized generator with a frequency of 32.768kHz. This frequency is divided by 214, which gives 2 Hz at its output, and then on the two D-type monostable flip-flops by 4, which gives a waveform with a frequency of 0.5 Hz, in which the low and high states last one second. During the high state, the logic gate is open and the second input is influenced by the measured signal. It is then counted by the counter, snapped with a LATCH latch and displayed on the seven-segment displays that are multiplex-controlled. The entire cycle is repeated every second. The arrangement in practice did not cause any major problems, but it is extremely capricious. It needs a very stable power supply (a small variable component caused incorrect operation), and a supply voltage of 5V, although the integrated circuits used can work up to 15-18V. At a voltage higher than 5V, even by half a volt, the system freezes, stopping the previously indicated value and stays in the latch. The measured signal must also have a strictly defined voltage amplitude (4.2V-5V), therefore, in order to extend the possibilities of measuring signals to 15V, the measured voltage stabilization (peak cut) was applied to the value of 4.7V on the Zener diode. The maximum relative error of the frequency measurement of the system is 0.1% + 1 significant digit. In order to calculate the error, the system was compared with the TCX0-5 reference made according to L-18 / WT-6860-074.

Schematic diagram of the frequency meter:

Power system:

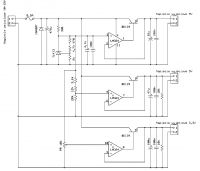

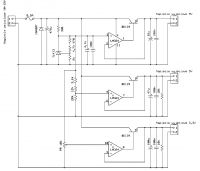

The power supply provides 9V for the generator, 5V for the frequency meter circuit, and 3.3V for the LED operating diode. The output voltages are very stable. The TL413 chip was used to obtain the reference voltage. Its value is set to 9V and then divided to 5V and 3.3V by voltage dividers. Voltage from 10.5V to 15V can be applied to the input of the power supply for the unchanging parameters of the entire system. The range covers the voltages that may occur in the automotive installation. The reference voltage, after filtering on the capacitors, goes to the positive inputs of the LM324 operational amplifiers. These amplifiers control the output transistors directly, and their negative inputs have output voltages. The operational amplifier always tends to the "virtual zero" between the positive and negative inputs, so all changes in the output voltages are compensated by them, so that the output is always, regardless of the load and temperature, the set voltage with a high accuracy. The additional capacitances filter out the voltage and allow time for the feedback (which is itself very fast) to respond to current pulses. Such pulses are taken by an executive LED diode, so its voltage must be rigid so that there is no fading effect during operation.

Schematic diagram of the power supply:

I would like to present a project aimed at practical implementation of the strobe lamp arrangement. Such a lamp is necessary for setting the ignition offset angle in internal combustion engines. I made the device a few years ago and so far it has served me flawlessly.

Principle of operation:

The occurrence of the stroboscopic effect can be observed when a given object moves (spins) with the same frequency (or its multiple) as the flashing light that illuminates it. Thanks to the inertia of the human eye, you can see the "stillness" of the rotating element.

This phenomenon is used in many areas, such as automotive, where it is used to precisely adjust the ignition of an internal combustion engine.

Description of the individual blocks of the device:

The light source of the device is a LED type Power LED with a power of one watt, emitting light with an intensity of 38lm. It is placed on a small heat sink because it operates at high currents (up to 300mA) and emits heat. The diode can be triggered by an impulse coming from a spark plug, or by an integrated generator. The block diagram below shows the connection of all device modules. The LED flashing frequency is continuously counted with a frequency counter. To count the frequency at a voltage higher than the target 5V, a simple voltage stabilizer system was used, which reduces the pulse amplitude to 4.7V. The diode is keyed by the BD139 transistor operating in the OE circuit. In order not to exceed its rated current, the system is equipped with a stabilizer with a voltage of about 3.3V, at which the diode consumes a current of about 250mA. As a result of the LED temperature increase during operation, its internal resistance decreases, which increases the current consumed, but the heat sink surface and the LED supply voltage are selected so that the maximum current of 300mA is not exceeded during continuous operation.

