For my own purposes, I made a wire cutting machine to complement the electronic boards I offer for model railways. The premise was to cut the wires to a set length and quantity.

Electronics .

To speed up the build, instead of making a PCB I used off-the-shelf solutions: a CNC shield for an Arduino nano with two stepper motor controllers. To this attached after I2 a 16x2 display and a membrane keyboard (ready-made from Alliexpress).

Mechanics .

After reviewing similar solutions, I decided to feed the wire with the mechanics of an extruder from a 3D printer. As the kynar is thin and quite delicate, the drive had to be modified: the toothed roller has grinded teeth, and instead of a concave roller I put a bearing. To prevent the kynar from slipping off the rollers, I glued a truncated meat injection needle onto the input. On the exit, instead of a piece of bowden - a piece of pen nib. The last two modifications ensured stable guidance of the flexible cable.

I carried out the cutting with scissors - a very important advantage of this solution is that after cutting you can continue with the closing movement of the pliers, unlike with typical clippers. There are Stanley clippers available, or replacement clippers that work with scissors, but I don't need to cut thicker wires, plus the scissors were easy to attach. Scissors without handles mounted in a 3D printed mount, the movable arm has a handle instead of a handle, which is articulated to a wheel attached to a stepper motor. The motor is arranged so that it can perform a full rotation freely. The whole, unlike the solution based on clippers, is not sensitive to the wear of the mechanism, its play, etc. (the scissors do not close at zero, they make a further movement, which will always eliminate tolerances, the influence of wear, etc.).

Motor mounts from 3D print, Roller on kynar - 3D print reinforced with M3 pin. Display and keyboard in canopy 3D print, all encased in foamed PVC.

Firmware .

The display shows a menu where you select the variant to be cut, then the number of wires or sets per board. In the next step, the program moves the wire according to the preset length and then the stepper motor responsible for cutting performs a full rotation. The cycle repeats itself a pre-programmed number of times, and the start of the programme always begins by cutting the excess wire so that the first section is exactly the set length.

The last menu item allows the length of the sections to be cut to be specified manually.

What I would change .

I would reverse the cutting motion - so that the movable arm cuts downwards rather than upwards - here I needed to eliminate the scattering of cut fragments by the canopy tray catching the tossed fragments.

At the back of the case I would have given space for the power supply, so as to store the whole thing in a compact form.

BOM

Arduino Nano 10 zł

CNC Shield 12 zł

2x stepper motor controller 18 zł

display 1602 with I2C expander 10 zł

membrane keyboard 5 zł

2x ENema17 stepper motor with cables 22 zł

12 V power supply from demobilu

scissors from demobilu

M3 screws, washers, nuts from drawer

2 sheets of foamed PVC 60 zł

(prices from alliexpress, allegro)

A video of how the device works:

.

Assembled device:

.

.

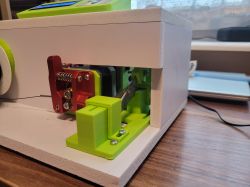

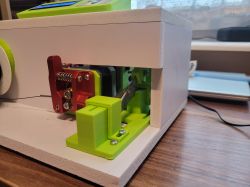

Kynar feed drive:

.

.

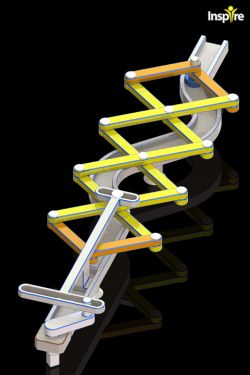

Cutting drive:

Cutting drive.

Cutting drive.

Entire mechanism:

.

.

Back of case

Electronics .

To speed up the build, instead of making a PCB I used off-the-shelf solutions: a CNC shield for an Arduino nano with two stepper motor controllers. To this attached after I2 a 16x2 display and a membrane keyboard (ready-made from Alliexpress).

Mechanics .

After reviewing similar solutions, I decided to feed the wire with the mechanics of an extruder from a 3D printer. As the kynar is thin and quite delicate, the drive had to be modified: the toothed roller has grinded teeth, and instead of a concave roller I put a bearing. To prevent the kynar from slipping off the rollers, I glued a truncated meat injection needle onto the input. On the exit, instead of a piece of bowden - a piece of pen nib. The last two modifications ensured stable guidance of the flexible cable.

I carried out the cutting with scissors - a very important advantage of this solution is that after cutting you can continue with the closing movement of the pliers, unlike with typical clippers. There are Stanley clippers available, or replacement clippers that work with scissors, but I don't need to cut thicker wires, plus the scissors were easy to attach. Scissors without handles mounted in a 3D printed mount, the movable arm has a handle instead of a handle, which is articulated to a wheel attached to a stepper motor. The motor is arranged so that it can perform a full rotation freely. The whole, unlike the solution based on clippers, is not sensitive to the wear of the mechanism, its play, etc. (the scissors do not close at zero, they make a further movement, which will always eliminate tolerances, the influence of wear, etc.).

Motor mounts from 3D print, Roller on kynar - 3D print reinforced with M3 pin. Display and keyboard in canopy 3D print, all encased in foamed PVC.

Firmware .

The display shows a menu where you select the variant to be cut, then the number of wires or sets per board. In the next step, the program moves the wire according to the preset length and then the stepper motor responsible for cutting performs a full rotation. The cycle repeats itself a pre-programmed number of times, and the start of the programme always begins by cutting the excess wire so that the first section is exactly the set length.

The last menu item allows the length of the sections to be cut to be specified manually.

What I would change .

I would reverse the cutting motion - so that the movable arm cuts downwards rather than upwards - here I needed to eliminate the scattering of cut fragments by the canopy tray catching the tossed fragments.

At the back of the case I would have given space for the power supply, so as to store the whole thing in a compact form.

BOM

Arduino Nano 10 zł

CNC Shield 12 zł

2x stepper motor controller 18 zł

display 1602 with I2C expander 10 zł

membrane keyboard 5 zł

2x ENema17 stepper motor with cables 22 zł

12 V power supply from demobilu

scissors from demobilu

M3 screws, washers, nuts from drawer

2 sheets of foamed PVC 60 zł

(prices from alliexpress, allegro)

A video of how the device works:

Assembled device:

.

.Kynar feed drive:

.

.Cutting drive:

Cutting drive.

Cutting drive.Entire mechanism:

.

.Back of case

Cool? Ranking DIY