Hello

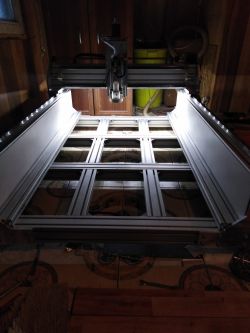

I present my next CNC milling machine which I have not finished long ago.

The purpose is mainly: milling, engraving, cutting in materials such as:

- wood

- mdf

- plexiglass

The main assumptions are: a large working field combined with the stiffness of the structure and good material processing parameters.

and it happened, the working field is:

X = 1000mm

Y = 1500mm

Z = 190mm

External dimensions

width 1400mm

length 1850mm

620mm height

Work on the project began in August 2018, construction and storage of elements in the area beginning of October 2018

So

The structure is made of aluminum profiles 60x60x30 (L-shaped), additionally vertical profiles 60x30.

In addition, I used reinforcements at right angles made of 10mm aluminum, which facilitated the assembly of the whole,

in the back part I just bothered an extra strengthening broom.

In the front I gave up what did not affect the stiffness of the structure, thanks to which it is easier to transport the material to the worktop.

The worktop is a 22mm chipboard from the bottom, additionally stiffened and bolted to the 60x30 profiles, preventing the tabletop from bending.

The material is fixed to the top by means of handles and M8 screws to 176 muffs in pre-drilled holes in the worktop and additionally glued.

From the inside, the 5mm plexiglass is mounted as a dust-proof cover.

On the right side of the machine, I mounted the electronics using 4mm aluminum sheet + rubber shock absorbers for screws for aluminum profiles.

The frame is also based on aluminum profiles and sides of 20mm aluminum

X-axis

rollers supported over the entire length of 20mm + linear bearings

drive: ball screw 2010 + 20mm supported spindles + linear bearings: 4Nm motor

Y axis

drive: 2x ball screw 2010 + 2x stepper motor 4Nm

Z axis

Roller supported 16mm ball screw 1605 and aluminum sheet 15mm, motor 3Nm

On the bottom profile I installed 15 LEDs for lighting.

Electronics:

Control via raspberrypi directly without GPIO, all axes have TB6600 (original) drivers set to split 1/8

power supply: 800VA 30V AC transformer (DC ~ 42V)

Drivers for TB6600 engines

1.5kW air-cooled spindle, + Sanyu inverter with which the control via RS485 with raspberrypi is carried out with the modbus protocol

Thanks to this, I have a preview of parameters such as:

DC bus voltage

Output voltage

Output current with an accuracy of 0.1A

Frequency

Temperature of the inverter

and full configuration of the inverter parameters from the software level I wrote on raspberrypi to control the whole

I wrote a service program in delphi 7 and communication with rPi is done using TCPIP

The driver PCB includes:

16 opto-isolated inputs

16 OC OC outputs

1 relay

2 x Mosfet with PWM, 1 channel for TB6600,2 controllers for the spindle where I disassemble the upper part for a long time by installing a fan + temperature sensor for the spindle itself

The machine achieves travels of about 6m / min which is fully enough for me

Below the photos (sorry that the part is hardly visible, I worked mainly at nights and the camera hardly caught it)

Cool? Ranking DIY