CNC plotter with drag knife + CAM software

Today I present a CNC machine - a plotter with a drag knife which I made for my own use (for my spouse).

The spouse designs and cuts out decorations from paper. So far, he uses the Brother Scanncut plotter. The machine works quite well, although after cutting, I think that already thousands of decorations show some wear. In addition, it works quite loudly, which is a bit disturbing because the studio is at home (the engines probably work at full speed, the housing vibrates a lot) is slow and the working area sufficient for an A3 sheet has started to be insufficient.

A decision was made to build a new machine with a larger working area.

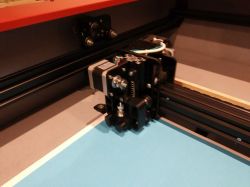

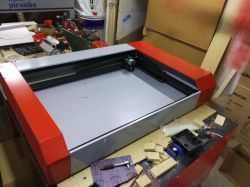

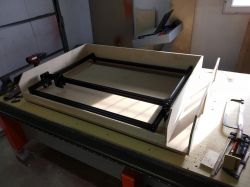

Initially, the idea was for a laser. Despite my concerns about inserting the laser into the house (need for extraction, flammable material, etc.), I took the first steps. I bought a 30W laser and to speed up my work a bit, I also bought a 165 x 85 cm frame according to the openbuilds project. In the meantime, however, it was decided that a drag knife would be the best solution for this application. The already purchased frame, a bit too flexible for a drag knife, but for the one without the Z axis, I decided to use it. I made the Z axis myself, a trolley with a head holder printed on a 3D printer. I strengthened the frame and mounted it in the reverse position. Initially, I wanted the axle to be light and I wanted to use a modeling servo as a drive (see the photo), but I quickly found out that it was a bad idea. Finally, the Z axis drives the stepper motor, the pressure of the knife by a push back spring.

The housing is mainly plywood and MDF (used scraps and waste that I had) and 0.5mm steel sheets as covers. There is also a table with shelves for mats and paper.

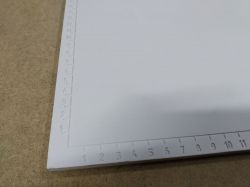

The paper mats are 6mm foamed PVC with scales engraved on the milling machine to make it easy to arrange the paper.

Controls are GRBL and CNC Shield, on Universal gcode sender computer.

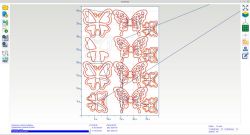

Since it was hard for me to find a tool that would be simple, easy and quick to generate the toolpath, I did my job. This is the program I called CuterCam and it was this stage that took the longest (about 1.5 months).

The program loads a dxf or svg drawing, detects the shapes itself, determines the order based on the algorithm. Shapes can be moved, rotated, duplicated, deleted, hidden, grouped etc. and arranged freely on the selected mat. In fact, it takes just a few clicks and the g-code is ready for a very complicated drawing. The program has a wizard of post-processors, you can create and save many of them. Shapes are cut out according to one of 3 algorithms:

- internal first

-external first

-nearest shape

In addition, the program allows you to control the angle of the knife entry. After completing the previous shape, the program saves the knife setting angle (angle of the last vector of motion) and starts the next shape from the place where the angle of the first vector of motion is as close to it as possible. This allows the knife to be lowered immediately to the cutting direction, it does not have to turn back in place, so there is no risk of breaking it or tearing the material out when turning.

Below are some photos that have survived from the construction and a video of cutting out and the work of the CuterCam program.

Comments

I don't know anything about it, but wouldn't an ordinary servo (control 0, 1) be enough for the Z axis? The advantage would be to reduce the weight of the ambulance. [Read more]

How did you solve the knife contact pressure adjustment and cutting depth for different materials? Typically these applications use a coil and you have a stepper motor. [Read more]

Gentlemen, I don't think you've read it :) Originally there was an idea to use a servo (you can see it in the photo) but it was too slow and too weak (you killed yourself by lifting the head pressed... [Read more]

Write something more about underlays, how the underlay sticks to your table and how the undercoat sticks to your table. [Read more]

The mat is made of 6mm thick foamed PVC. I have mats in sizes A3, A2 and A1. The mat is simply placed on the table against the base stops (Left and Bottom). On the right and top there are locks with butterflies.... [Read more]

Please write me what is this glue? Could this foundation be thinner? Do you buy ready-made ones with measuring cups, or do you somehow mill the measuring cups yourself? [Read more]

Temporary glue for paper, on but ... it's full of it. The backing could be thinner and it could be thicker :) I chose 6mm because I thought it would be thin enough not to be too expensive and thick... [Read more]

And everything is clear. When it comes to holding the paper, I repaired the plotter (drawing in ten different colors with pens) several times, probably Roland, where the worktop was made of "electrifying"... [Read more]

I have to be interested in this because it sounds interesting. The glue is good and reliable, but every few dozen sheets of mate you have to clean and apply glue. When drawing, the forces on the paper... [Read more]

I have exactly this Roland, and I have the same frame as the author. That is why I am asking, because the PVC would stick electrostatically thin and the paper with glue. [Read more]

Looking at the date of your joining the group of our forum members, I do not exclude that your plotter could also be hosted on my operating table at one time. :) . Unfortunately, I had the last case of... [Read more]

I am 32 years old and have known the stories of this plotter since almost I was born. He was at the Lodz University of Technology, he had a converted holder in which you put a marker pen and drew PCBs... [Read more]

I do not know what model you have, but somewhere I saw Roland's plotter drawing, he was murdering himself terribly, in the sense he drew all the gaps with lines and he slowed down terribly. Additionally,... [Read more]

I associate the number 980 in the name with something. That's right, when I drew a PCB in protel99 and it was controlled by the Windows driver, it was a bit like that. But with the Autotrax, or rather... [Read more]

Great performance ;) I am planning to make such a plotter for cutting stickers for models in a 1:14 scale. In my concept, it will be a cutting plotter on a roller because the foil is rolled up and it is... [Read more]

There is no shortage of plotters that cut the foil from the roll. I don't know if it will pay off wasting time building your own, unless there are specific requirements that trading plotters do not... [Read more]

I know, but I do all the machines myself, such a deviation ;) I don't need a plotter for profit and hobby purposes, so the economy doesn't matter here :D Greetings [Read more]

It's not about earnings, but you'll probably get one for free or for PLN 100-200. I had two old A1 cars and they were scrapped last year because there were no volunteers. [Read more]

Ok, I suggest you respect your friend's thread and not drag on Offtop ;) Greetings [Read more]