.

.

Hello my dears .

I recently got my hands on two Ania R612 radio receivers made by Unitra. Here I will show their interior, give clear pictures of the boards with commentary and post the full manual and catalogue notes of the components that are inside.

Introduction and teardown .

I rescued both radios from electro-waste, someone just wanted to throw them away. I know they don't have much value, but I have a lot of respect for Polish technical thought and old Unitra equipment, so I couldn't leave them like that, even though they were in quite poor condition - no antenna, broken handle, dirty casing:

.

.

The radio on the front has three knobs:

- range selection (UKF/K/S/D)

- tuning

- volume (with switch)

The rear presents itself as follows:

.

.

On the back we have:

- space for batteries (5 R6, 7.5V)

- connector for 230V power cable

- headphone connector

There is also the information Power Consumption: 3W.

Fortunately, there were no batteries inside, although the condition of the contacts on one of the radios indicated that they had probably spilled out in there before.

.

.

The case is held on by four flathead screws:

.

.

Care must be taken when opening - the cable from the antenna prevents the cover from being removed initially:

.

.

Fortunately the antenna connection can be removed:

.

.

Then the two parts of the housing are already held on by just two wires from the power supply:

.

.

.

.

Both radios open in one photo:

.

.

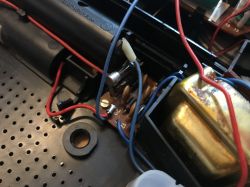

Inside, what immediately catches the eye is a large ferrite antenna, typical of such older receivers. Next to it we have a 1W 8Ω Tonsil GD8/1/2 loudspeaker. Directly on the main board is the jack connector from the headphones, and there is also another characteristic element, the adjustable capacitor (actually there are several trimmers inside it, not one).

On the rear cover side is a separate board with a fuse and Greatz bridge. What was striking to me here was that the fuse was out of place - the radio must have fallen to someone.

.

.

.

.

The transformer can be removed, it is only held on by a plastic clip.

Signed is:

UNITRA ZATRA

TS2/22 .

The main PCB has on board two ICs.

UL1219 (equivalent to TDA1220B, heterodyne IC and A.M. mixer AM/FM intermediate frequency amplifier, AM/FM detector):

.

.

UL1497 (low-frequency amplifier; a loudspeaker is connected to it):

.

.

There are also transistors; BF195:

.

.

Diode 811 (BAP-811):

.

.

By the way, I noticed that one of the electrolytic capacitors no longer holds on to its solders (as I mentioned earlier, the radio must have fallen to someone):

I later corrected these solders.

In order to remove the main board from the housing, you have to unscrew the screws holding it in place and then additionally remove the three knobs from the front of the radio:

.

.

.

.

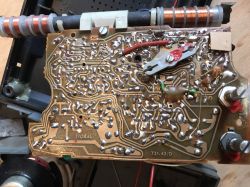

After that, you can already admire its paths from below:

.

.

The paths on this board in no way resemble what we have in the devices now - they were probably run by hand, although who knows? Maybe someone reading this knows more about how these PCBs were made and will share the details.

.

.

Also visible here is the tuning mechanism with the cable:

.

.

.

.

Here, remember not to move the tuning after removing the electronics board, as the tabs on the plastic tuning piece must match the trimmer when fitting the radio back together.

One of the radios had a section of the ferrite antenna PCB broken off:

.

.

.

.

As a result of this, one path with a resistor was also damaged:

.

.

I immediately glued the PCB together and repaired the path with a tin bridge:

.

.

First voice .

This was not the purpose of this article, but after the minor adjustments described in the previous paragraph I managed to get the first voice out of both radios.

The result in the videos:

You can hear the cringing and from a distance you can see that there is still a lot of work left to restore them to good condition, but I'll talk about that in another topic.

Need to tune the receiver .

It is worth noting here that the Annie R612 receives on the UKF range 65.5 - 74MHz (the OIRT band; the so-called "lower band"), and these days stations transmit on the CCIR range (87.5 - 108MHz). The 65.5-74MHz band was used in Poland until 31 December 1999, so it's unlikely we'll be able to listen to much UKF on it without some tuning. However, this is not the subject of this post, and I am yet to undertake the tuning, so I will only write about it in a little while.

Rebranding and Anna R612 for export .

The radio from the topic was not only available in Poland. For example, in Germany it was available under the name Nordmende Essex 1654 or there in Czechoslovakia as Anja RT-432. Interior identical. You can read more about it here:

https://www.radiomuseum.org/r/eltra_anja_rt_432.html

https://www.radiomuseum.org/r/nordmende_essex_1654_986136_h_76986.html

Manual from Unitra .

Almost as impressive as the radio itself is its manual - downloadable here in the appendix:

.

The manual includes the date - 1986 - which is over 30 years ago.

.

.

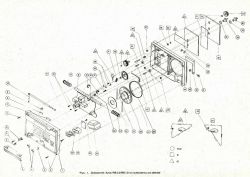

The manual has what is called an 'exploded view' - a breakdown of all the radio components/details:

.

.

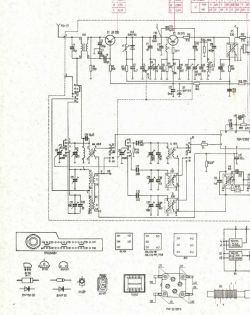

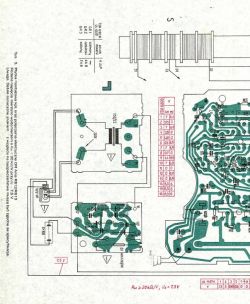

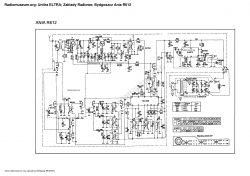

In the manual there is, of course, a schematic diagram - but both the idea version and the with PCB:

.

.

.

.

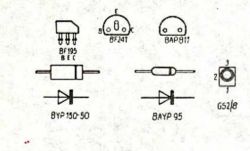

There are even component leads described:

.

.

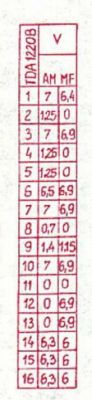

Voltages are also given, even those on individual IC pins:

.

.

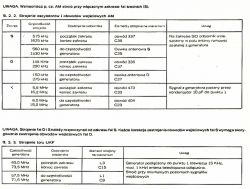

Extremely detailed radio reception parameters are available:

.

.

Details of tuning and associated components are also described:

.

.

In conclusion, the documentation of the Ania R612 receiver from Unitra in no way resembles the documentation of the equipment produced nowadays. It is very detailed and one gets the impression that it is written with the intention of making it easier to service and repair the receiver, so that it can work for a really long time.

Attachments .

I enclose here the catalogue notes of the components found in this receiver.

BAYP95:

.

BF194/BF195:

.

BF240:

TDA1220B (counterpart UL1219):

.

UL1497/UL1490N:

.

BAP811:

.

Radio diagram itself:

Summary .

In this topic I have essentially limited myself to depicting the interior of the Ania R612 receiver. I also intend to get into its restoration and tuning in the future, but that's in another topic.

In the meantime I invite you to comment - do you have any memories or anecdotes related to old Polish radios? Maybe some technical details? Or maybe someone will provide pictures of the inside of their receivers (hopefully in better condition than mine)?

Cool? Ranking DIY Helpful post? Buy me a coffee.