Hello,

as Christmas is fast approaching, I would like to present you an egg printer (in the sense of Easter eggs

I designed all the necessary elements of the structure in SketchUp and printed it on a 3d printer. Green from ABS, orange from PLA. Unfortunately, I do not know for what reasons, but I struggled with designing the electronics housing and it is a good centimeter too big. I did not want to change anymore and I left it like that

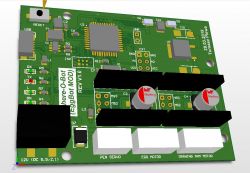

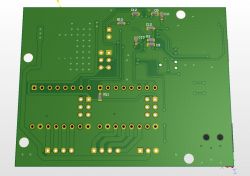

The driver is an Arduino nano with GRBL software loaded, for this A4988 stepper motor drivers and recovered motors. They could be much smaller and weaker, but that's what I had. The pen is controlled by a micro servo, and the limit switch is a slotted optocoupler (also from the drawer).

The use of a servo carries a slight inconvenience, or two. First, you need to modify the GRBL library by uploading a servo instruction file. Secondly, each time you generate a Gcode file, you need to process the file again. The postprocessor converts the commands to raise and lower the pen. Everything is described quite nicely HERE .

There is actually nothing to write too much about here. If you need more details, please ask in the comments.

Summing up the project, it is admittedly a bit too early for me to wish you a happy "Hallelujah".

Below are some videos and photos:

I don't have any sensible video editing program so I have no way to speed up videos. So I suggest you click on the settings immediately and increase the playback speed.

Cool? Ranking DIY

but of course the easier the better.

but of course the easier the better.