FAQ

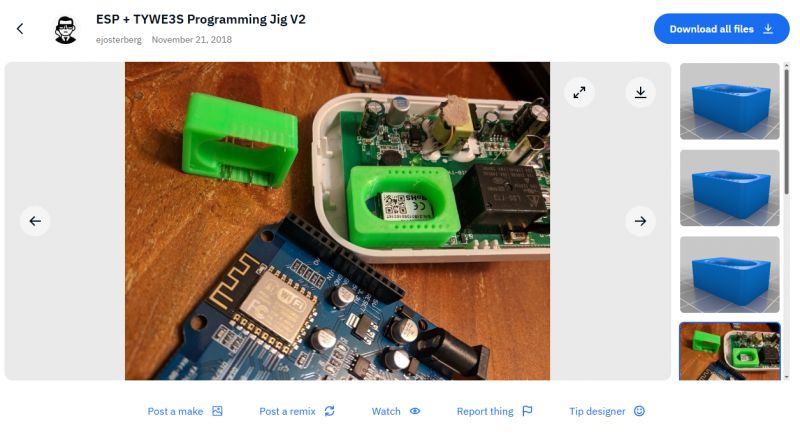

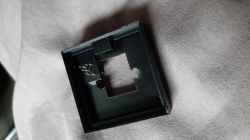

TL;DR: For ECR6600 smart plugs, a 3D-printed programming jig was printed with a 0.2 mm nozzle; "It was printed on a Bambu Lab X1 Carbon." STL links and photos are shared below. [Elektroda, jannie_doedel, post #21476597]

Why it matters: This helps DIYers decide between a jig and direct UART wiring, and grab community-tested models and pointers.

Quick Facts

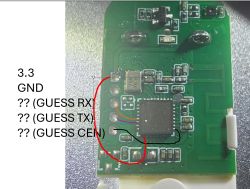

- UART0 pads on ECR6600 are often brought out, enabling direct flashing without a complex jig. [Elektroda, insmod, post #21473689]

- TYWE3S-style flashing jigs are a useful reference for beginner-friendly alignment and access. [Elektroda, p.kaczmarek2, post #21473692]

- A lightly modified Thingiverse 3615910 jig “worked amazing” for one contributor. [Elektroda, DeDaMrAz, post #21474466]

- Shared STL prints succeeded on a Bambu Lab X1 Carbon using a 0.2 mm nozzle (PETG). [Elektroda, jannie_doedel, post #21476597]

- ECR6600 backup/flashing guidance is still WIP; see the referenced thread for gleaned steps. [Elektroda, divadiow, post #21477988]

Do I need a 3D‑printed jig to program an ECR6600 plug?

Not always. "ECR6600 should have UART0 pins wired out," which reduces the need for a jig. If pads are reachable, wire TX/RX/GND directly. A jig mainly adds convenience and repeatability, especially for beginners or batch work. [Elektroda, insmod, post #21473689]

What is a 3D‑printed flashing jig in this context?

Think of the TYWE3S flashing jig: a helper tool used to flash modules without soldering small pads. The same idea inspired this ECR6600 effort for easier, more consistent contact during programming. It targets beginner-friendly alignment rather than advanced probing. [Elektroda, p.kaczmarek2, post #21473692]

Is a chip‑level jig realistic if the board uses a bare ECR6600?

Creating a jig that presses onto a bare, tiny chip is impractical. The small geometry makes reliable contact and alignment doubtful. If no module or accessible pads exist, consider traditional soldered leads to pads instead of a jig approach. [Elektroda, insmod, post #21473699]

Are there model files and photos I can use right now?

Yes. Photos and STL files were posted. They were printed on a Bambu Lab X1 Carbon using a 0.2 mm nozzle in PETG. "It was printed on a Bambu Lab X1 Carbon with 0.2 mm nozzle in PETG." [Elektroda, jannie_doedel, post #21476597]

Which jig design already worked well for people here?

A lightly modified version of Thingiverse model 3615910 was reported as successful. The contributor noted it "worked amazing" for flashing. You can request the model files if you want to replicate their setup. [Elektroda, DeDaMrAz, post #21474466]

How do I print and test the shared jig models?

- Download the STL files shared in the thread.

- Slice for PETG using a 0.2 mm nozzle, matching the demonstrated setup.

- Print and verify the fit on your device during your programming workflow.

[Elektroda, jannie_doedel, post #21476597]

I don’t own a 3D printer—what are my options?

You can still program via the exposed UART0 pads, so a jig is optional. Wire a USB‑UART adapter to the TX/RX/GND pads and proceed with your chosen tool. This keeps costs down and avoids printing altogether. [Elektroda, insmod, post #21473689]

Is Ender 3 PRO a good budget choice to print the jig?

It works but needs attention. "Ender 3 PRO does not take much space," yet expect periodic fixes and calibration. The model is aging, so consider newer printers if you want less tinkering. Only choose it if you can maintain it. [Elektroda, p.kaczmarek2, post #21473688]

How do I back up the stock ECR6600 firmware?

A complete guide is pending. Backup and flashing steps can be gleaned from the referenced thread. ECR6600 is a work in progress, so verify each step and confirm your dump before flashing. Follow that discussion for current tools and notes. [Elektroda, divadiow, post #21477988]

Are step‑by‑step ECR6600 flashing guides coming?

Yes. A maintainer offered to prepare a guide if someone shares tested flashing details via PM. You can help by validating steps on your hardware and sending logs and notes. That speeds up documentation. [Elektroda, p.kaczmarek2, post #21478105]

Can TYWE3S jigs be adapted or used as inspiration?

Yes. The TYWE3S jig example was shared as a beginner‑friendly reference. It shows how a printed fixture can simplify pad access during flashing. Use it as a starting point for ECR6600‑specific adaptations. [Elektroda, p.kaczmarek2, post #21473692]

Where can I verify if my plug matches known ECR6600 boards?

Check the linked discussion that catalogs similar devices. A contributor suspected the posted plug matched those examples. Compare your PCB photos and markings against that thread to confirm. [Elektroda, divadiow, post #21473698]

Who in the community is involved in this effort?

Contributors include p.kaczmarek2, divadiow, insmod, and others. The thread also references prior jig work by DeDaMrAz for Beken. Tagging these users can surface prior art and tips. [Elektroda, p.kaczmarek2, post #21473645]

Can I contribute a 3D design if I’m not into soldering?

Yes. The thread welcomed a 3D design contribution specifically for reading/programming the new plug. Sharing STLs, photos, and print notes helps others avoid soldering and speeds testing. [Elektroda, jannie_doedel, post #21473510]

.

.