Block diagram:

Generator:

The device uses a generator based on the TL494 chip. The structure includes an oscillator, the operating frequency of which depends on the value of RC elements on pins 5 and 6, and a comparator with emitter followers at the output. It is expanded with many other elements that give additional possibilities, but the designed device does not use any other than the previously mentioned. The principle of operation is typical. At the oscillator output, a sawtooth waveform is directed to the comparator input. The second input of the comparator is influenced by the control voltage (pin no.3). Depending on the value of the control voltage, there is a different actuation threshold of the comparator, the final effect of which is a square-wave output signal with an adjustable duty cycle (PWM). The drive voltage thus determines the pulse length in each period of the square wave output. With the help of resistors it is divided in such a way that the potentiometer changes the filling in the range from 5% to 95%. The frequency of the system can be changed smoothly in the range of 4-100Hz. The structure of the circuit includes a transistor at the comparator output, working as an emitter follower, which controls the BD139 executive transistor. A 1k resistor based on it causes the base current limitation, and 10k polarized one to ground, the other to the power supply plus, discharge parasitic capacitances, so that the waveforms based on the key and output are not distorted. The executive transistor works in a common emitter system. The 1N4007 diode at its output, connected in reverse, and in parallel to the operating LED, has negative pulses generated during the time when the transistor is not conducting.

Schematic diagram of the generator:

Frequency meter:

The frequency meter circuit is based on the AVT-2269 kit with minor modifications. However, half of the system is used, because in the designed device measuring the frequency up to 1kHz it is fully sufficient (3 seven-segment displays). The task of the meter is to count the pulses in a given time unit and display them on the display. The meter is clocked with a quartz-stabilized generator with a frequency of 32.768kHz. This frequency is divided by 214, which gives 2 Hz at its output, and then on the two D-type monostable flip-flops by 4, which gives a waveform with a frequency of 0.5 Hz, in which the low and high states last one second. During the high state, the logic gate is open and the second input is influenced by the measured signal. It is then counted by the counter, snapped with a LATCH latch and displayed on the seven-segment displays that are multiplex-controlled. The entire cycle is repeated every second. The arrangement in practice did not cause any major problems, but it is extremely capricious. It needs a very stable power supply (a small variable component caused incorrect operation), and a supply voltage of 5V, although the integrated circuits used can work up to 15-18V. At a voltage higher than 5V, even by half a volt, the system freezes, stopping the previously indicated value and stays in the latch. The measured signal must also have a strictly defined voltage amplitude (4.2V-5V), therefore, in order to extend the possibilities of measuring signals to 15V, the measured voltage stabilization (peak cut) was applied to the value of 4.7V on the Zener diode. The maximum relative error of the frequency measurement of the system is 0.1% + 1 significant digit. In order to calculate the error, the system was compared with the TCX0-5 reference made according to L-18 / WT-6860-074.

Schematic diagram of the frequency meter:

Power system:

The power supply provides 9V for the generator, 5V for the frequency meter circuit, and 3.3V for the LED operating diode. The output voltages are very stable. The TL413 chip was used to obtain the reference voltage. Its value is set to 9V and then divided to 5V and 3.3V by voltage dividers. Voltage from 10.5V to 15V can be applied to the input of the power supply for the unchanging parameters of the entire system. The range covers the voltages that may occur in the automotive installation. The reference voltage, after filtering on the capacitors, goes to the positive inputs of the LM324 operational amplifiers. These amplifiers control the output transistors directly, and their negative inputs have output voltages. The operational amplifier always tends to the "virtual zero" between the positive and negative inputs, so all changes in the output voltages are compensated by them, so that the output is always, regardless of the load and temperature, the set voltage with a high accuracy. The additional capacitances filter out the voltage and allow time for the feedback (which is itself very fast) to respond to current pulses. Such pulses are taken by an executive LED diode, so its voltage must be rigid so that there is no fading effect during operation.

Schematic diagram of the power supply:

Cool? Ranking DIY